Multi-stage high-speed centrifugal type vapor compressor

A steam compressor and high-speed centrifugal technology, applied in mechanical equipment, non-displacement pumps, non-variable-capacity pumps, etc., can solve the problem that steam compressors cannot be multi-stage variable speed, and meet the requirements of multi-stage variable speed. The effect of reliable file and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of a multi-stage high-speed centrifugal steam compressor of the present invention will be described in detail below in conjunction with the accompanying drawings.

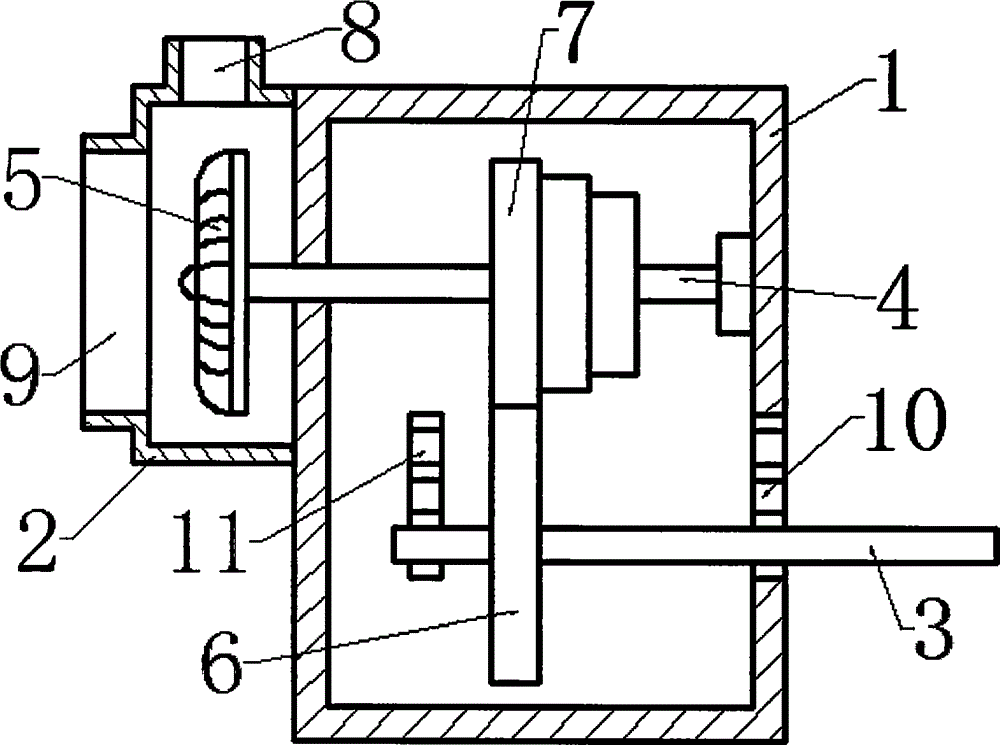

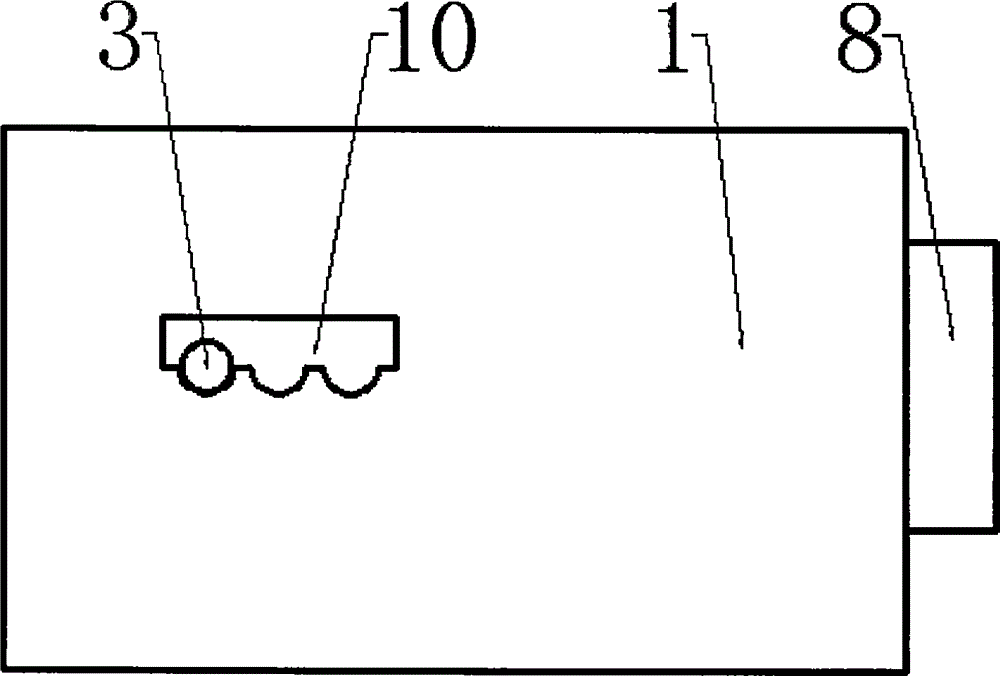

[0017] combine figure 1 and figure 2 Describe the specific embodiment of a kind of multi-stage high-speed centrifugal steam compressor of the present invention, this multi-stage high-speed centrifugal steam compressor comprises a box-shaped gear box 1, and the side of gear box 1 box body is provided with shift hole 10, The inside of the gear box 1 is provided with a shift support frame 11 corresponding to the shift hole 10, and a drive shaft 3 is arranged between the shift hole 10 and the shift support frame 11, and the drive shaft 3 passes through the shift hole 10 and is connected to the motor. A driving gear 6 is fixed on the driving shaft 3, and a driven shaft 4 is also fixed inside the gearbox 1, the driven shaft 4 and the driving shaft 3 are parallel to each other, and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com