Method for carrying out finite element analysis on vehicle-mounted cabinet body

A vehicle-mounted cabinet and finite element technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of slowing down the design progress of the vehicle-mounted cabinet, low efficiency, etc., to reduce the occupation of computer resources, Effects of improving efficiency and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

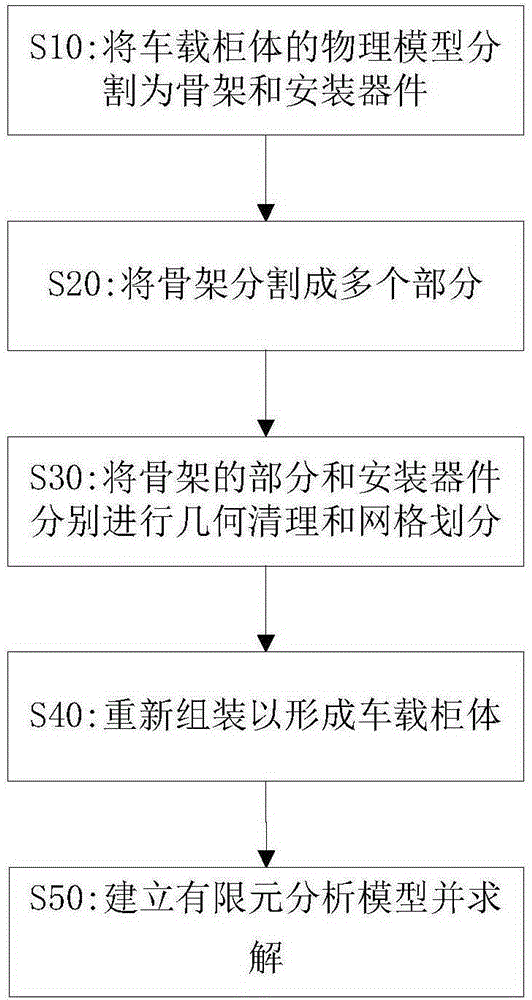

[0021] figure 1 It shows the flow of the method for performing finite element analysis on the vehicle-mounted cabinet in the embodiment. In this embodiment, this method is implemented based on HyperMesh. The method for carrying out finite element analysis on the vehicle-mounted cabinet comprises the following steps:

[0022] S10: In the physical model of the vehicle-mounted cabinet, separate the skeleton and installation devices that are only connected with each other by bolts.

[0023] Vehicle cabinets usually include framework, bolts, mounting hardware and door assemblies. The skeleton plays a supporting role in the vehicle cabinet. Bolts fix the mounting device on the frame. The skeleton is a box-shell structure, usually composed of sheet metal parts. The skeleton includes multiple beams, columns and box panels. Multiple beams and multiple columns are built into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com