Automatic slicer

An automatic and transmission control unit technology, applied in the fields of food forming, food science, application, etc., can solve the problems of no large-scale mass production, simple and backward paving equipment, difficult to connect production lines, etc., to achieve good paving effect, The effect of reducing labor costs and preventing splashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

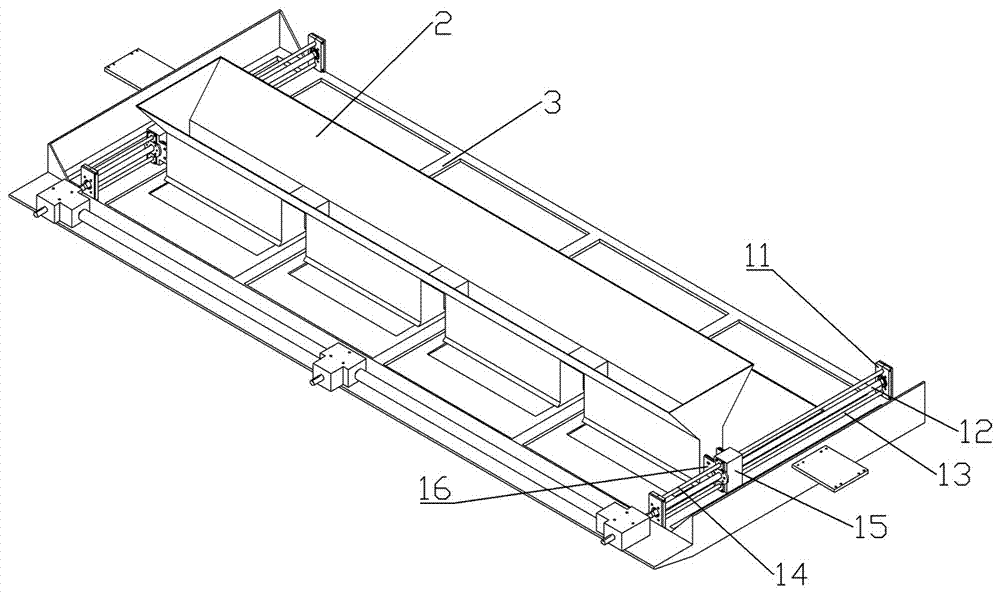

[0029] Embodiment one, see figure 1 As shown, an automatic spreading machine includes a support base, a transmission control unit and a paving mechanism. The support base is fixed on both sides of the production line frame. The paving mechanism is connected to the transmission control unit through a slider. The platform phase signal connection, the paving mechanism includes the main feeding bin, several branch feeding bins and the outlets corresponding to the branch feeding bins, the transmission control unit includes the support frame and the precision control mechanism respectively arranged at both ends of the support frame , the precision control mechanism includes a commutator, an optical shaft, a ball screw and a slider, the two ends of the optical shaft and the ball screw are fixed by a bearing seat and a support frame, and one end of the ball screw extends out of the support frame and the commutator There are two optical axes, symmetrically arranged on both sides of the...

Embodiment 2

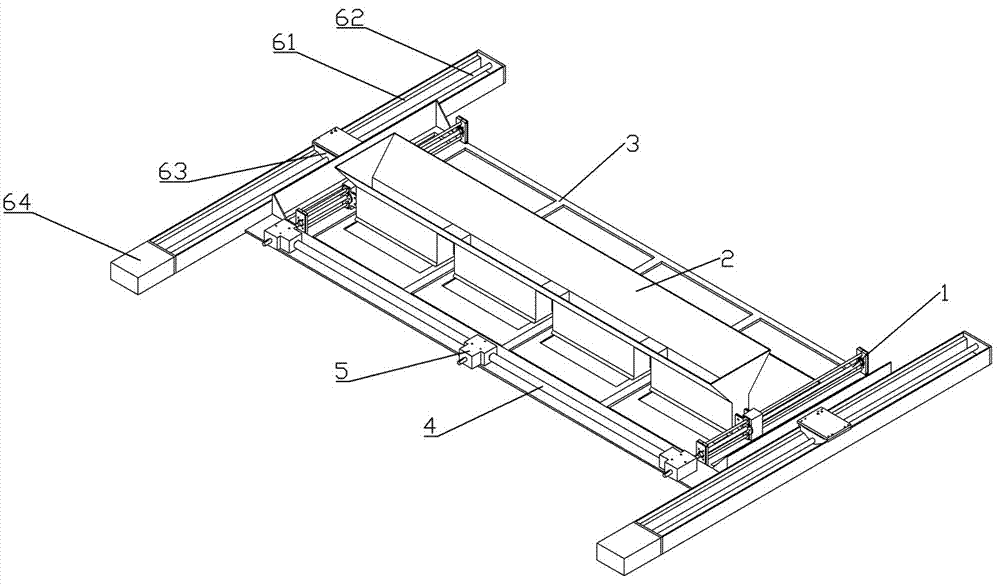

[0031] Embodiment two, see Figure 2~4 As shown, it is basically the same as Embodiment 1, the difference is that the support seat includes the support seat body, the slide rail set in the support seat body, the ball screw rod two set in the slide rail and the slider matching the slide rail 2. The two ends of the ball screw two are respectively fixed to the main body of the support seat, the second slider is put on the second ball screw, and one end of the main body of the support seat is also provided with a synchronous servo motor connected with the signal of the assembly line console, and the support frame passes through The connecting plate and the slider two are fixed to realize synchronous operation with the production line of jujube slices, realize docking with the production line of jujube slices, greatly reduce the cost of manual work, and effectively improve the automation of the production line.

Embodiment 3

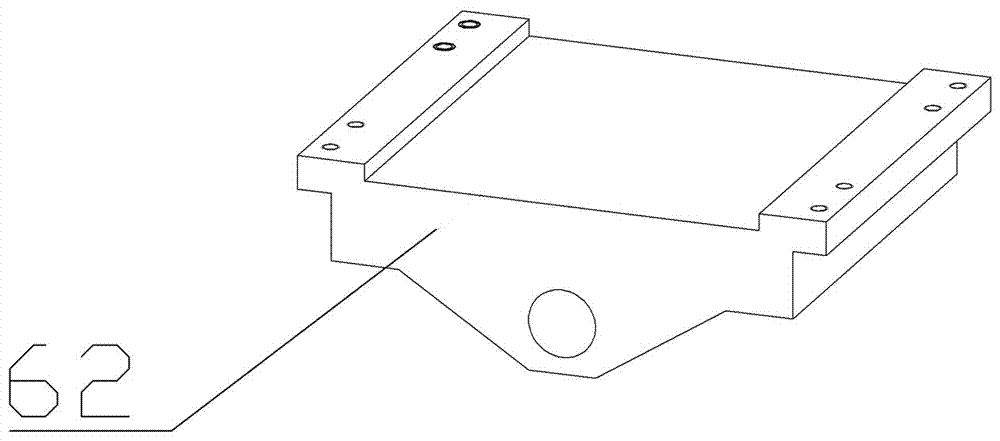

[0032] Embodiment three, see Figure 5~6 As shown, it is basically the same as Embodiment 1, except that the support frame includes a support frame body, vertical baffles arranged at both ends of the support frame body, and a precision control mechanism support arranged on the support frame body, supporting A fixed plate for installing the commutator is extended on one side of the frame body, and a mounting plate body is fixed on the outside of the vertical baffle, and the mounting plate body is fixed with the support seat, which is more convenient for disassembly, maintenance and installation.

[0033] Preferably, the support frame body is also provided with a number of precision control bins corresponding to the branch feeding bins, and a jujube paste scraping bin is arranged in the precision control bins.

[0034] As mentioned above, the commutator includes commutator 1 and the end commutators connected with the ball screw respectively, the commutator 1 and the end commutat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com