An anti-rotation and anti-retreat double-threaded hollow nail

A double-threaded, hollow screw technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve problems such as fixation failure, reduce the possibility of bending or fracture, improve structural strength, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

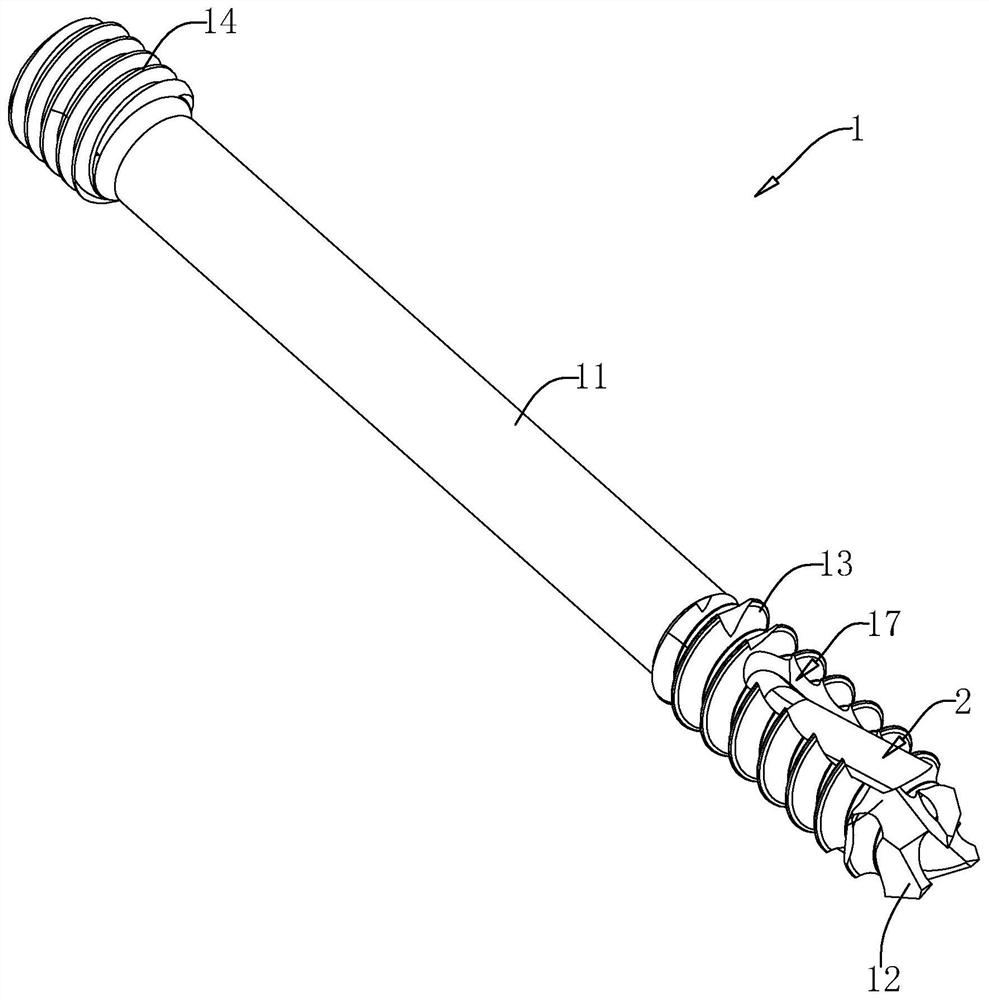

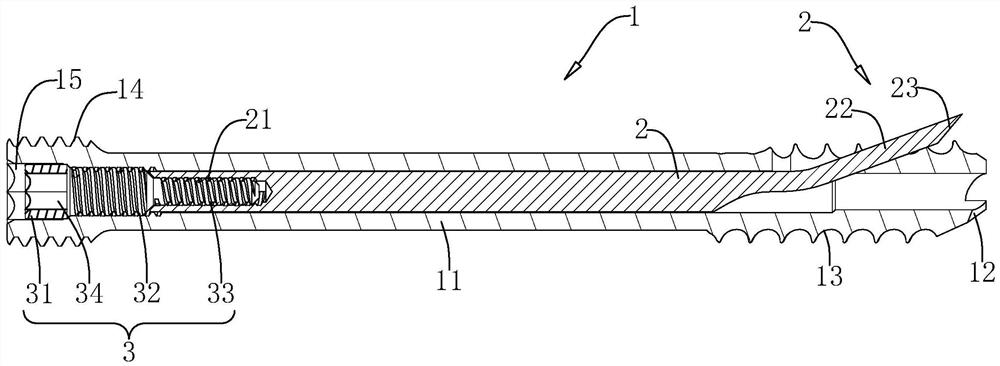

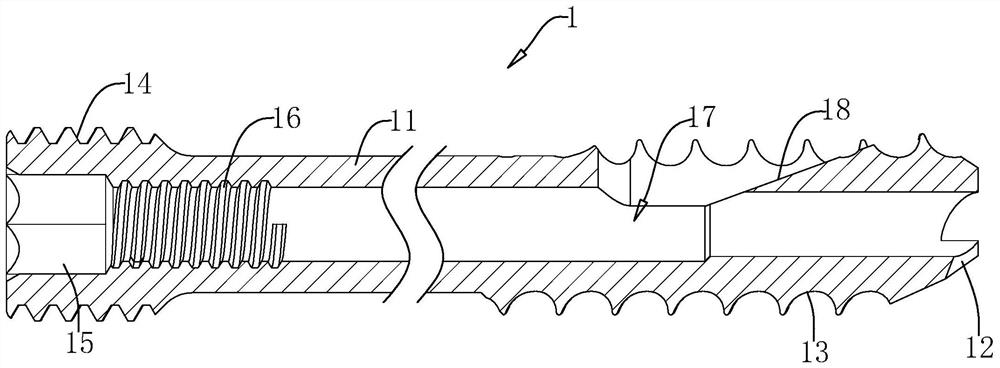

[0047] The embodiment of the present application discloses a double-threaded hollow nail with anti-rotation and anti-retreat. refer to figure 1 and figure 2 , the double-threaded hollow nail includes a screw body 1, a solid rod inner core 2 and a lock 3, all of which are made of titanium alloy material. Titanium alloy material has good biocompatibility, better strength and toughness, and meets medical requirements. Require.

[0048]The interior of the screw body 1 is hollow and open at both ends. During installation, it is positioned and guided by Kirschner nails; after the screw body 1 is in place, the solid rod inner core 2 is slid and plugged into the screw body 1 through a special supporting tool , used to strengthen the strength of the screw main body 1, and at the same time play the role of anti-rotation and anti-retreat, so as to ensure the stability of the double-threaded hollow screw after installation, and reduce the incidence of complications such as fracture non...

Embodiment 2

[0059] The embodiment of the present application discloses an anti-rotation and anti-retreat double-threaded hollow nail, which is different from Embodiment 1 in that it is a lock.

[0060] refer to Figure 6 , the lock 3 includes a sleeve 35 fixedly connected to the end of the solid rod inner core 2 away from the insertion rod 22 and having a diameter smaller than that of the solid rod inner core 2. The sleeve 35 is coaxially arranged with the solid rod inner core 2 and slides inside the sleeve There is a slide bar 36, and an anti-off structure is arranged between the slide bar 36 and the sleeve 35. The anti-off structure can be a position-limiting convex ring fixed on the inner wall of the sleeve 35 away from the end of the solid rod inner core 2 and the slide bar 36. The limit convex ring near the end of the solid rod inner core 2.

[0061] refer to Figure 6 and Figure 7 A cylindrical end cap 37 is affixed to the end of the slide rod 36 away from the sleeve 35, the out...

Embodiment 3

[0065] The embodiment of the present application discloses an anti-rotation and anti-retraction double-threaded hollow nail, which is different from the embodiment 1 in that the locking element and the inner core of the solid rod.

[0066] refer to Figure 8 , the lock 3 includes a lock head 31, a first threaded rod 32, a polished rod 41 and a limit post 42 which are coaxially arranged in sequence and integrally formed, and the diameter of the stop post 42 is smaller than the first threaded rod 32 and larger than the polished rod 41; the solid rod The end of the inner core 2 away from the insertion rod 22 is sequentially processed with a communication groove 24 and a limiting groove 25 inwardly along the axial direction. The limiting groove 25 is adapted to the limiting column 42. One radial side of the rod inner core 2 penetrates through.

[0067] refer to image 3 and Figure 8 , when installing the solid rod inner core 2, place the limit column 42 in the limit groove 25,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com