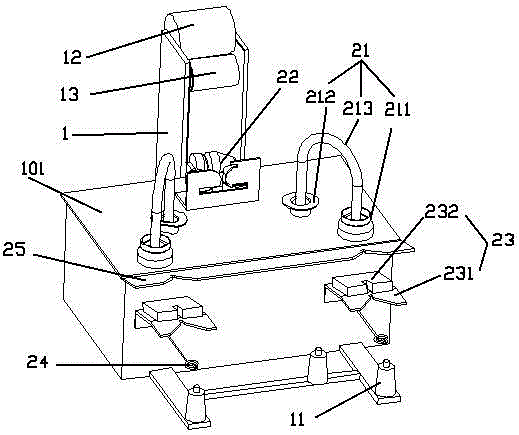

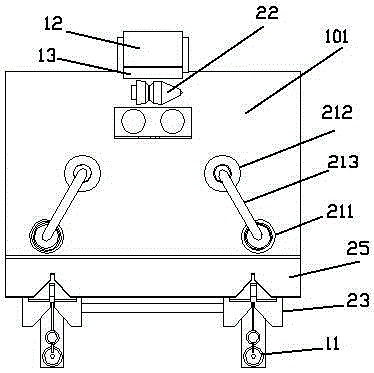

Wire structure of doubling machine

A doubling machine and thread structure technology, applied in textiles and papermaking, can solve the problems of easy mixing of yarns, inconvenient doubling, and poor doubling quality, and achieve smooth doubling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] as attached figure 1 , 2 The wire structure of a paralleling machine shown includes multiple paralleling units, and the number of paralleling units depends on the size of the factory building and the scale of the enterprise. The doubling unit includes a support frame 1, on which at least two pay-off bobbin placement parts 11 and a take-up bobbin placement part 12 are arranged, and the take-up bobbin placement parts 12 of adjacent doubling units are provided with Partition board, depending on the production needs, if two strands need to be merged into one strand, then two pay-off barrel placement parts 11 can be set, and if three strands or more than three strands need to be merged into one strand, three or more strands need to be set , this embodiment sets two. A take-up roller 13 is provided on one side of the take-up spool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com