A box type annealing furnace

A box and box door technology, applied in glass production, etc., can solve the problems of reduced production efficiency, long annealing cycle, poor glass quality, etc., and achieve the effects of improving production efficiency, convenient operation, and shortening the retreat time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

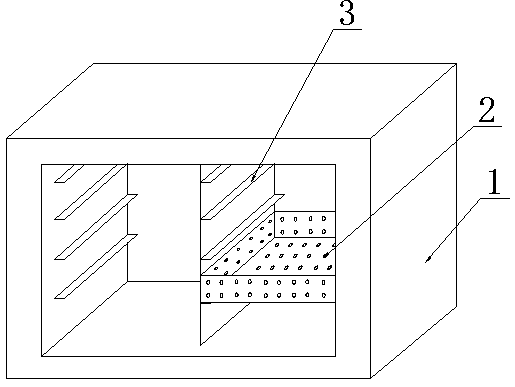

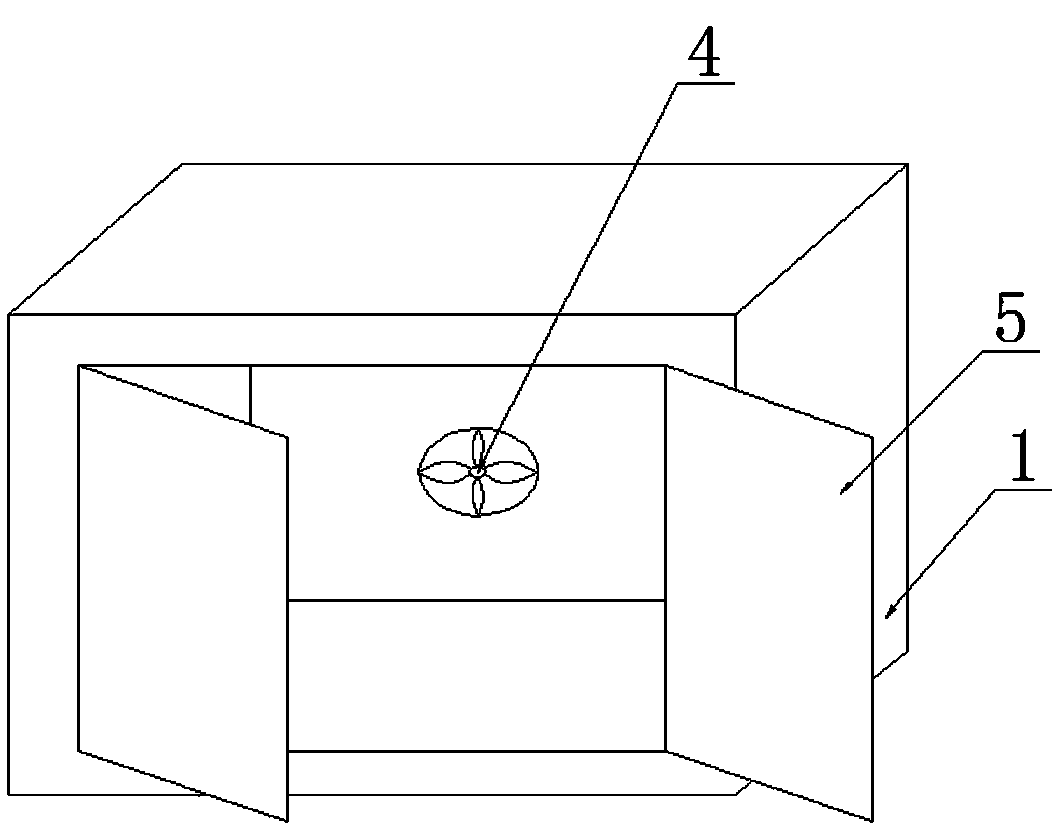

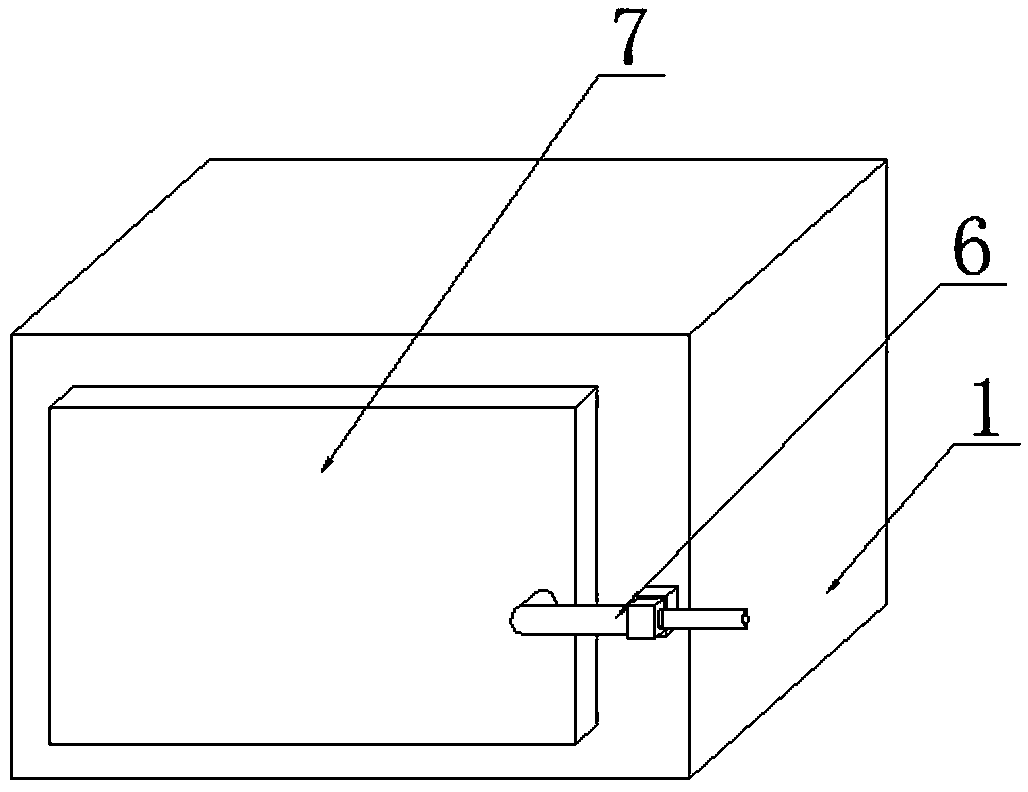

[0022] Figure 1-4 Shown is a box-type annealing furnace provided by the present invention, including: a box body 1, a tray 2, a bracket 3, a mounting frame, a heating layer, a sealing layer, a fan 4, an inner door 5, a main door lock 6, a box Door 7, handle 61, second rotating piece 62, U-shaped piece 63, fixed block 64, first rotating piece 65, threaded rod 66, nut 67, fixed rod 68 and connecting piece 69. The box body 1 is provided with a mounting frame, the mounting frame is provided with a multi-layer bracket 3, the bracket 3 is provided with a tray 2, and the tray 2 is covered with through holes; the inner wall of the box body 1 is provided with a heating layer and the fan 4; the box body 1 is equipped with a box door 7, a sealing layer is provided on the side of the box door 7, and the box door 7 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com