A granary with a rotating silo structure

A rotary and warehouse technology, which is applied in agricultural machinery and implements, fruit hanging devices, botanical equipment and methods, etc., can solve the problems that cannot meet the needs of large grain growers, scientific grain storage warehouses have small capacity, and affect the income of grain growing. To achieve the effect of solving the problem of pest and rodent damage, maintaining stable grain temperature and avoiding the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings.

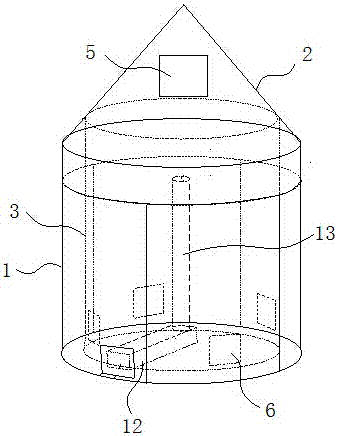

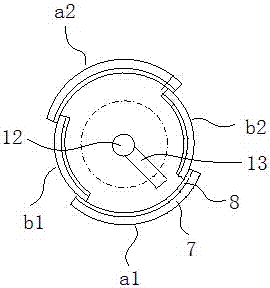

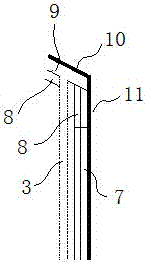

[0023] Such as figure 1 , figure 2 and image 3 As shown, a granary with a rotating silo structure includes a silo body 1 and a silo roof 2 connected as a whole, and a waterproof layer 10 and a thermal insulation coating layer 11 are provided outside the silo body 1 and the silo roof 2 . The warehouse body 1 is composed of an inner wall 3 and an outer wall 4; the inner wall 3 is a mesh inner wall, which can be galvanized steel mesh; there is a gap between the inner wall 3 and the outer wall 4, and the gap is filled with air to form an air insulation layer; the outer wall 4 It is a rotating waterproof and heat-insulating layer, which is composed of several parts connected in sequence, and the parts can be pushed and pulled to move each other; the rotating waterproof and heat-insulating layer is preferably composed of four parts, namely the first part a1, the second part b1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com