Platform assembly, digital light processing (DLP) 3D printer and demoulding method

A 3D printer and platform technology, applied in the direction of additive processing, can solve problems such as affecting the service life of the printer, skewing the printed object, increasing the cost, etc., to achieve the effect of ensuring the forming effect of the object, reducing the gas-hydraulic pressure, and ensuring the printing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

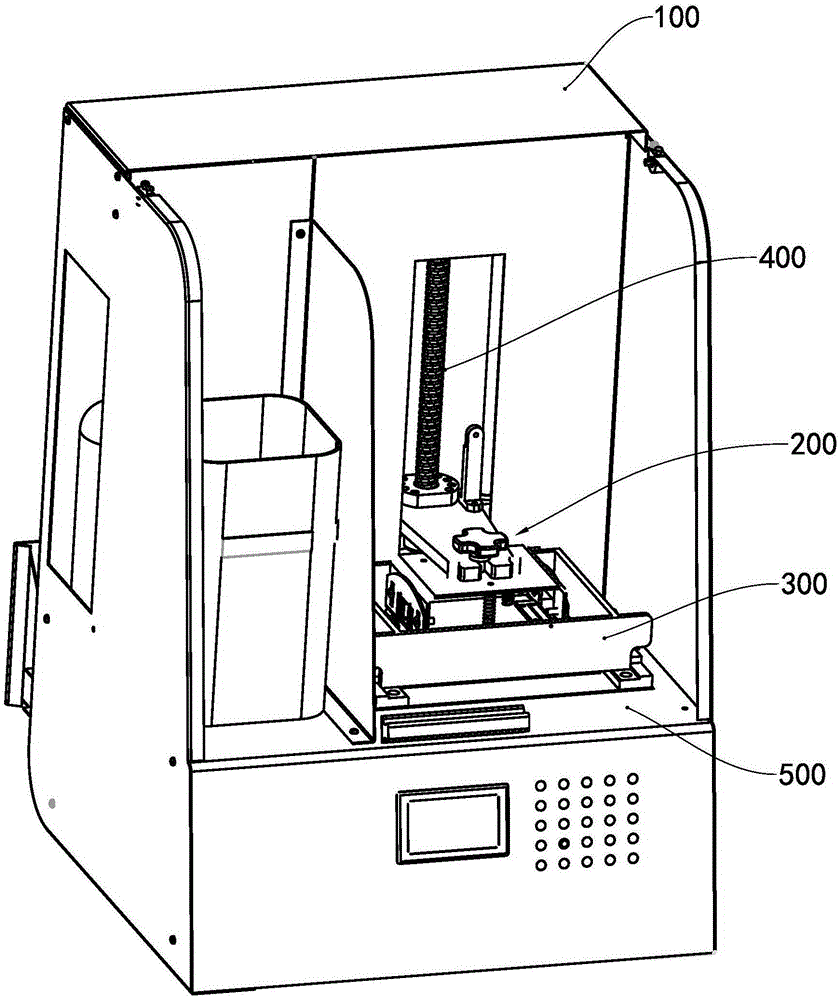

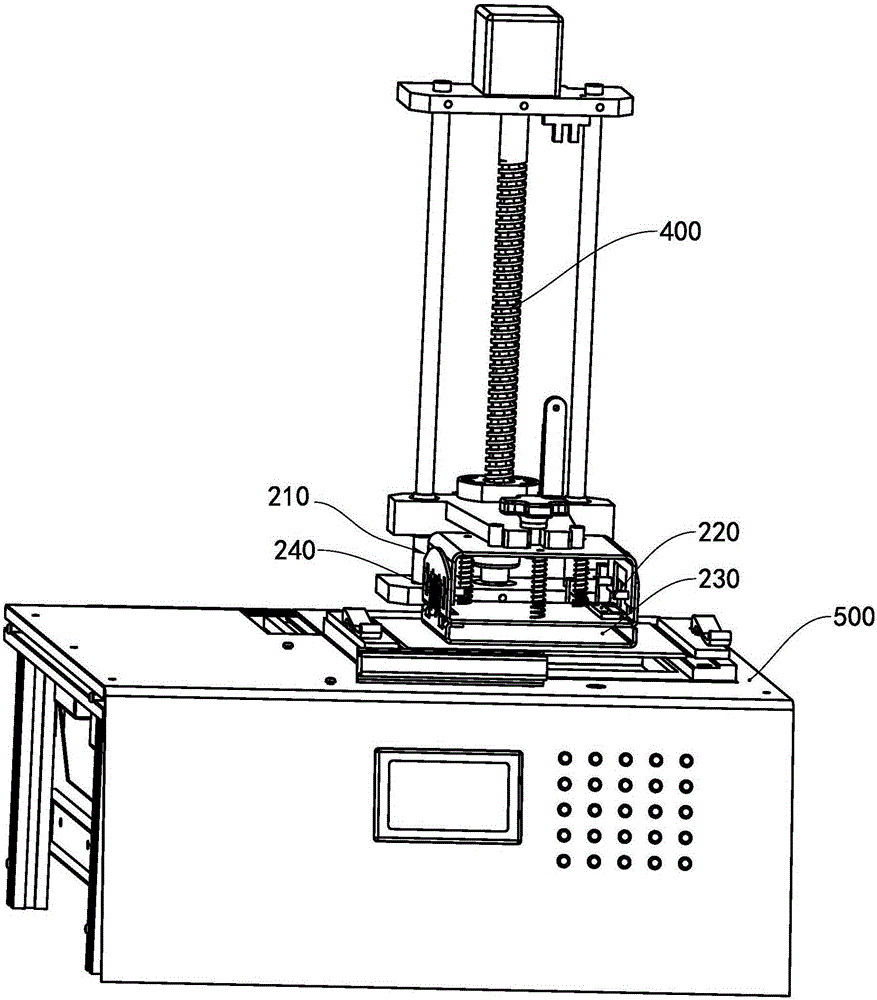

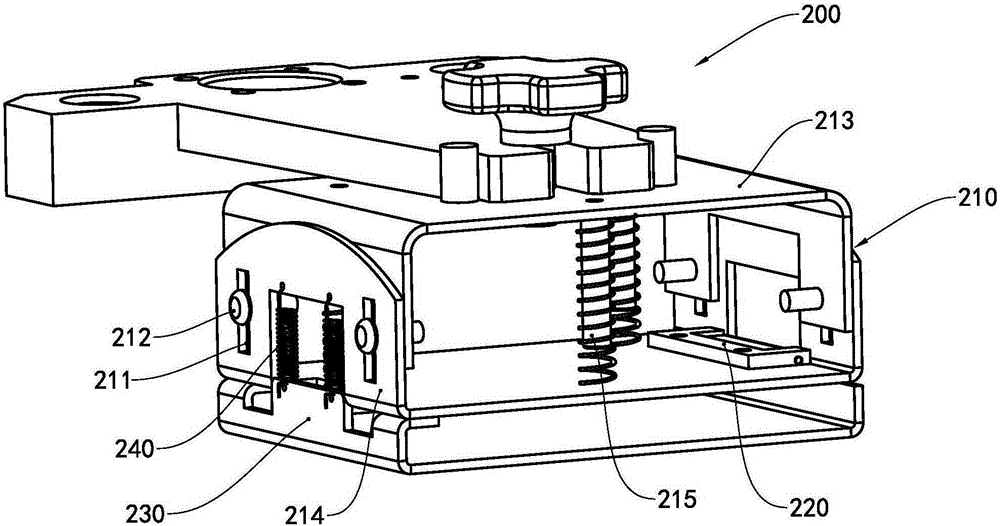

[0040] like figure 1 and figure 2As shown, the digital light processing three-dimensional printer of this embodiment includes a frame 100, a projector light source, a platform assembly 200, a screw drive mechanism, a workbench 500, a photosensitive resin tank 300 and a control system. The photosensitive resin tank 300 is placed on the workbench 500 in the frame 100 , driven by the screw drive mechanism, the platform assembly 200 can move up and down in the photosensitive resin tank 300 . The photosensitive resin tank 300 is generally made of transparent materials, which facilitates the transmission of light from the projector light source to the inside of the photosensitive resin tank 300 . An elastic material is laid on the bottom surface of the photosensitive resin tank, and the selected elastic material may be a silica gel material. The projector light source is arranged under the photosensitive resin tank 300 , and the photosensitive resin will be cured under the irradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com