Ultrasonic transducer and ultrasonic flow meter

An ultrasonic transducer and ultrasonic signal technology, applied in the directions of sound-producing equipment, flow/mass flow measurement, liquid/fluid solid measurement, etc., can solve problems such as measurement errors and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

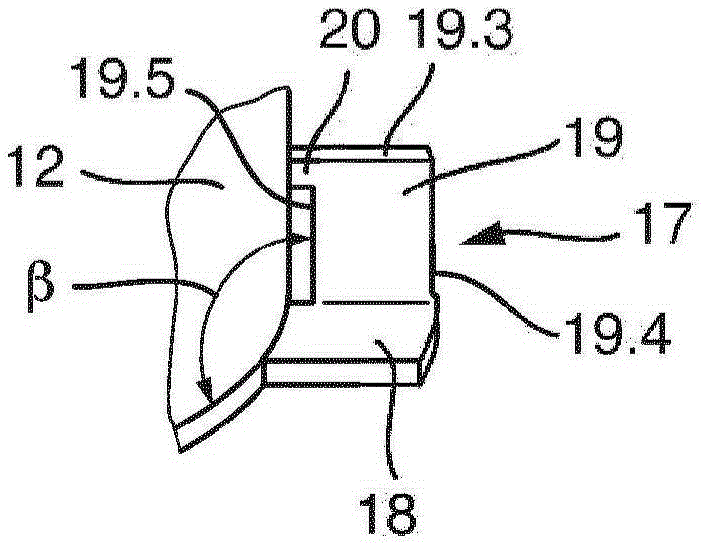

[0037] Figure 6 There is shown an ultrasound transducer 1 generally known and described in EP0974814B1, the disclosure of which is fully incorporated herein by reference.

[0038] The ultrasonic transducer 1 has an arrangement of a piezoelectric element 2 and a metal disk 4 . The ultrasound transducer also has a coupling element 3 . This coupling element 3 is also often referred to as a coupling body. Coupling elements are often designed as wedges and are therefore called coupling wedges by experts.

[0039] In the exemplary embodiment the coupling element is also designed as a coupling wedge. In the following, the form and function of the coupling element will be explained in detail.

[0040] The basic shape of the coupling element is cylindrical with a shell surface and two bottom surfaces. One of the two bottom surfaces is angled.

[0041] Compared to known coupling elements, the inventive coupling element has an oblique bore-shaped special recess 5 in which the piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com