Hand lay-up molding method

A technology of hand lay-up molding and base layer, which is applied in the field of composite material molding, and can solve the problems of low quality of hand lay-up technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

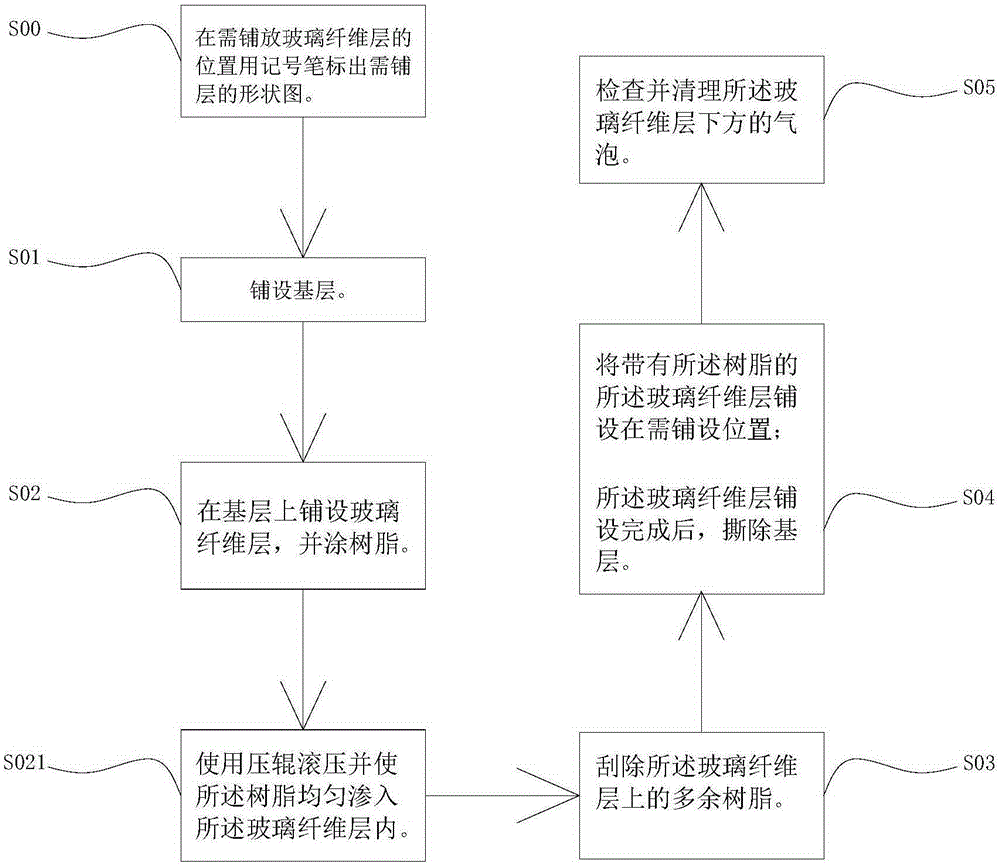

[0017] The hand lay-up molding method of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0018] Such as figure 1 As shown, in this embodiment, the hand lay-up method includes the following steps: step S01: laying the base layer, and then proceed to step S02: laying a glass fiber cloth layer on the base layer, and rolling coating on the aforementioned glass fiber cloth layer Mix the resin evenly to make the resin evenly infiltrate into the glass fiber cloth layer, and then proceed to step S03: scrape off the excess resin after step S02 (the excess resin here refers to the resin attached to the glass fiber cloth layer beyond the designed amount) , followed by step S04: Lay the glass fiber cloth layer in step S03 to the position where hand lay-up is required, and compact it, and finally tear off the base layer. In this process, since the base layer is set, the glass fiber cloth layer is laid on the base lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com