Gear-system arrangement for driving a vacuum roll and for supporting the internal structures of a vacuum roll

A technology of gear system and internal structure, applied in shafts and bearings, textiles and papermaking, papermaking, etc., can solve problems such as complex structure of gear system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

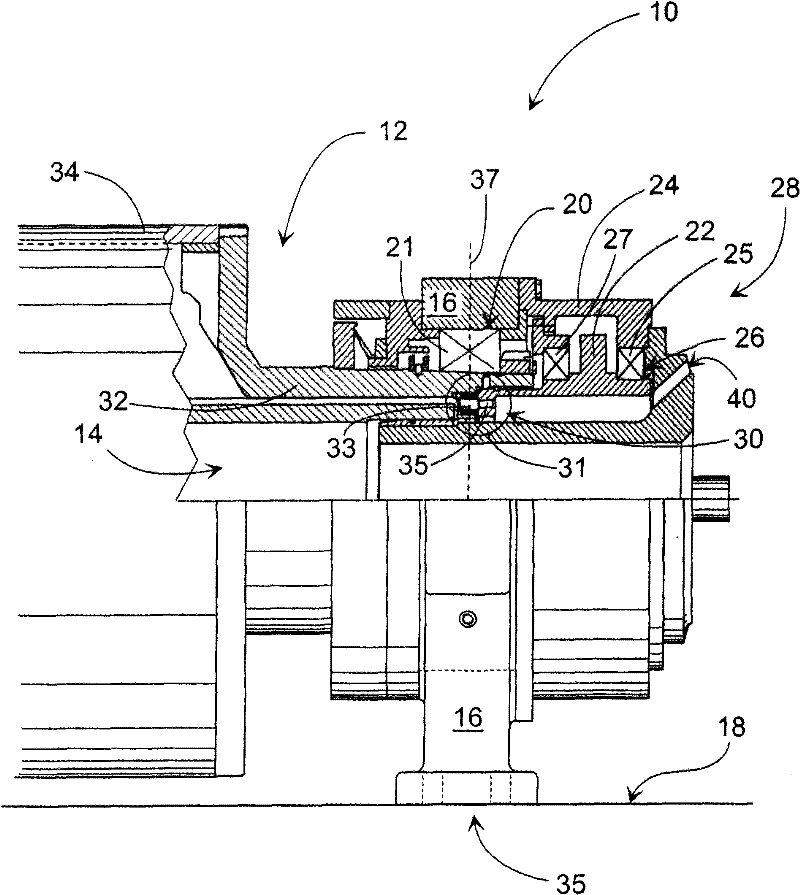

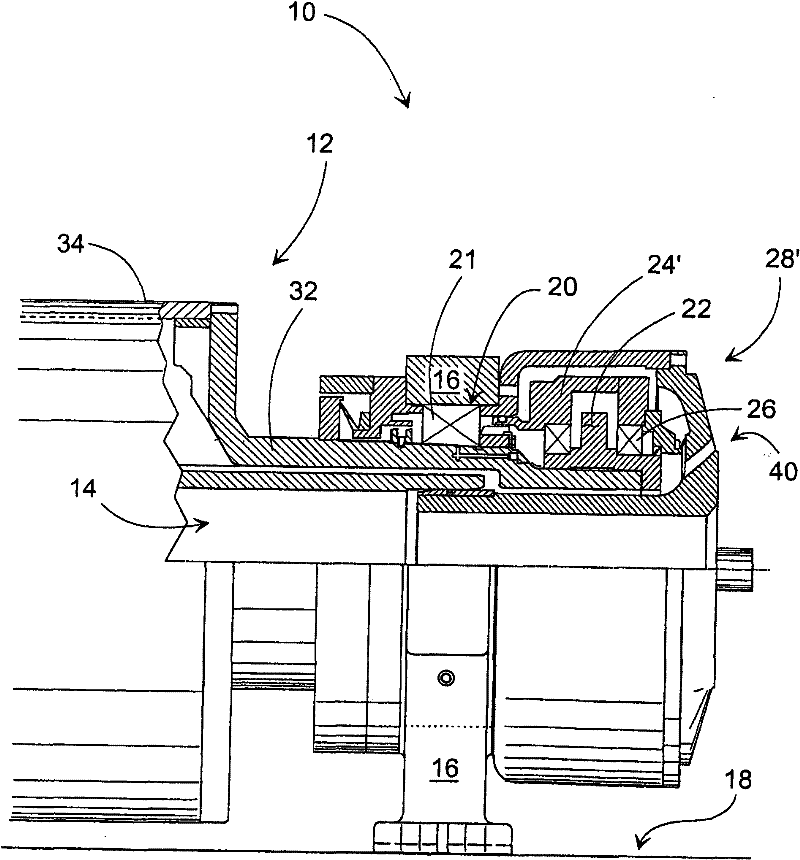

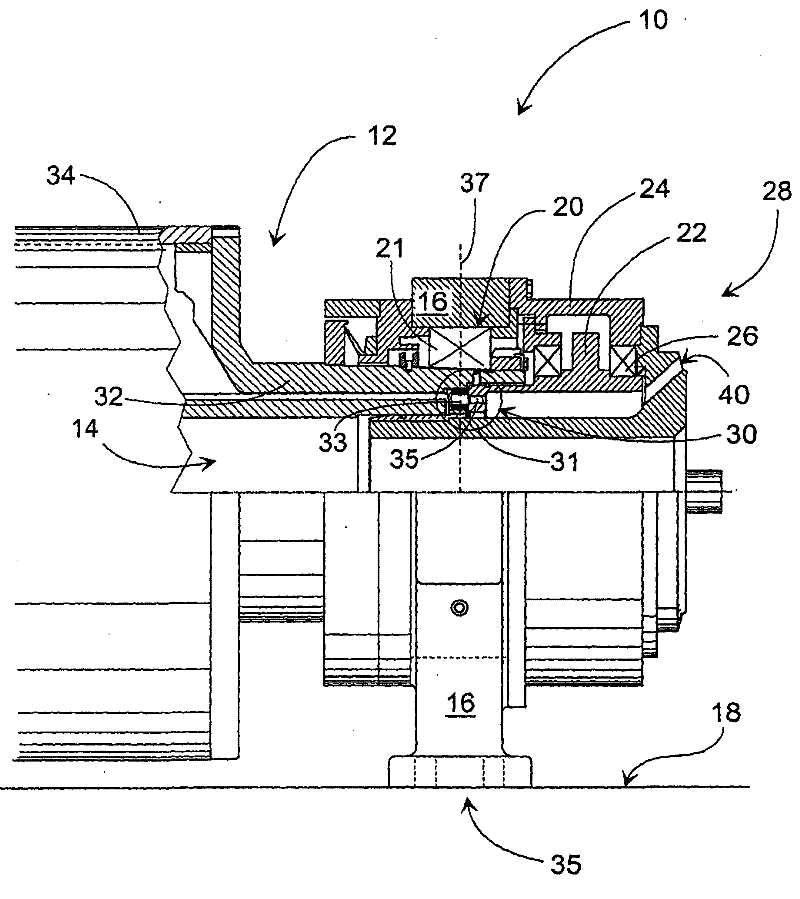

[0020] figure 1 A gear system configuration 10 according to the prior art is shown on a foundation 18 . The gear system configuration 10 includes a frame 16 to which the vacuum roll 12 is connected by a carrier bearing assembly 20 . The carrier bearing assembly 20 is attached to the interior of the frame 16 such that the vacuum roll 12 is supported on the frame 16 from its flanged shaft 32 through the carrier bearing assembly 20 . The structure 14 inside the vacuum roll is supported by a carrier ring 28 ′ which is connected to the frame 16 . Vent holes 40 are provided in the carrier ring 28'. The vacuum roll 12 includes a flanged shaft 32 and a housing 34 . A gear 22 for driving the vacuum roll 12 is connected to the vacuum roll 12, more particularly to a flanged shaft 32 of the vacuum roll. The vacuum connection of the vacuum roll is connected to the carrier ring or to the inner structure of the vacuum roll carried by it. The gearbox 24' is located inside the carrier rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com