Traction winding machine

A technology of winder and winder, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problem that the winding material cannot be flatly wound around the winder, affects the stability of the traction winder, and is The reel is prone to wrinkle and other problems, so as to achieve the effect of safe and reliable use, stable rewinding tension and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

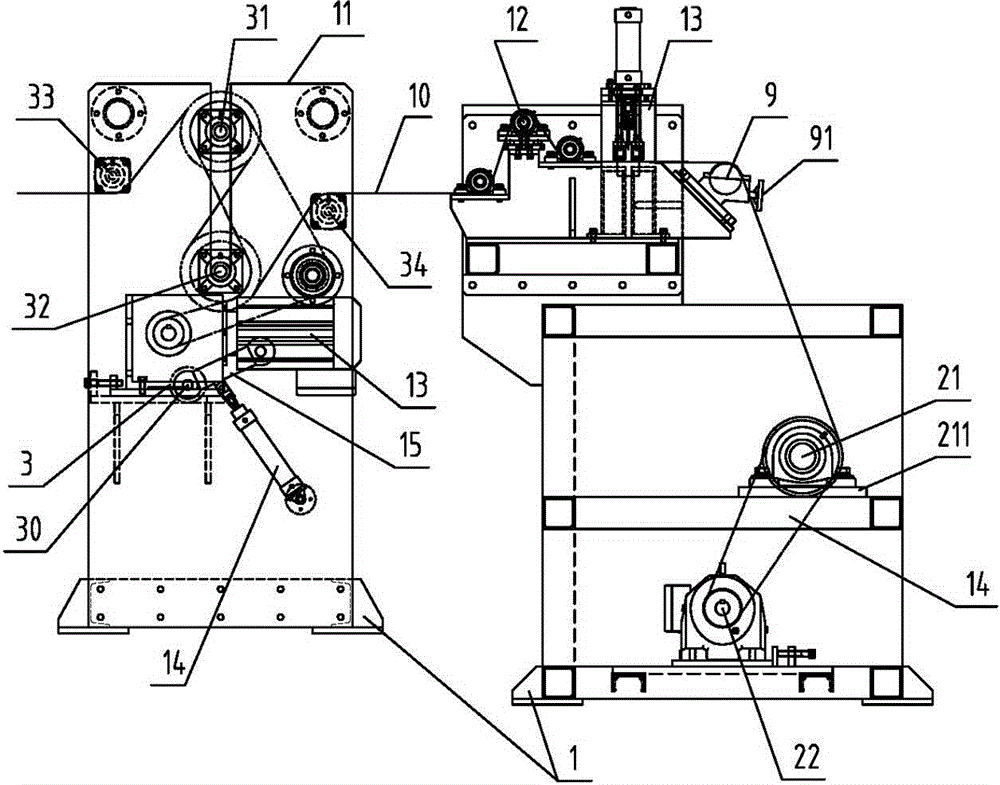

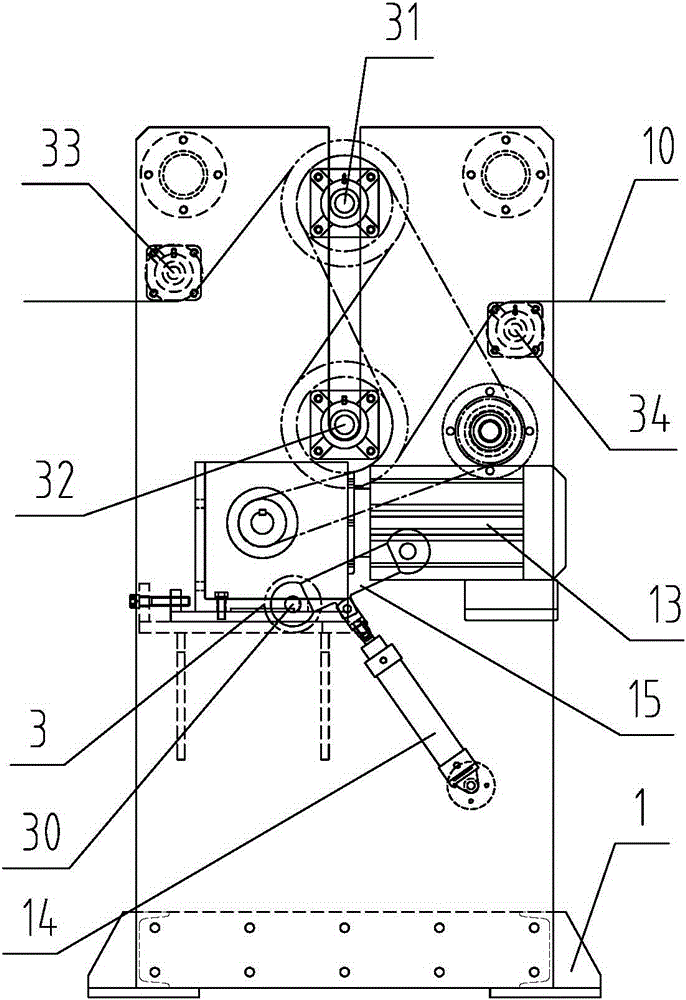

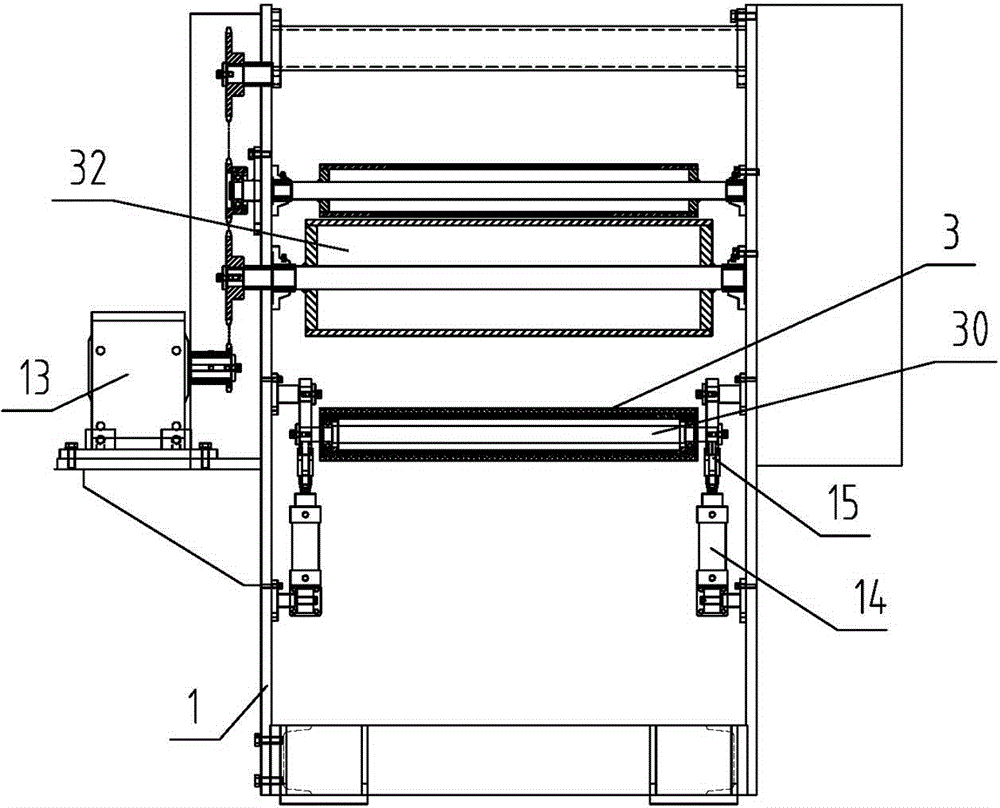

[0028] Here, the extrudate ready to be transported to the winding device for winding operation is called the object to be wound 10, and the extrudate that has been wound on the winding roller 21 is called the object to be wound. Such as figure 1 As shown, the traction winder of the present invention includes: a frame 1, on which a traction device 11, a winding tension adjustment device 12, a cutting device 13 and a winding device 14 are arranged. The winding device 14 includes a winding roller 21, the winding roller 21 is supported and arranged on the frame 1 through the third bearing seat 211, the winding roller 21 is driven by a frequency conversion motor 22, and the winding roller 21 can adopt an air-expanding shaft. The rewinding roller 21 mentioned above adopts a tile-type air-expanding shaft. Before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com