Valve block cleaning rotating tower

A turret and valve block technology, applied in the field of saturated steam cleaning, can solve the problems of workpiece rust, incomplete cleaning, and high environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

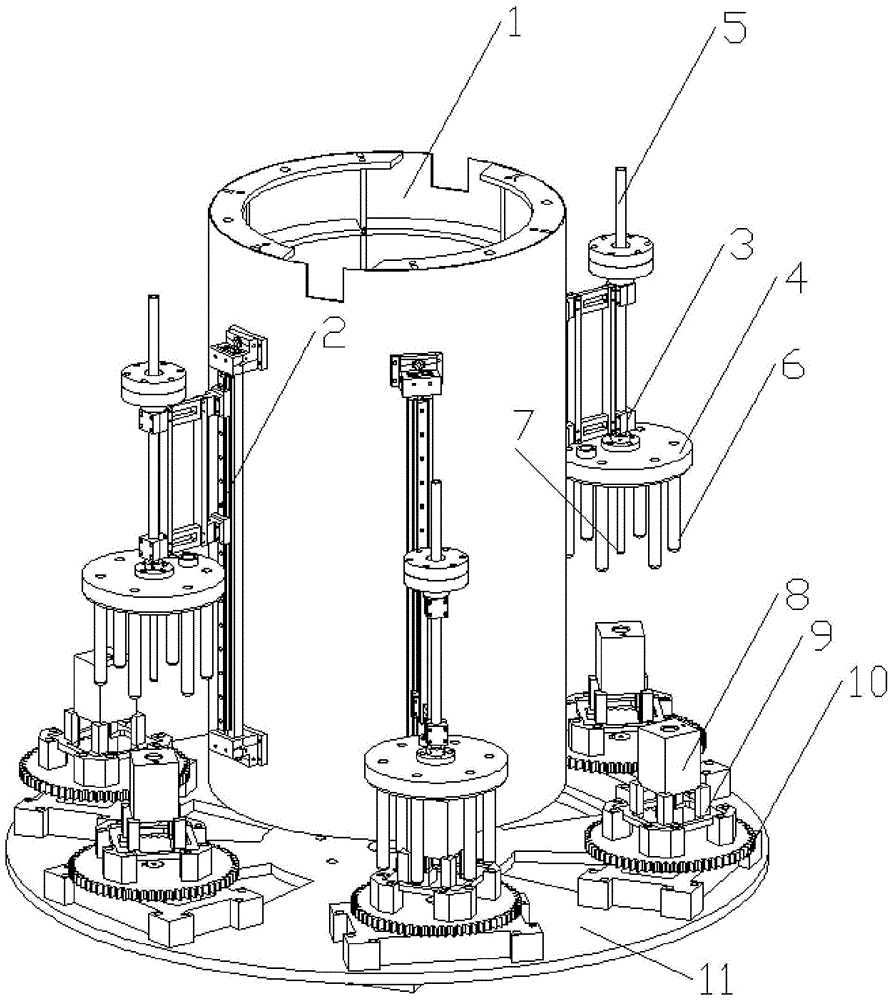

[0018] The present invention will be further described below in conjunction with accompanying drawing:

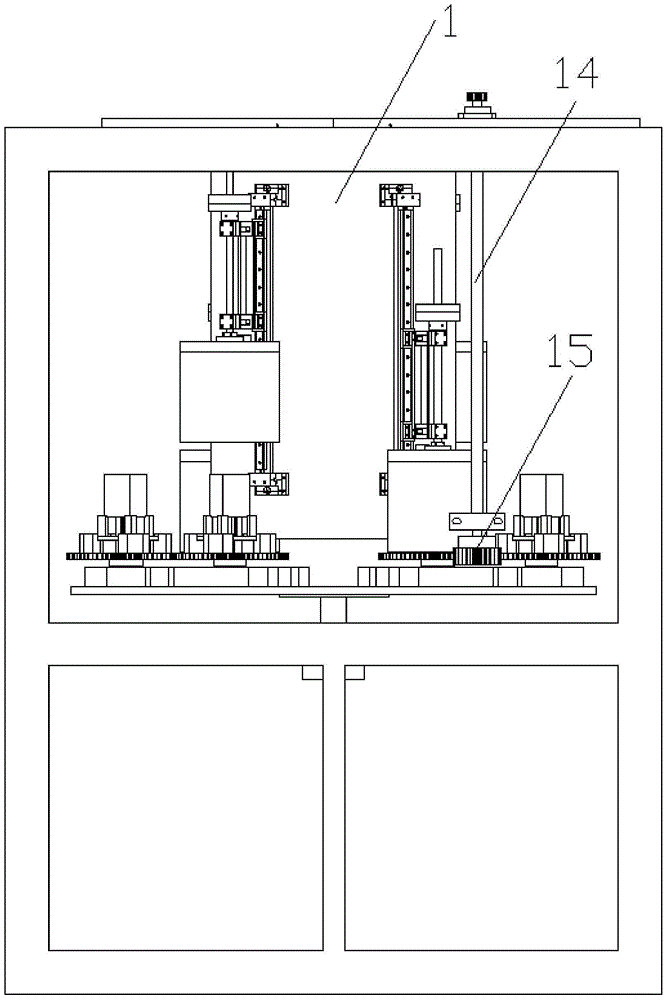

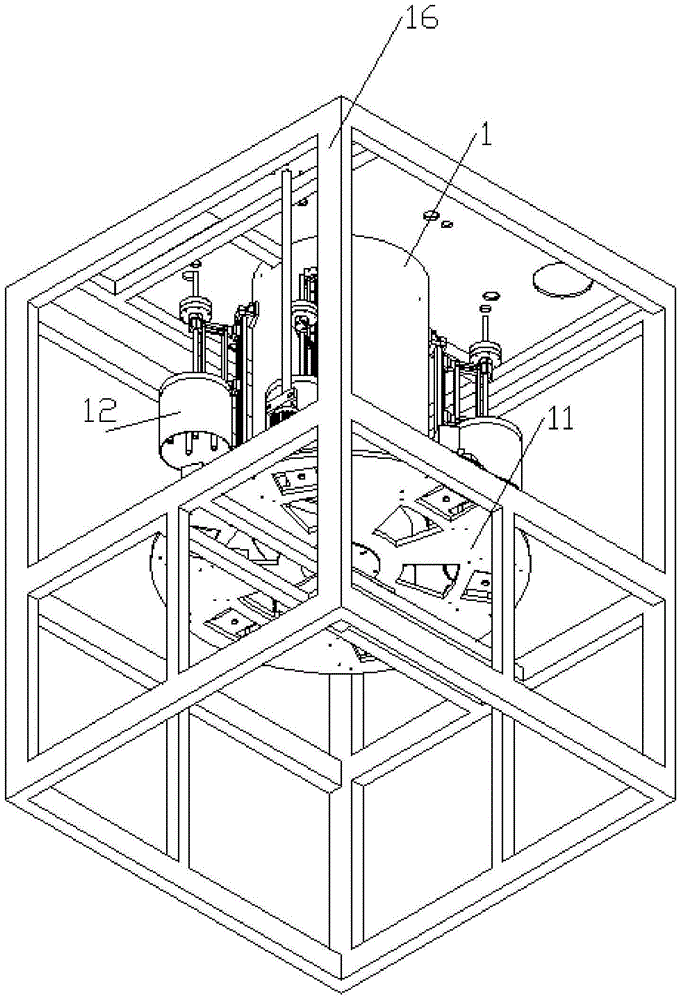

[0019] Such as Figure 1 to Figure 4 , a valve block cleaning turret, including a central cylinder 1, a lifting guide rail 2, a lifting frame 3, a lifting plate 4, a guide rod 5, an external steam pipe 6, an internally extending steam pipe 7, a workpiece 8, a tooling fixture 9, and a fixture gear The turntable 10 and the base 11, the center cylinder 1 is arranged in the center of the base 11, the base 11 is also provided with 6 fixture gear turntables 10 surrounding the center barrel 1, each fixture gear turntable 10 is provided with a tooling fixture 9, each The corresponding positions above the tooling fixture 9 are respectively provided with a lifting guide rail 2 corresponding to it one by one. The lifting guide rail 2 is fixed on the central cylinder 1, and each lifting guide rail 2 is movably connected to the lifting frame 3 respectively, and the lifting frame 3 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com