A comprehensive operation parameter acquisition system of a dynamic compaction machine and its working method

A technology of operation parameters and collection system, which is applied in the direction of infrastructure engineering, construction, soil protection, etc., can solve the problems of difficult to effectively supervise the quality of the project, falsification of monitoring data, and construction personnel's leakage of tamping, etc., to save manpower and improve accuracy High, the effect of preventing stealing ramming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0058] It should be understood that this application mainly relates to the improvement of the overall structure of the comprehensive operation parameter acquisition system of the dynamic compaction machine. The GPS position information acquisition module 3, touch screen display 4, timer 6, memory 7 and trigger 1 involved in this application, Under the condition that the corresponding reliability of the system is satisfied, those skilled in the art should know its connection mode. In this application, the brief description of its working mode can be easily realized by those skilled in the art according to the relevant technology in this field.

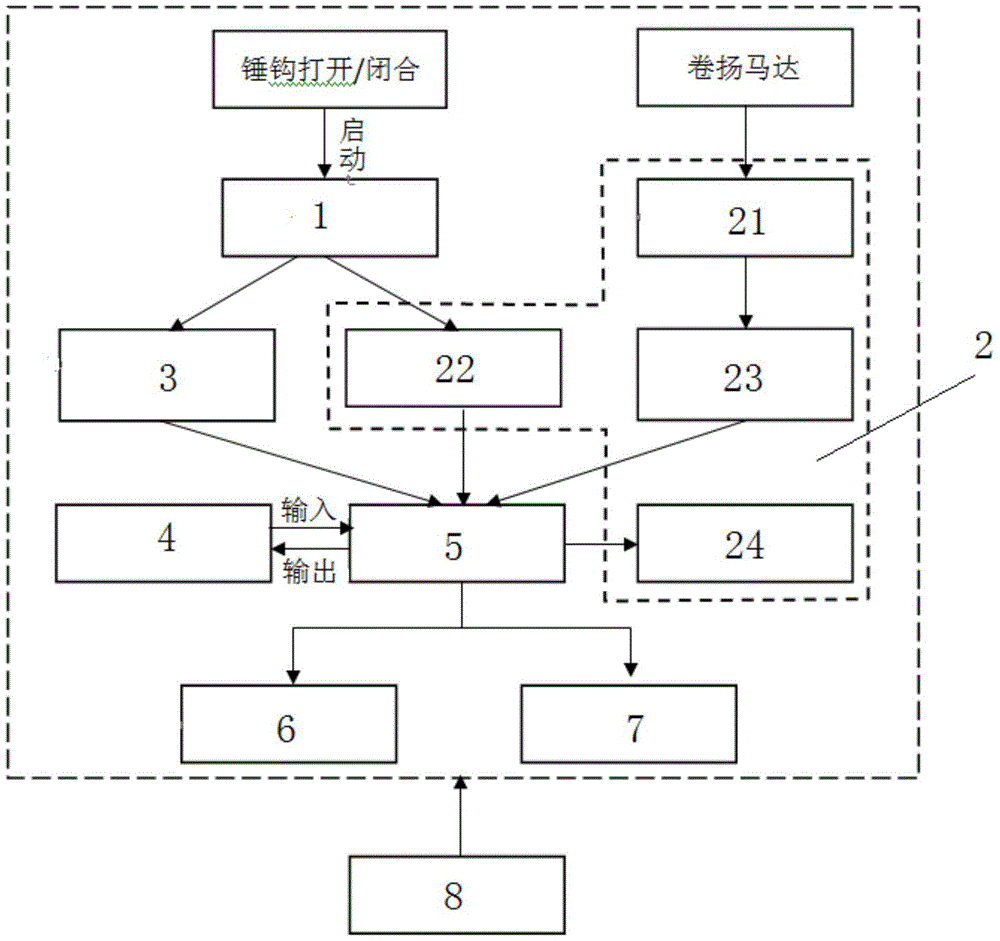

[0059] Such as figure 1 As shown, a dynamic compaction machine comprehensive operation parameter collection system, the system is based on the dynamic compaction machine, including trigger 1, dynamic compaction machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com