Pressing die for meter housing

A technology for pressing molds and instrument shells, which is applied in the field of instrument processing equipment and instruments, and can solve problems such as low work efficiency and laborious unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

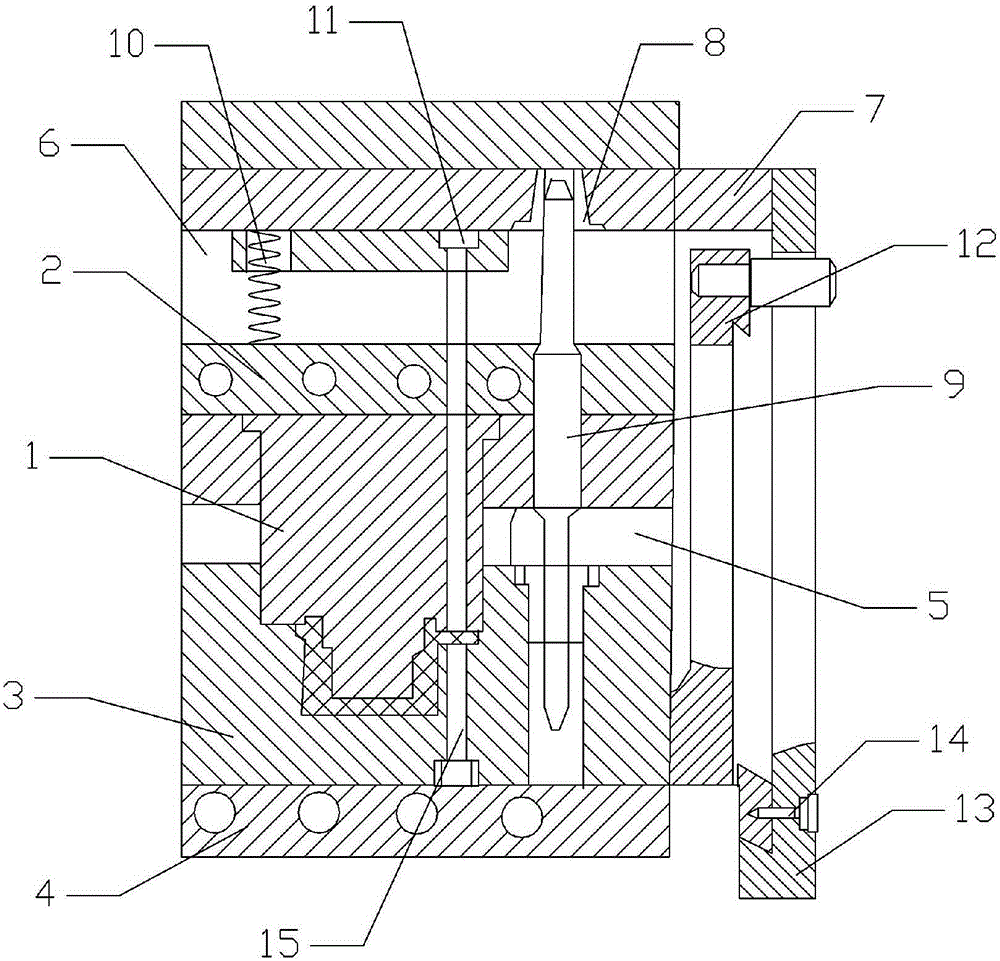

[0012] The reference signs in the drawings of the description include: punch 1, upper heating plate 2, concave mold 3, lower heating plate 4, pressure bearing plate 5, upper support plate 6, upper ejection plate 7, guide sleeve 8, guide post 9 , spring 10, push rod 11, limit plate 12, pull-up plate 13, adjusting screw 14, molding core 15.

[0013] The embodiment is basically as attached figure 1 Shown: a pressing mold for an instrument case, including an upper heating plate 2 with a punch 1 installed, and a lower heating plate 4 with a die 3 installed, a pressure plate 5 is provided between the punch 1 and the die 3, The upper heating plate 2 is connected with an upper support plate 6, and the upper support plate 6 is connected with an upper push-out plate 7, and the upper push-out plate 7 is provided with a guide sleeve 8, and the die 3 is provided with a guide post 9 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com