Leakage detection device for two-layer vacuum soft bags

A double-layer vacuum and leak detection technology, which is applied in the direction of using liquid/vacuum to measure liquid tightness and detecting the appearance of fluid at the leakage point, can solve the problems of negative leakage and unsuitable double-layer vacuum soft bags, etc. To achieve the effect of accurate pressure, preventing movement and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

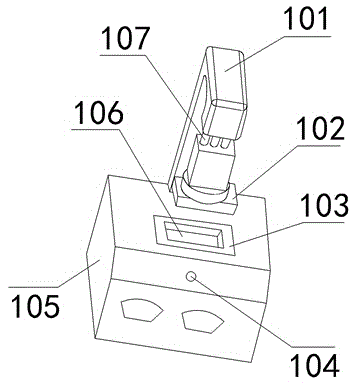

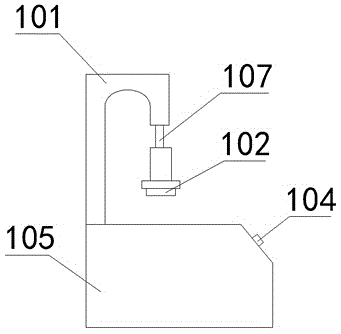

[0030] Such as figure 1 , figure 2 As shown, the present embodiment provides a leak detection device for a double-layer vacuum soft bag, which includes: a frame 101, a drive rod 107, a cylinder and a leak detection mold; the cylinder is arranged on the frame 101, and the drive rod 107 It is connected with the cylinder; the control switch 104 of the cylinder is arranged on the panel of the frame 101 .

[0031] The leak detection mold includes a leak detection punch 102 and a leak detection die 103 that match each other, the leak detection die 103 is provided with a groove 106 for placing a double-layer vacuum soft bag, and the leak detection punch 102 matches the groove 106 The leak detection punch 102 is connected with the telescopic rod, and the leak detection die 103 is fixedly arranged on the frame 101 and is located below the leak detection punch 102 ;

[0032] The frame 101 is provided with a base 105, which facilitates the placement of the leak detection device, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com