Profile elements and profile element components for joining vehicle glazing to cover parts

A technology for covering components and vehicle glass, which is applied to vehicle components, engine components, engine sealing, etc., and can solve problems such as detachment of contour units and damage of contour units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

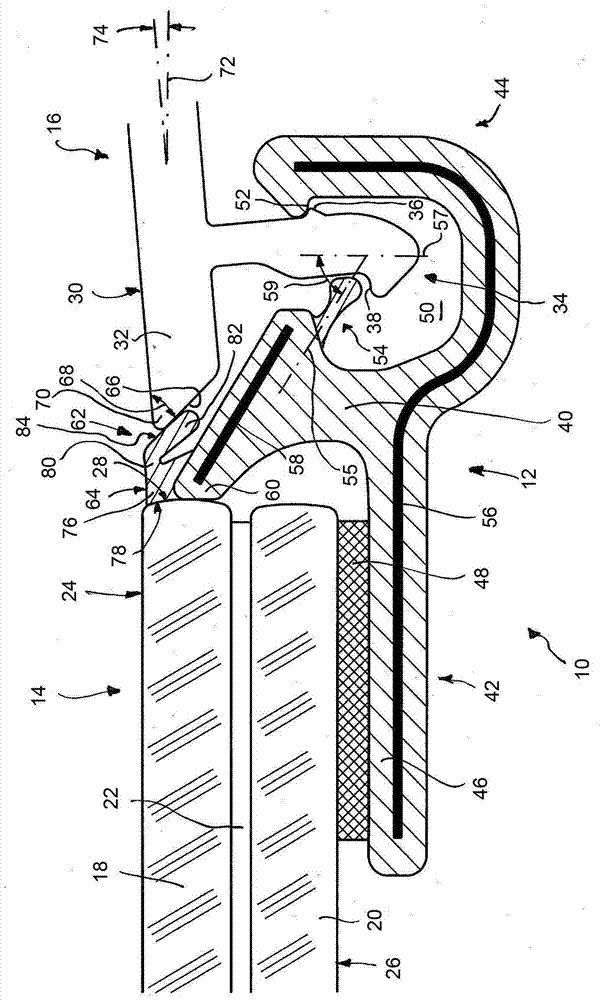

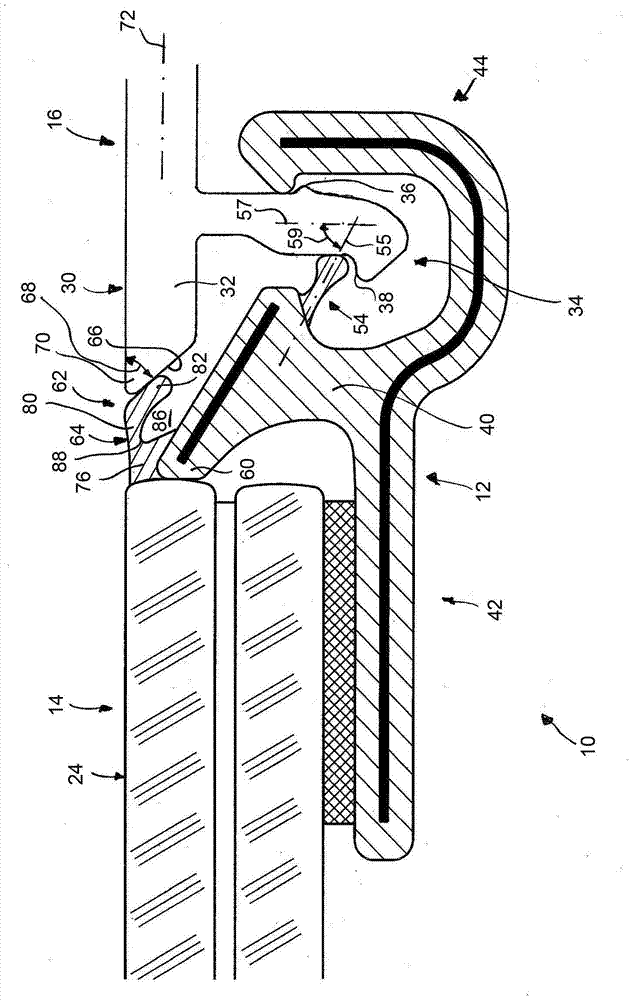

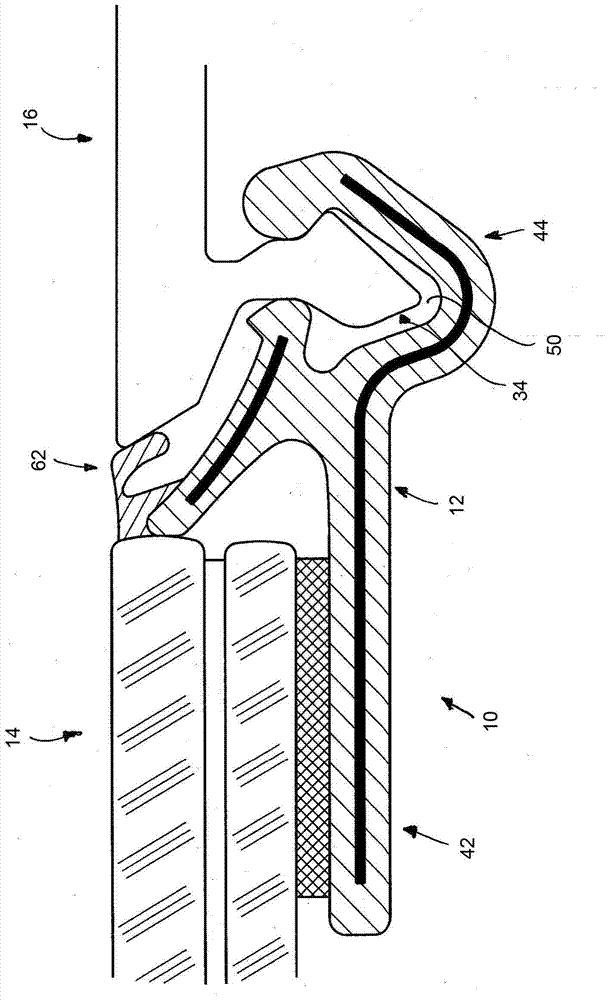

[0031] exist figure 1 An embodiment of a mid-profile unit assembly is shown generally at 10 . The assembly 10 comprises a profile unit 12 as well as a vehicle glass 14 (in particular a front windshield of the vehicle), only partially shown, and a cover part 16 , which is only partially shown, which is designed in particular as a radiator cap. Therefore, hereinafter, the cover part 16 is described as the water tank cover 16 .

[0032] Advantageously, the vehicle glazing 14 is a composite structure comprising mutually parallel glass layers 18 and 20 which are connected to one another by means of a connecting layer 22 . The vehicle glass 14 includes an outer side 24 , an inner side 26 , and a front face 28 extending along an edge of the vehicle glass 14 between the outer side 24 and the inner side 26 .

[0033] The radiator cover 16 has an outer side 30 which, in the installed state of the radiator cover 16 (see figure 2 ) are arranged at least substantially at the same heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com