A kind of lead parts casting equipment

A technology of lead parts and equipment, which is applied in the field of lead parts casting equipment, can solve the problems of poor adaptability of lead parts molds, low production efficiency, and low degree of automation, and achieve the effects of improving production efficiency, reliable blanking, and improving connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

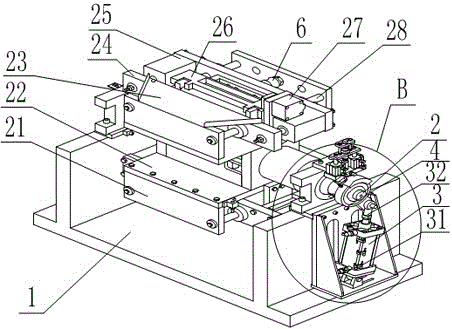

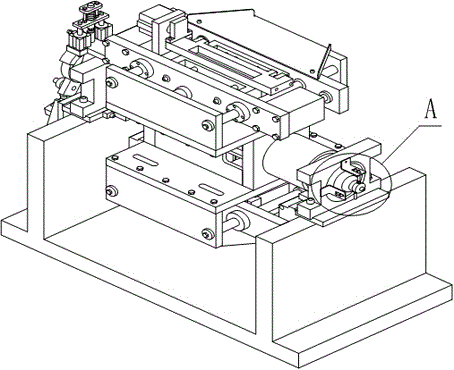

[0033] Such as figure 1 , figure 2 , Figure 5 , Figure 7 As shown, a lead parts casting equipment is characterized in that it includes a frame 1, a mold frame shaft 2 is arranged on the frame 1, and two sets of mold frames that are rotationally symmetrical along the mold frame shaft 2, and the mold frame shaft 2 is in the During work, one-way rotation is performed at a rotation angle of 90° / time. The middle part of the mold base shaft 2 is provided with a jacking cylinder 9, and the mold base shaft 2 is equipped with a one-way driving mechanism. 2 Connected formwork base plate 22, formwork base plate 22 is vertically provided with formwork guide post seat 21, and the upper end of formwork base plate 22 is symmetrically provided with two mold fixing plates 24 parallel to formwork guide post seat 21, one of the mold The upper end of the fixed plate 24 is provided with a waste sloping plate 23, and the two ends between the two mold fixed plates 24 are provided with a mold o...

Embodiment 2

[0035] Such as figure 1 , figure 2 , Figure 5 As shown, this embodiment is based on Embodiment 1, the joint bearing 32 is arranged in the axial direction of the cylinder I3, and the connection between the joint bearing 32 and the overrunning clutch 4 forms an included angle smaller than 180 degrees.

Embodiment 3

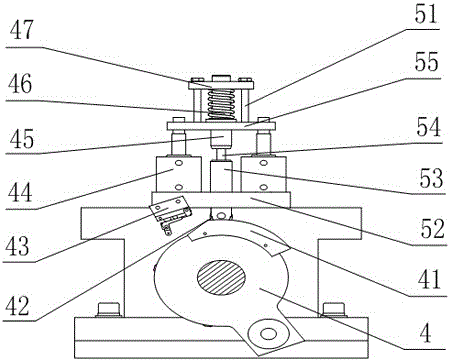

[0037] Such as Figure 1 to Figure 7 As shown, this embodiment is based on Embodiment 1 or Embodiment 2. The positioning mechanism includes a cylinder base 52 arranged on the bearing seat, two cylinders 44 are symmetrically arranged on the cylinder base 52, and the output ends of the cylinders 44 are provided with connections Plate 55, the center of connecting plate 55 is provided with spring mandrel 45, and spring mandrel 45 upper ends are provided with spring pressing plate 47, and spring mandrel 47 is sleeved with spring 46 between connecting plate 55 and spring pressing plate 47, and spring core The lower end of the shaft 47 is connected with a roller shaft 53 through a connecting screw rod 54. The movable end of the roller shaft 53 is provided with a roller 42. 4 equally divided star wheel-shaped parts on the side; the two ends of the spring pressing plate 47 are provided with bolts 51 to connect, and the bolts 51 pass through the through holes on the spring pressing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com