Patents

Literature

43results about How to "Avoid affecting intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

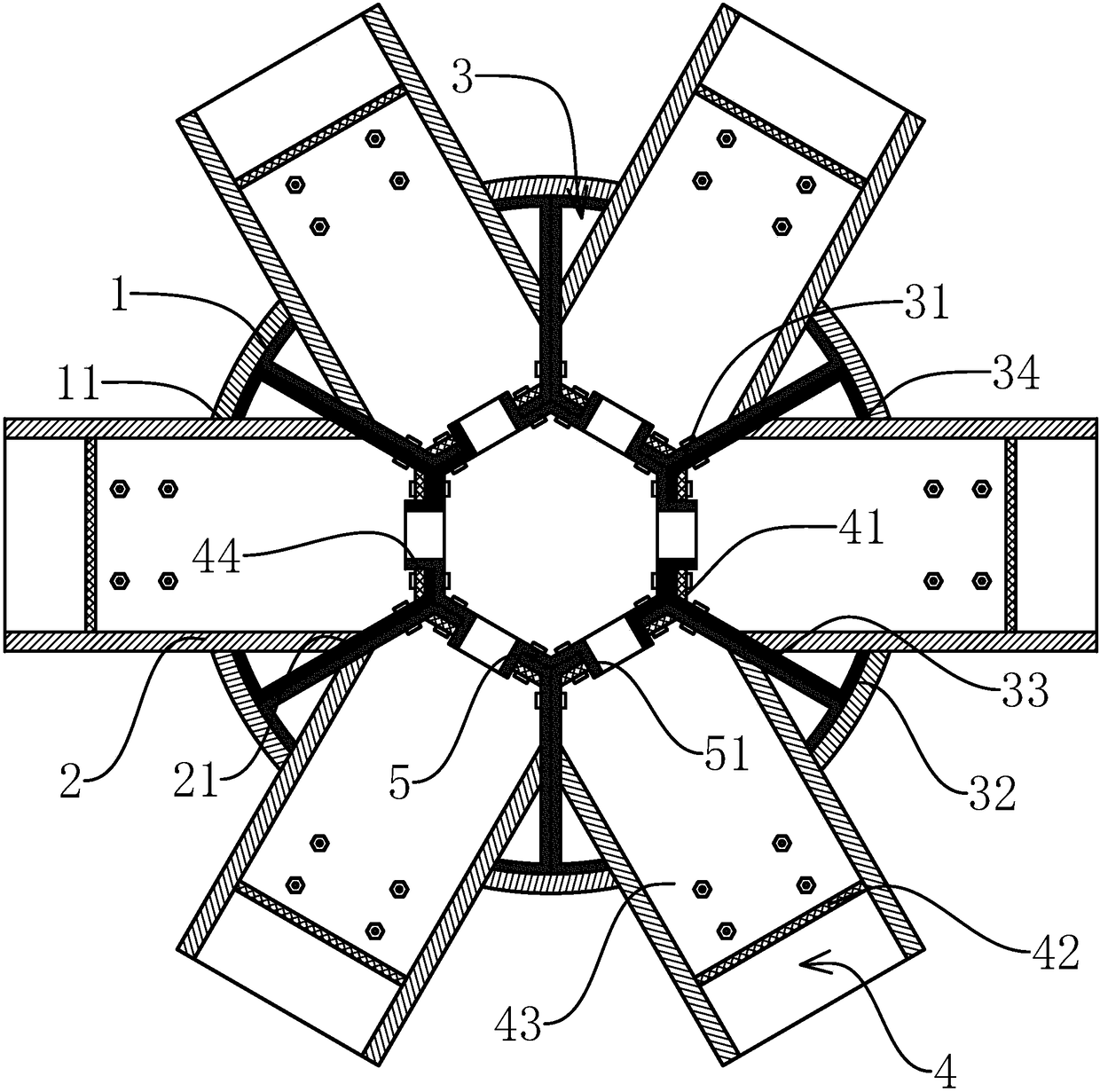

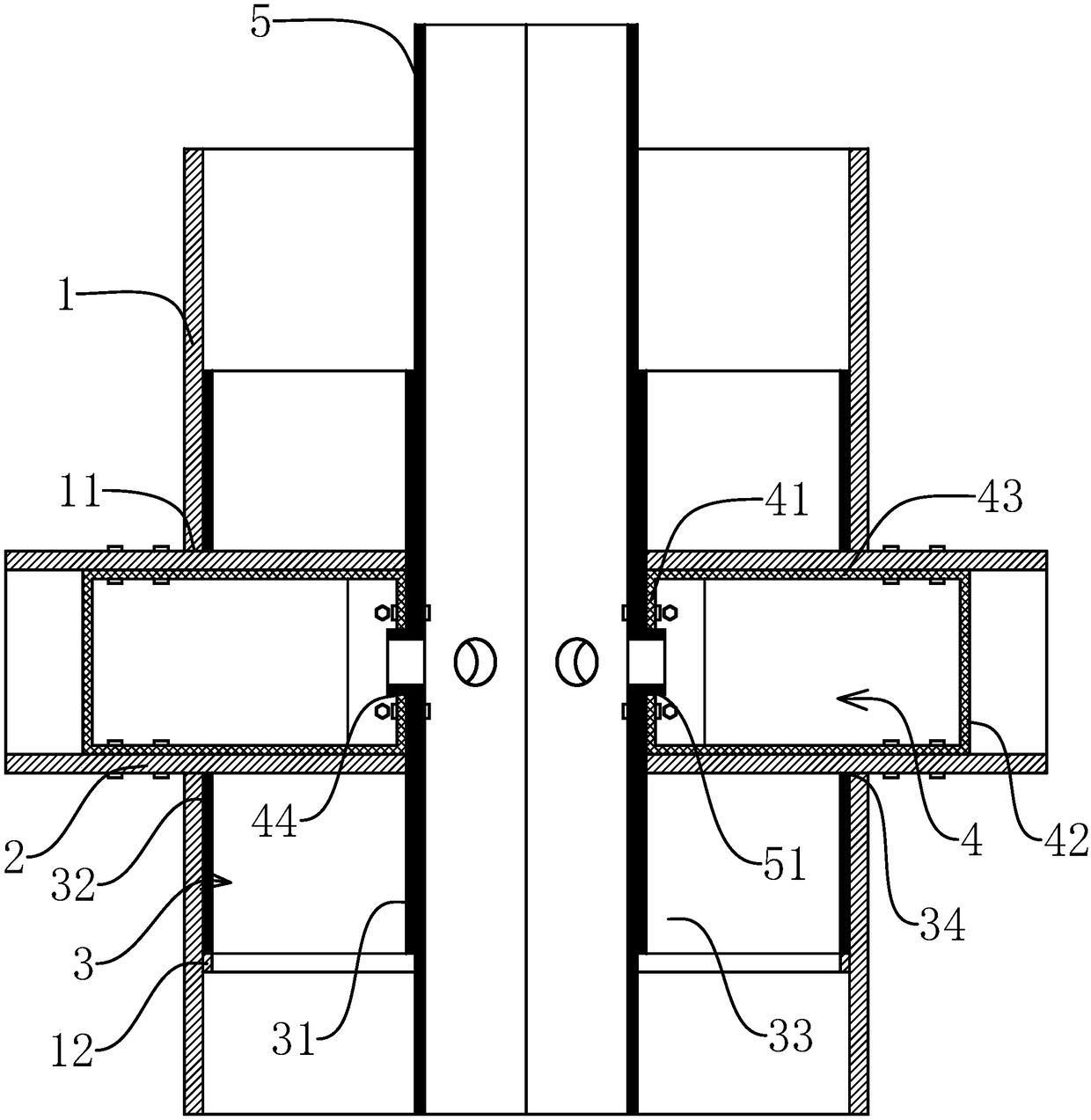

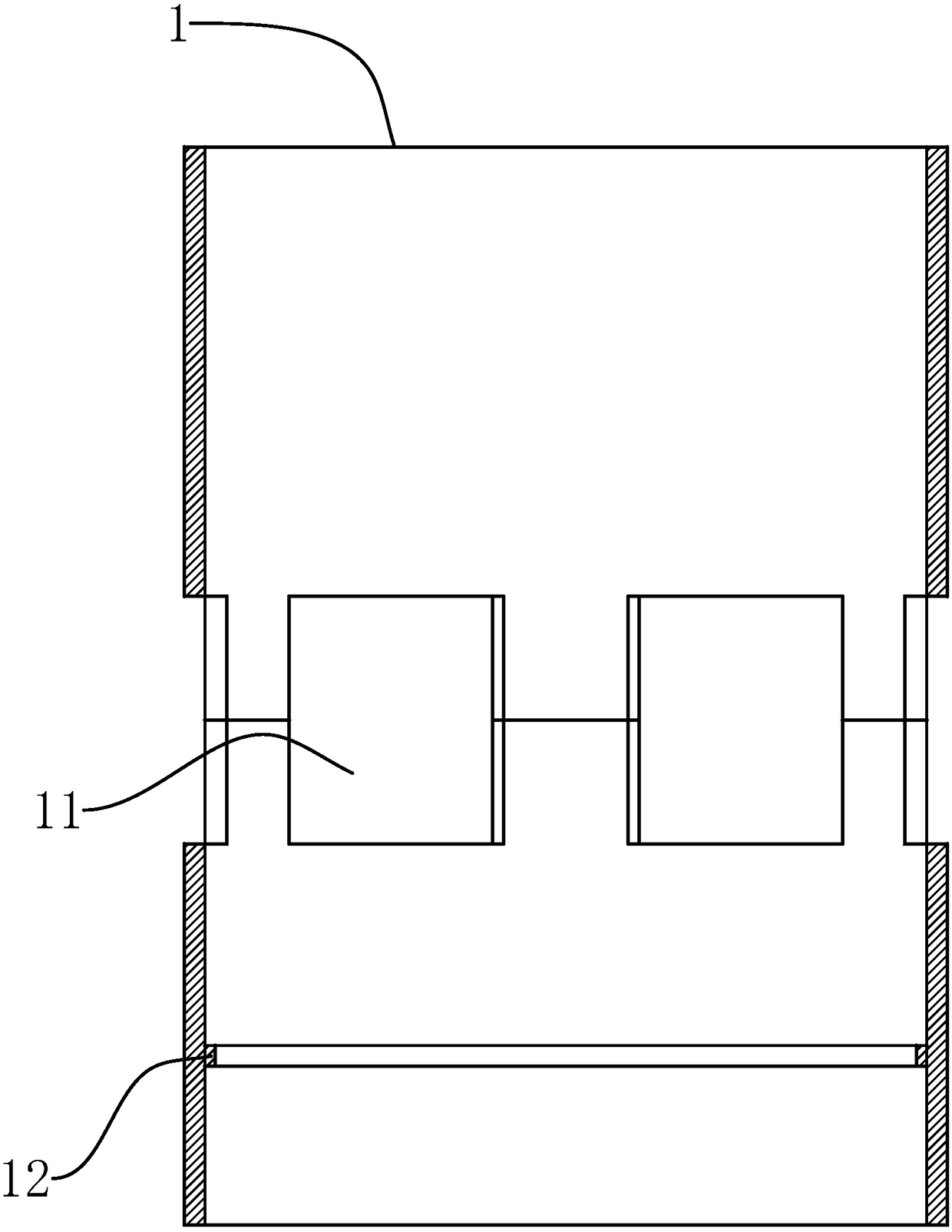

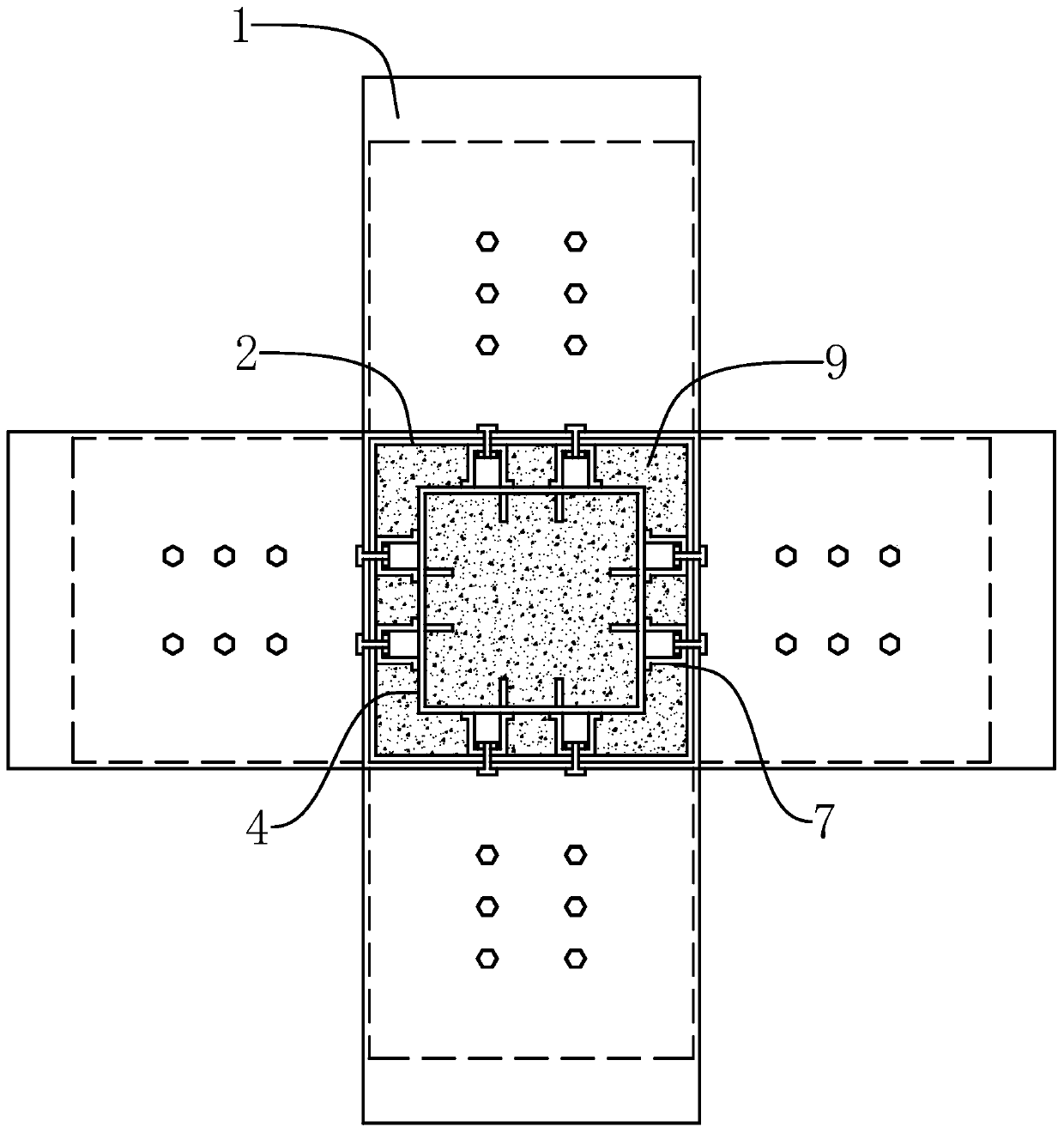

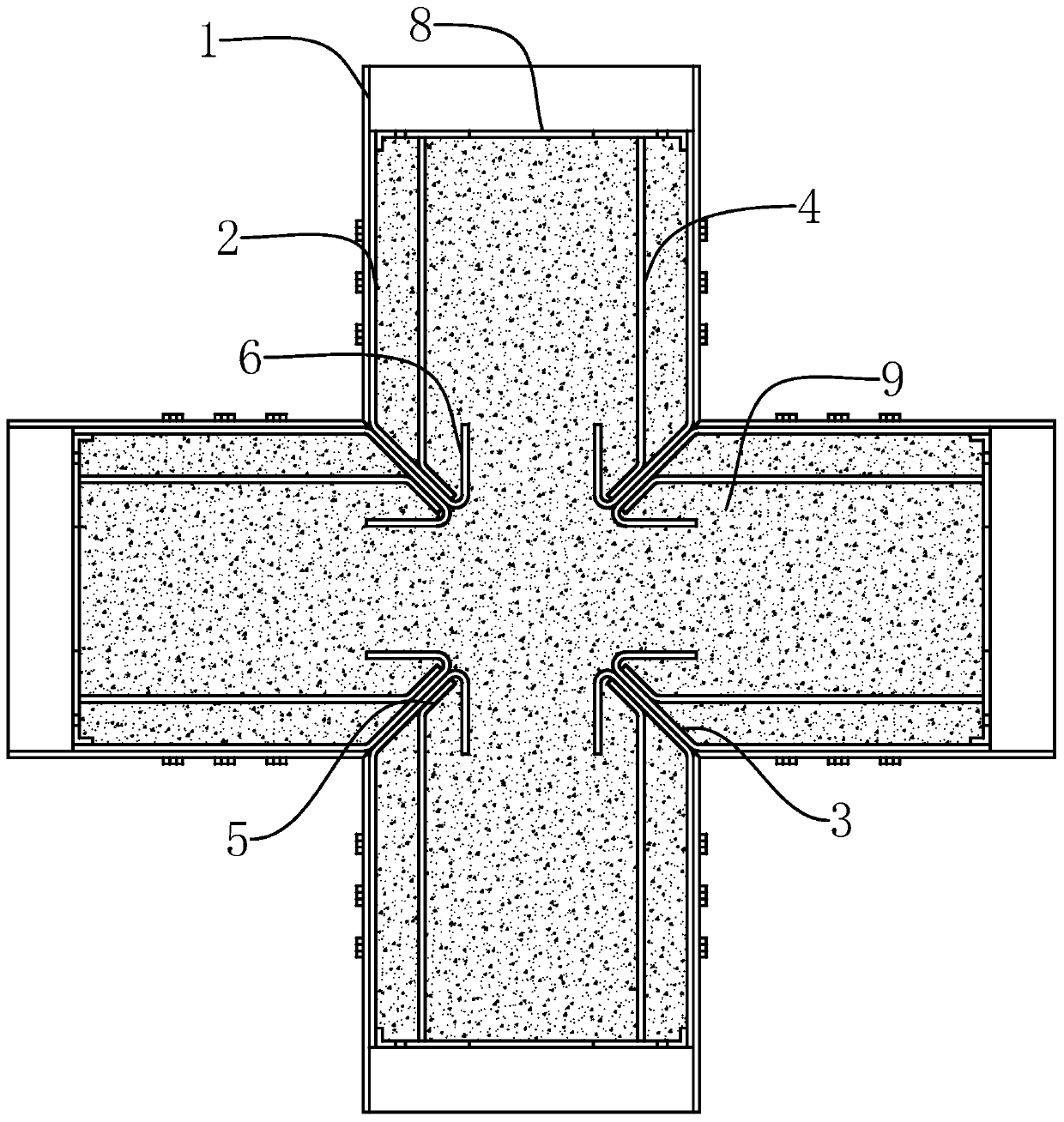

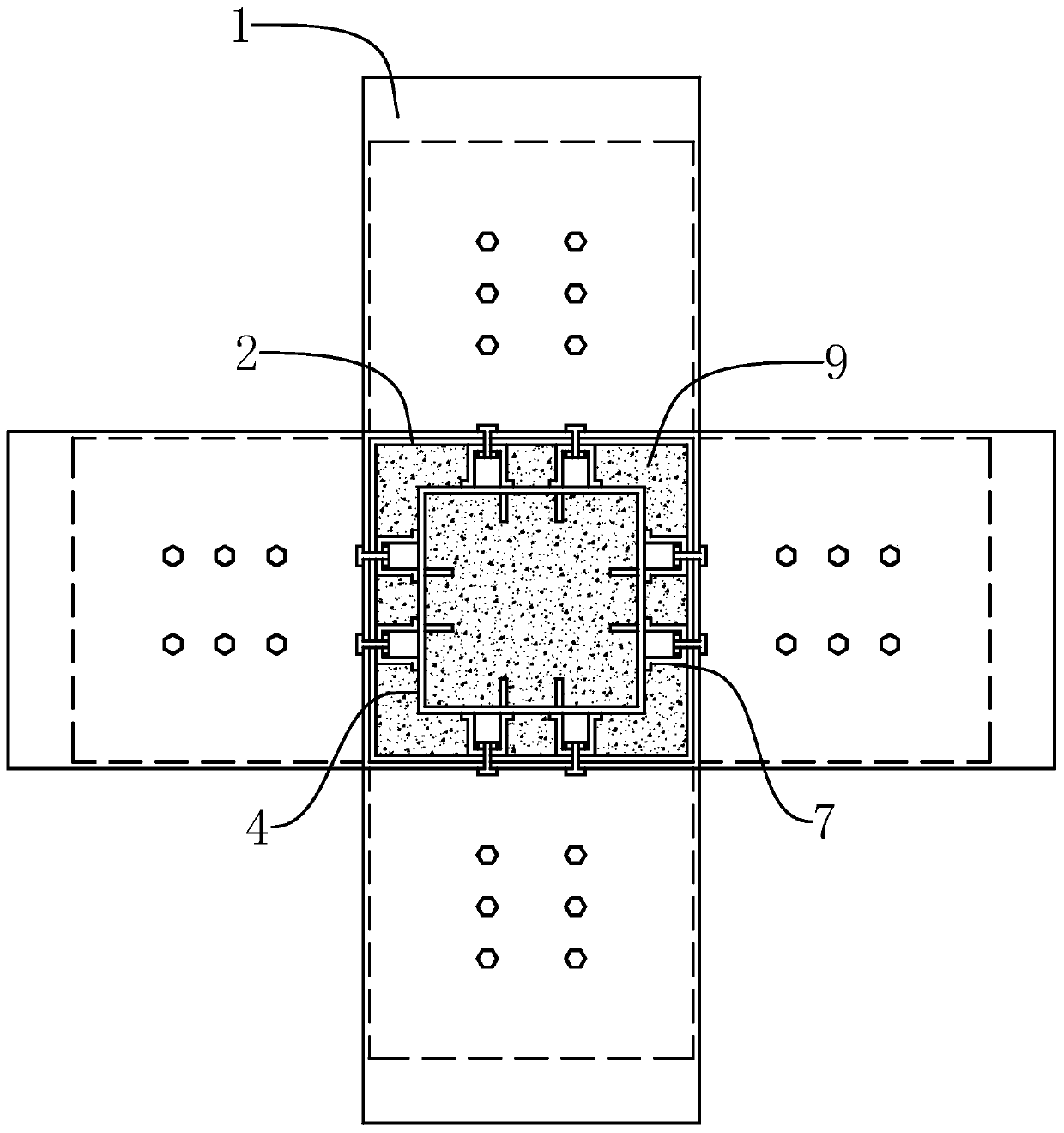

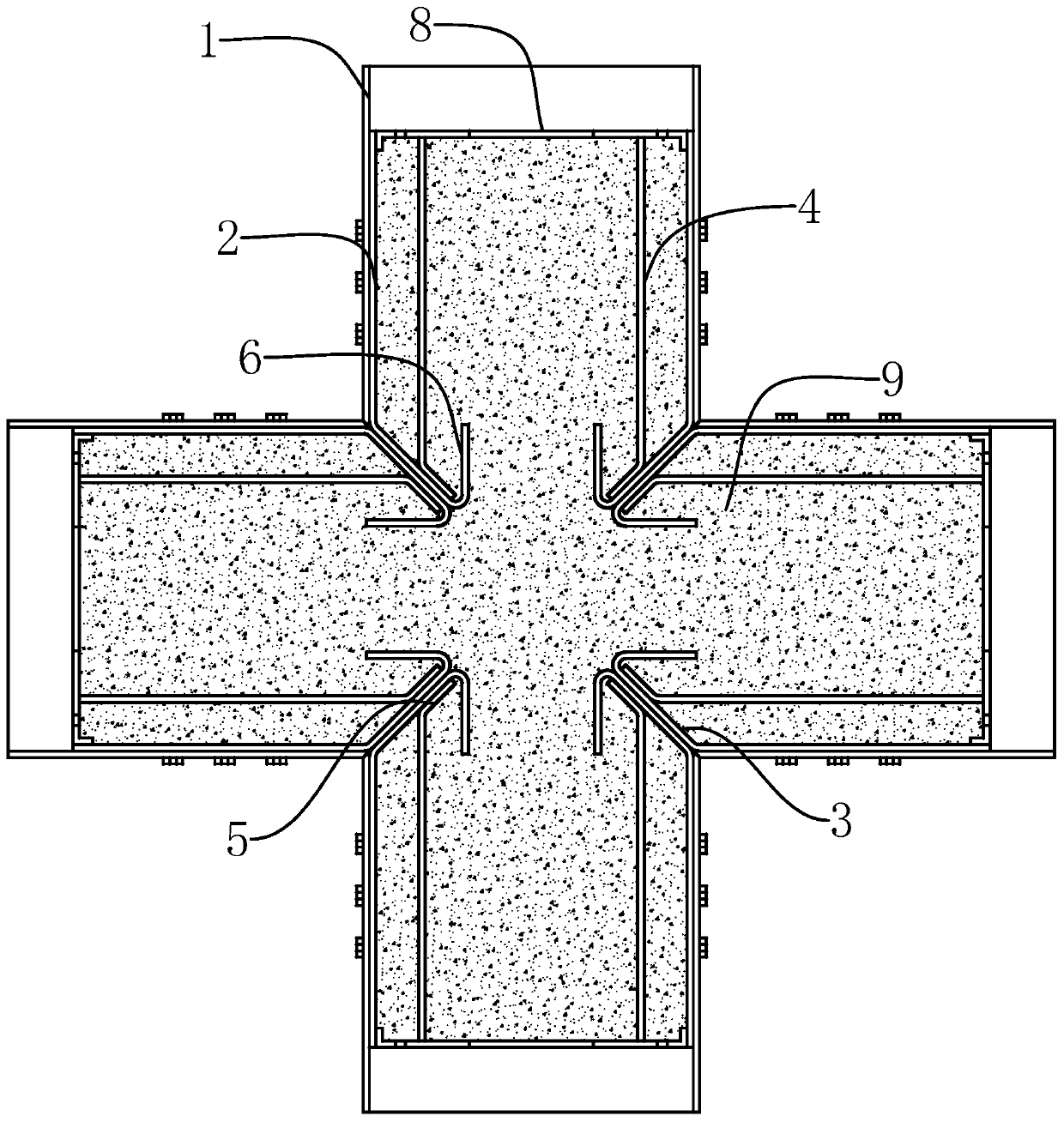

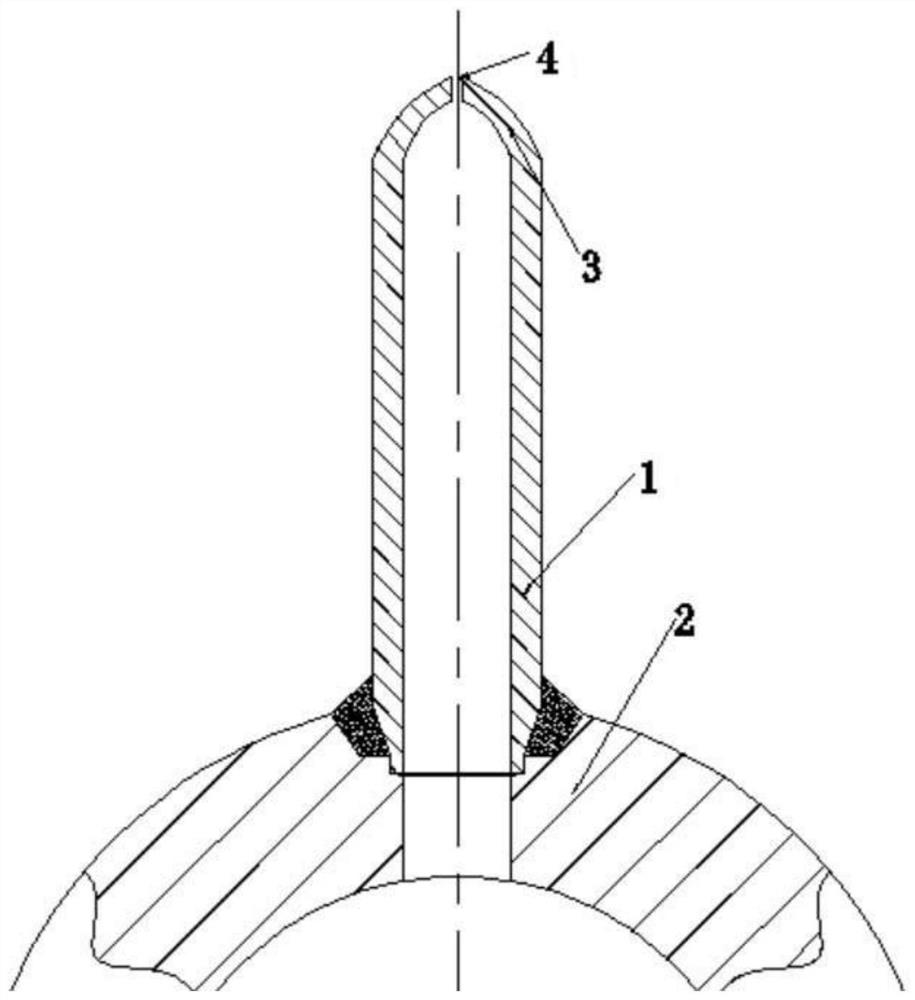

Steel structure beam column joint and manufacture and installation method thereof

InactiveCN108179811AClear forceImprove securityBuilding constructionsArchitectural engineeringUltimate tensile strength

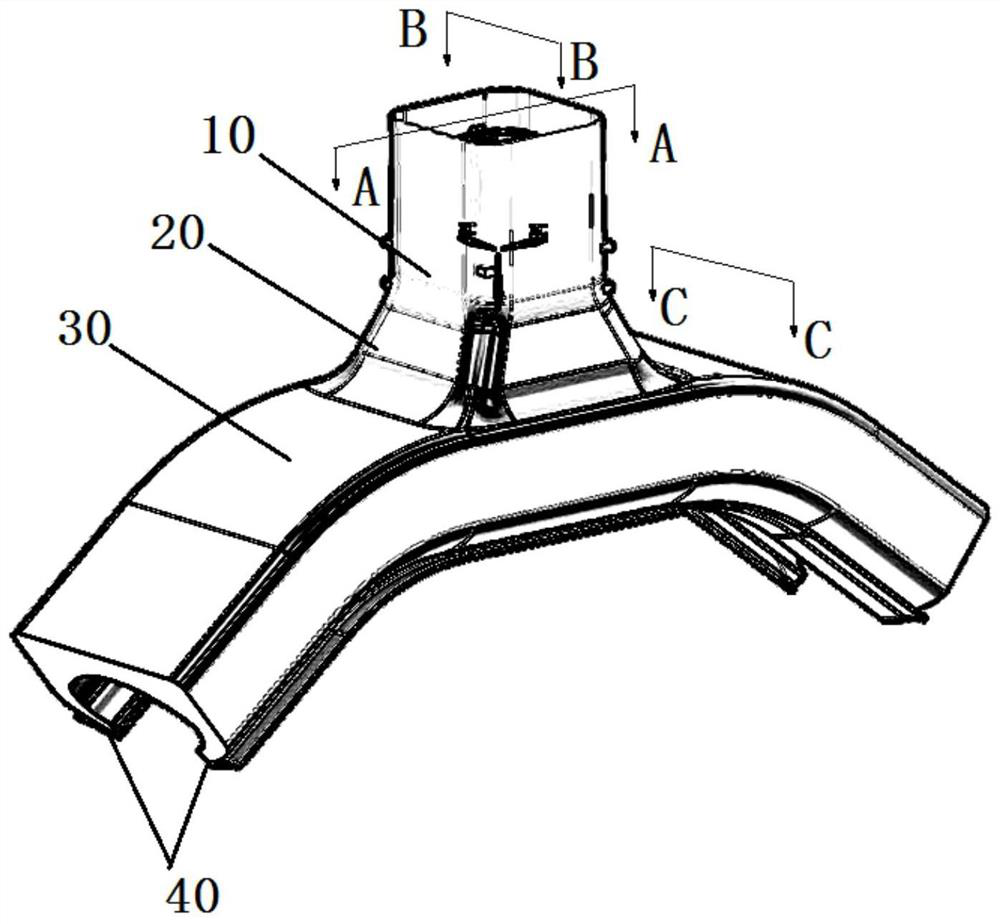

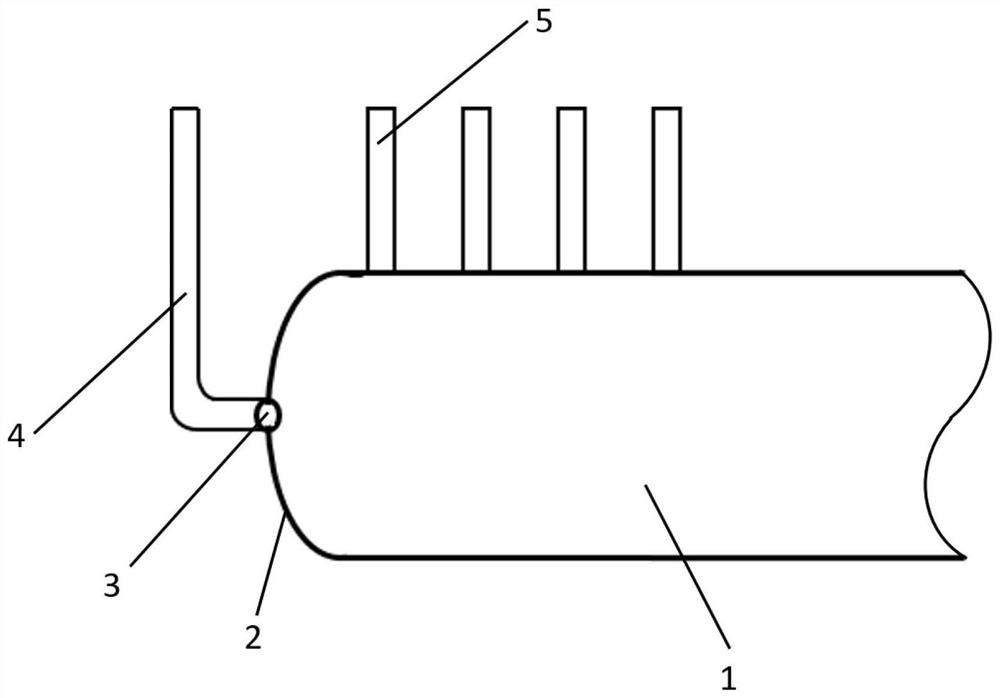

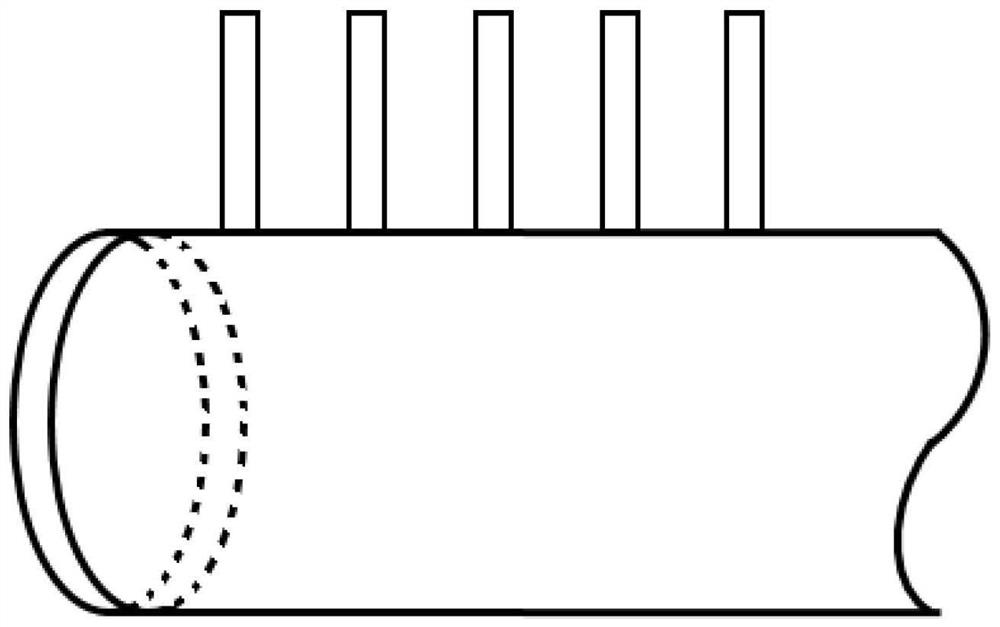

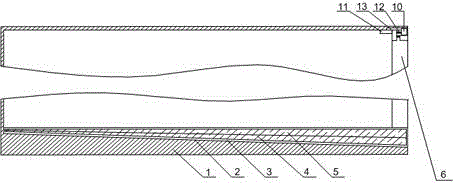

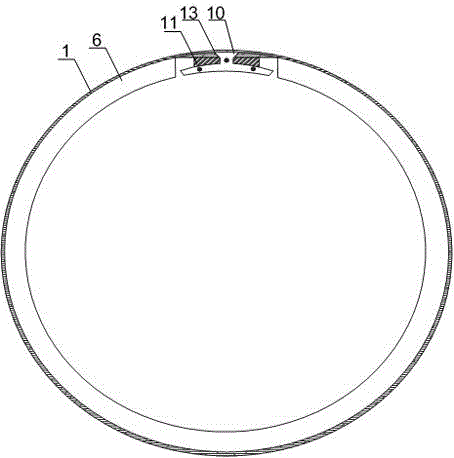

The invention provides a steel structure beam column joint and a manufacture and installation method thereof, and belongs to the field of steel structures. The problem of lower strength of an existingbeam column joint is solved. The steel structure beam column joint includes a column body, a beam body and a joint, the joint includes a center pipe and a column connecting pipe, and the column connecting pipe includes inner column connecting plates, outer column connecting plates and two side column connecting plates; the inner column connecting plates are surrounded to form inner sleeves, the outer column connecting plates are surrounded to form outer connecting pipes, and the outer side of the center pipe is sleeved with the inner sleeves; the steel structure beam column joint further includes a beam connecting pipe embedded in the beam body end portion, the beam connecting pipe includes a front beam connecting plate, a rear beam connecting plate and a side beam connecting plate, and the left and right sides of the beam body end portion and the front beam connecting plate are aslant cut; the outer column connecting plate is provided with a beam connecting hole, the outer side surface of the front beam connecting plate and the inner side surface of the inner column connecting plate are fixed in a fit mode, and the beam connecting pipe and the two side column connecting plates are surrounded in the beam bodies to form a closed grouting area; and a grouting channel is formed in the center pipe, and communicated grouting holes are formed in the pipe wall of the center pipe, theinner column connecting pipe and the front beam connecting plate. The strength of the steel structure beam column joint is higher.

Owner:新昌县丽晶工业产品设计有限公司

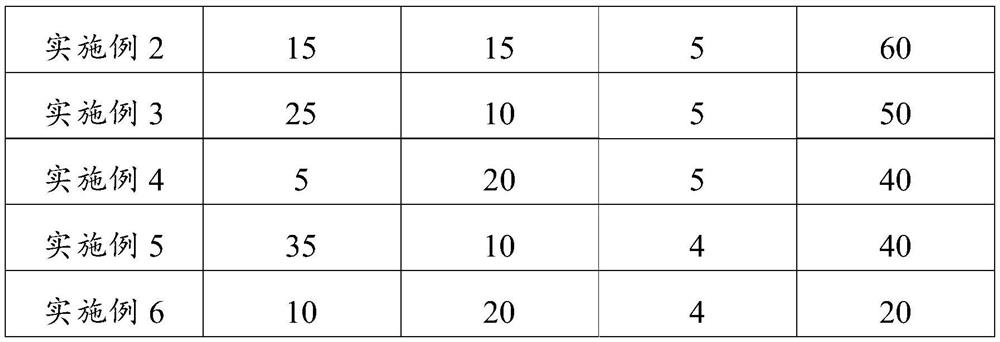

Combustion-supporting additive for hot briquetting of lignite

InactiveCN102086418ASufficient hot and cold strengthImprove thermal stabilitySolid fuelsSodium bicarbonateCombustion

The invention relates to a combustion-supporting additive for the hot briquetting of lignite. The additive comprises the following components in percentage by weight: 1-2% of sodium dodecylsulfate, 2-3% of sodium bicarbonate, 10-20% of bonding agent, 5-10% of magnesium particles, 50-60% of pine powder, 5-20% of strong oxidant, 3-8% of sulfur-fixing agent and 3-10% of industrial salt. By utilizingthe additive disclosed by the invention, the burn-out rate of the lignite can be increased, the discharge of sulfur dioxide and carbon monoxide is reduced, and the effect of saving energy is achieved.

Owner:南通欧通置业有限公司

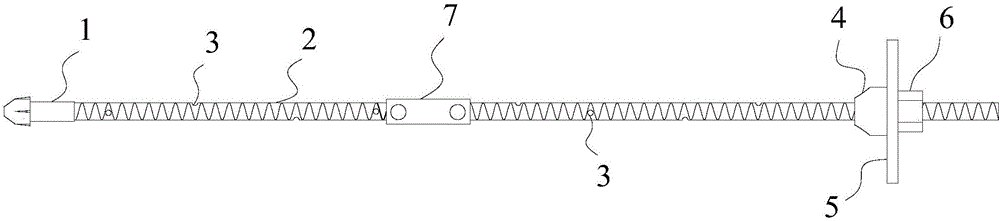

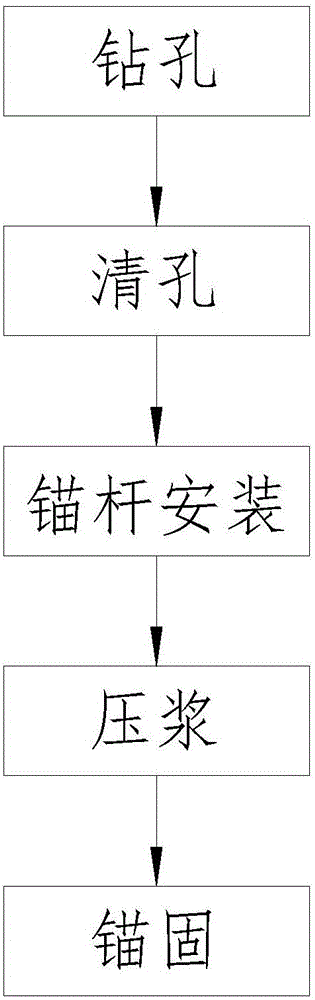

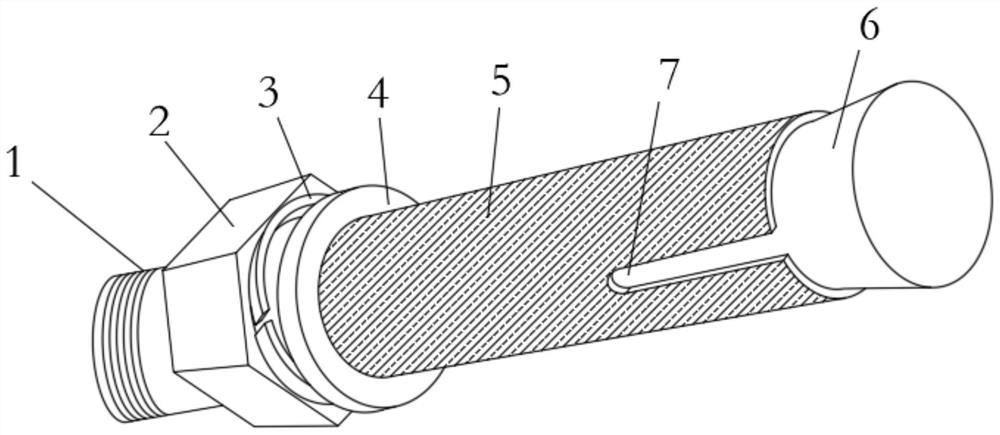

Glass fiber anchor rod and construction method

InactiveCN106523006AExcellent carrying capacityExcellent tensile strengthAnchoring boltsGlass fiberArchitectural engineering

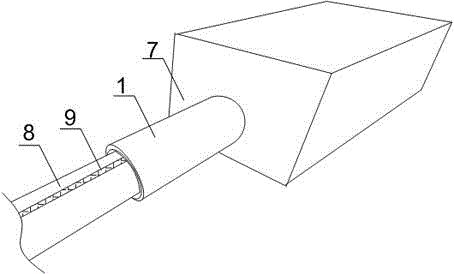

The invention discloses a glass fiber anchor rod and a construction method. The glass fiber anchor rod comprises an anchor head, a rod body, a stop-grouting plug and an anchor accessory, wherein one end of the rod body is connected with the anchor head, and the other end of the rod body is in sliding connection with the stop-grouting plug and the anchor accessory; the stop-grouting plug is located between the anchor head and the anchor accessory; the rod body is of a hollow structure and is made of glass fibers; and the rod body is provided with a plurality of openings, and the openings communicate with the hollow structure of the rod body. The method comprises the steps of drilling, hole cleaning, installation of the anchor rod, grouting, anchorage and the like. By the adoption of the glass fiber anchor rod and the construction method, the bearing capacity and the tensile capacity of the rod body can be improved advantageously, the construction cost is reduced, a whole installation hole and surrounding cracks can easily be densely filled, and overall strength is improved. By the adoption of the method, the filling effect of grout to surrounding rock cracks can be improved, the grouting compaction degree is increased, the probability of corrosion to the rod body is lowered, the service life is prolonged, construction efficiency is improved, and construction safety is improved.

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

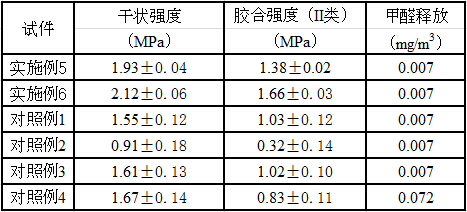

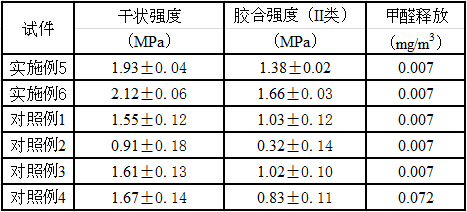

Soybean meal adhesive for blockboards, and preparation method thereof

ActiveCN111675998AImprove bonding performanceReduce usageNon-macromolecular adhesive additivesProtein adhesivesPhosphoric acidPlasma treatment

The invention discloses a soybean meal adhesive for blockboards, and a preparation method thereof. The adhesive comprises, by mass, 22-26 parts of soybean meal powder, 86 parts of a dispersing agent,2-3 parts of trypsin, 1-2 parts of a composite viscosity regulator, 2-3 parts of a branched polymer cross-linking agent and 0.04-0.04 part of calcium phosphate. The preparation method comprises the following steps: K1, performing plasma treatment on the soybean meal powder in a nitrogen atmosphere, then adding calcium chloride and the dispersing agent, performing ultrasonic treatment, adding trypsin, performing treatment at 50-60 DEG C for 20 minutes, cooling, adding phosphoric acid, and performing uniform stirring to obtain a first mixture; and K2, adding calcium phosphate and the branched polymer cross-linking agent into the first mixture, uniformly stirring, adding the composite viscosity regulator, mixing, and regulating the pH value to 9.0 to obtain the soybean meal adhesive for the blockboards. The adhesive is good in water-resistant adhesive property, and ensures the practical performance of the adhesive and the durability of the blockboards.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

Steel structure joint connection device and manufacturing method thereof

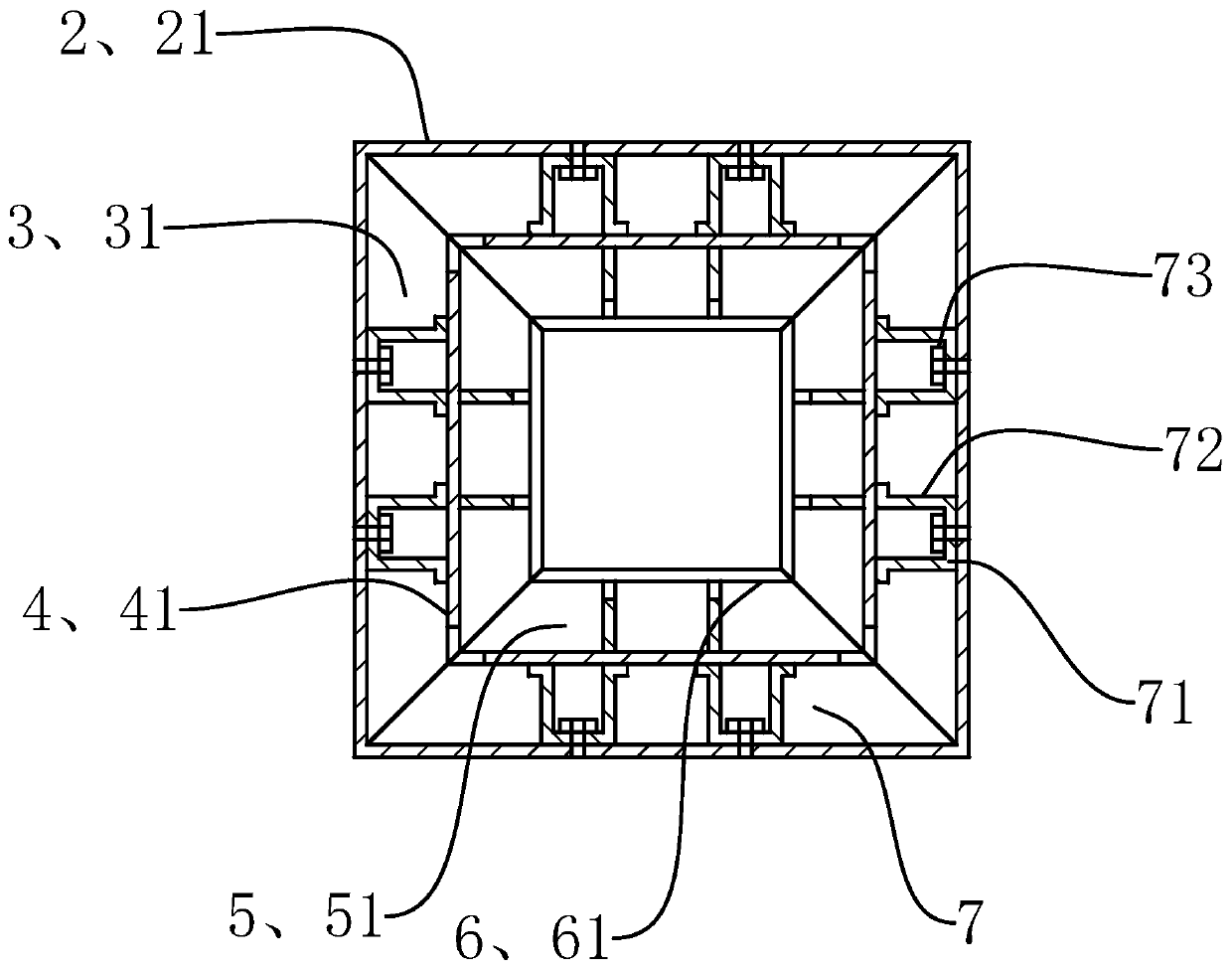

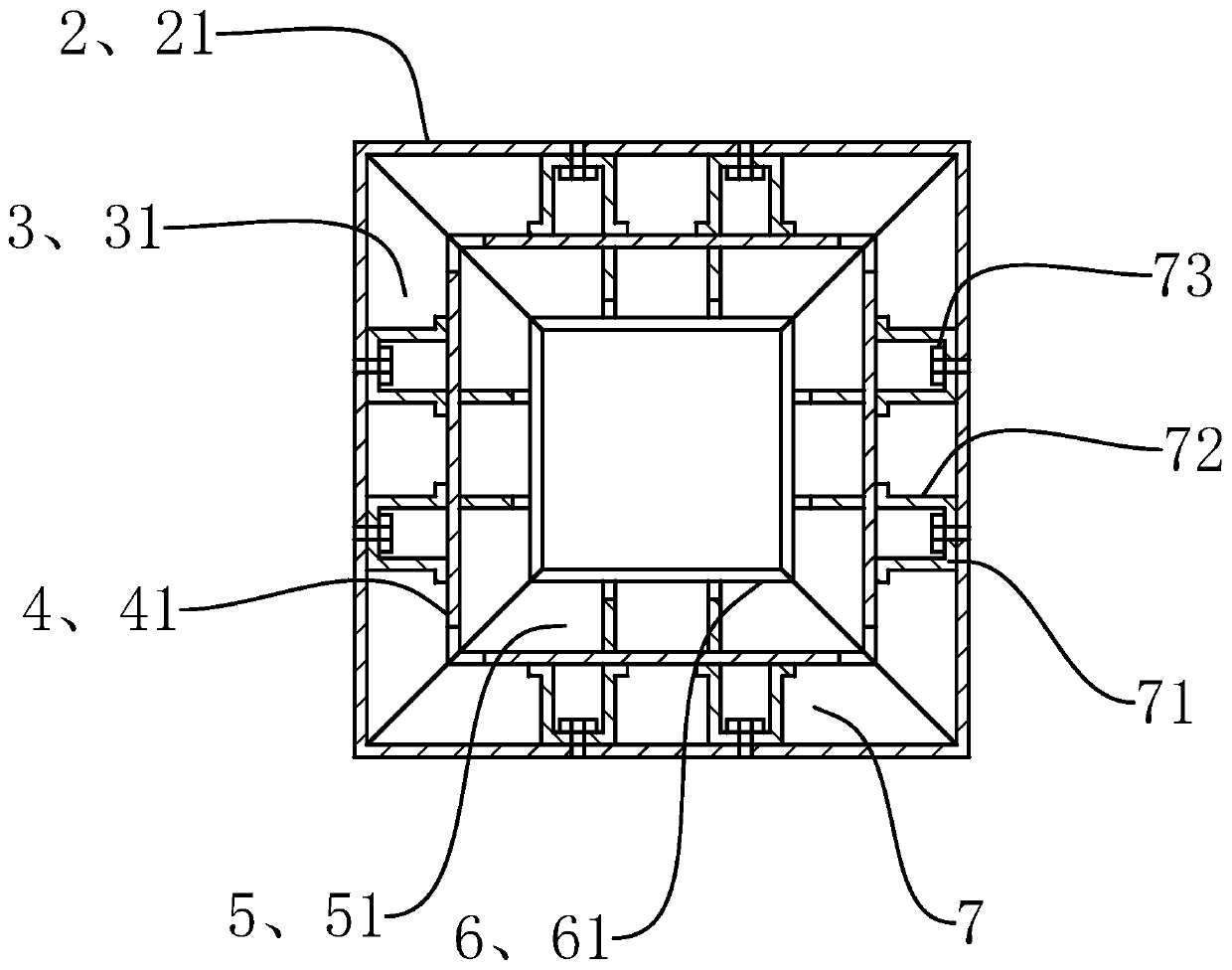

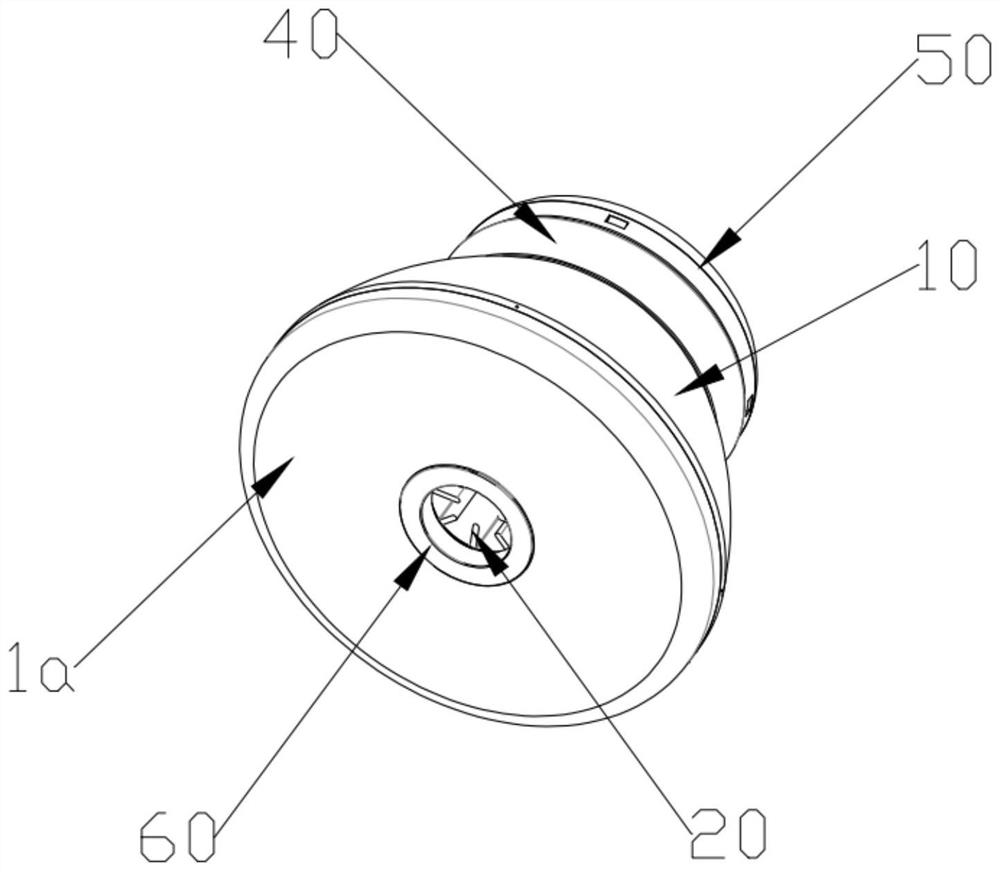

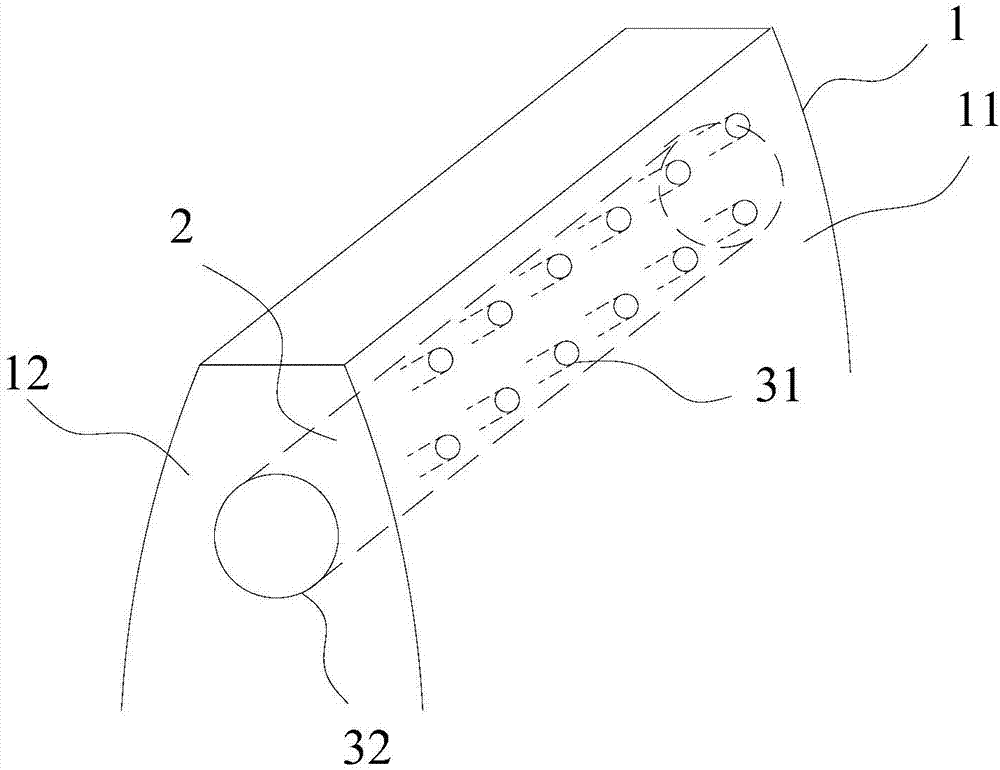

The invention provides a steel structure joint connection device and a manufacturing method thereof, and belongs to the field of steel structures. The problem that existing steel structure joints cannot be connected in a hidden mode is solved. The steel structure joint connection device is used for connecting six hollow steel pipes, a connection device comprises six connection parts, connection parts include outer connection pipes, inner join pipes, outer join pipes and inner connection pipes, connection boxes are arranged between outer connection pipes and inner connection pipes, the connection device further comprises baffles fixed on the inner walls of the top ends of the outer connection pipes, the bottom faces of the baffles abut against the top ends of the inner connection pipes in a sealing mode, grout-venting holes are formed in the baffles, any baffle is provided with a grouting opening, concrete mortar is poured into the connection parts through the grouting openings, and the six hollow steel pipes correspondingly sleeve six outer connection pipes in a matched mode and are fixed through fasteners. According to the steel structure joint connection device, the six hollow steel pipes can be connected in a high-intensive hidden mode.

Owner:东阳市智林科技有限公司

Novel carbon fiber tube processing process

InactiveCN109454893AAvoid affecting intensityReduce tanglingCoatingsTubular articlesFiberRoom temperature

The invention discloses a novel carbon fiber tube processing process. The novel carbon fiber tube processing process comprises a solution preparation procedure, a solution immersion procedure, a winding forming procedure and a curing procedure. The Novel carbon fiber tube processing process is characterized by specifically including the steps that S1, a solution is prepared and then put in a container; S2, a carbon fiber composite material is immersed into the prepared solution so that the surface of the material is completely dipped in the solution; S3, the carbon fiber composite material with the solution is winded onto a winding die core, and the carbon fiber composite material is shaped through rotation of the winding die core; and S4, the shaped carbon fiber composite material is cured in a curing furnace. Curing is performed in the curing furnace with the constant temperature being 150 DEG C for one hour in the curing process, then the temperature of the curing furnace is decreased to reach the room temperature, meanwhile the curing furnace is made to be in a vacuum state through a vacuum pump for performing curing again for one hour, thus solvent is completely removed, and the shaping strength is not affected.

Owner:滁州市润琦碳纤维制品有限公司

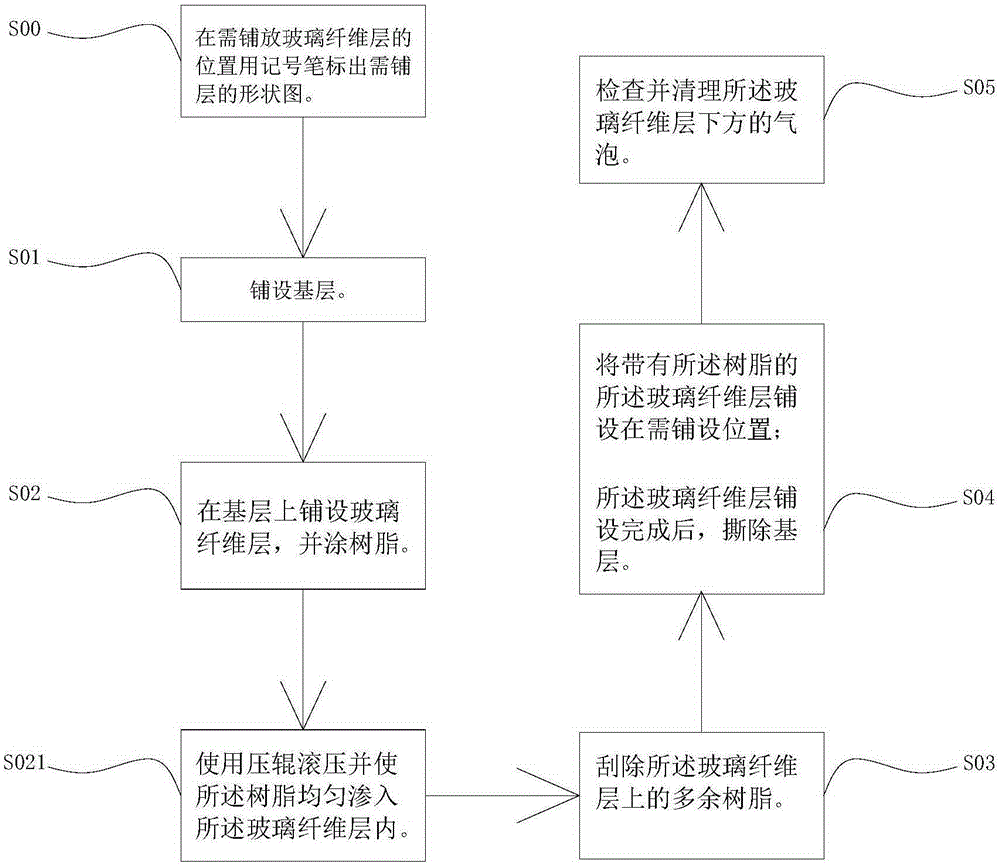

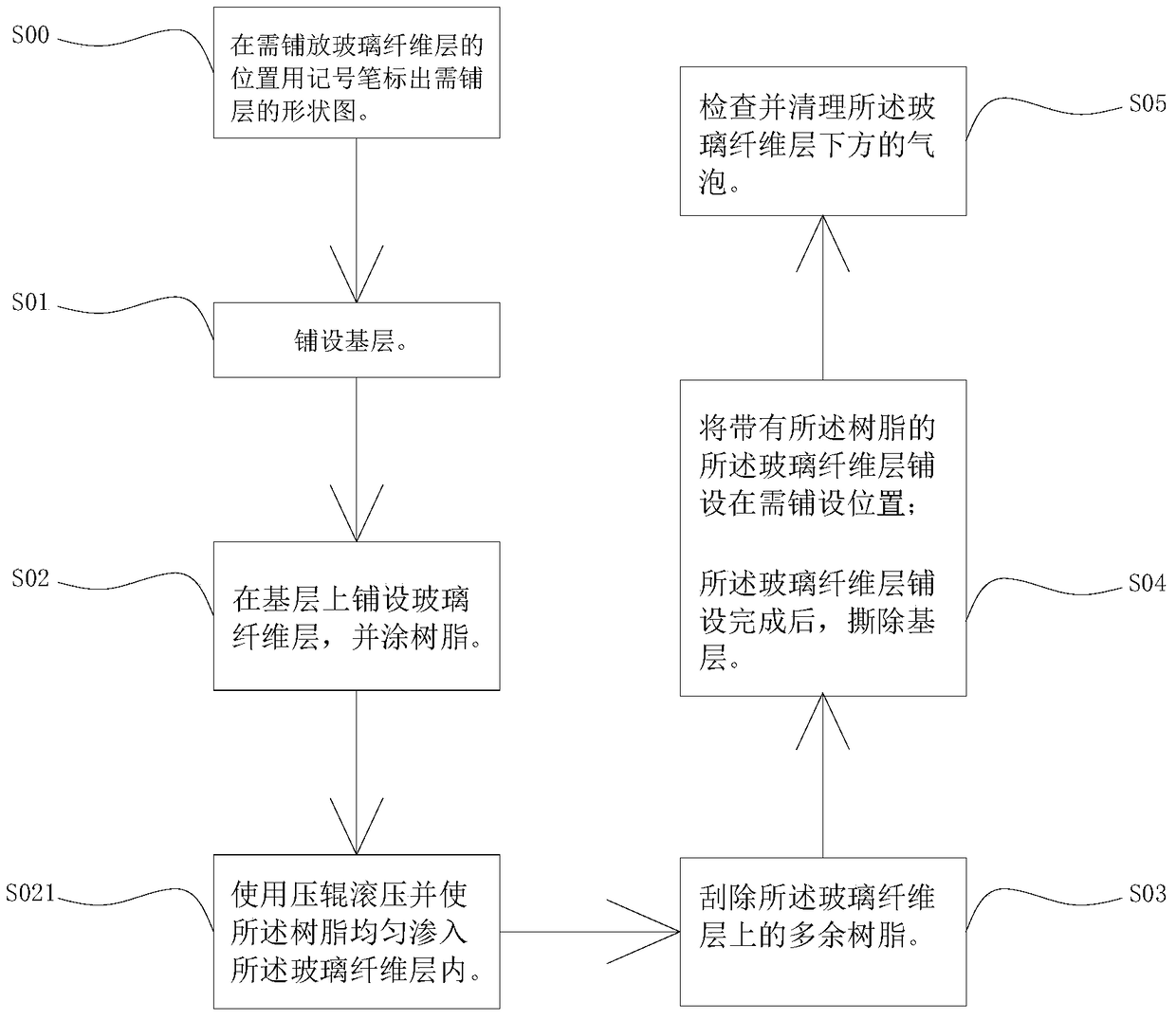

Hand lay-up molding method

The invention provides a hand lay-up molding method. The hand lay-up molding method comprises the following steps of S01: laying a base layer; S02: laying a glass fiber cloth layer on the base layer, and coating resin on the glass fiber cloth layer in a rolling manner, so as to enable the resin to permeate uniformly into the glass fiber cloth layer; S03: scraping the excessive resin after the step S02; S04: laying the glass fiber cloth layer in the step S03 to a position needing hand lay-up, then compacting, and finally tearing off the base layer.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

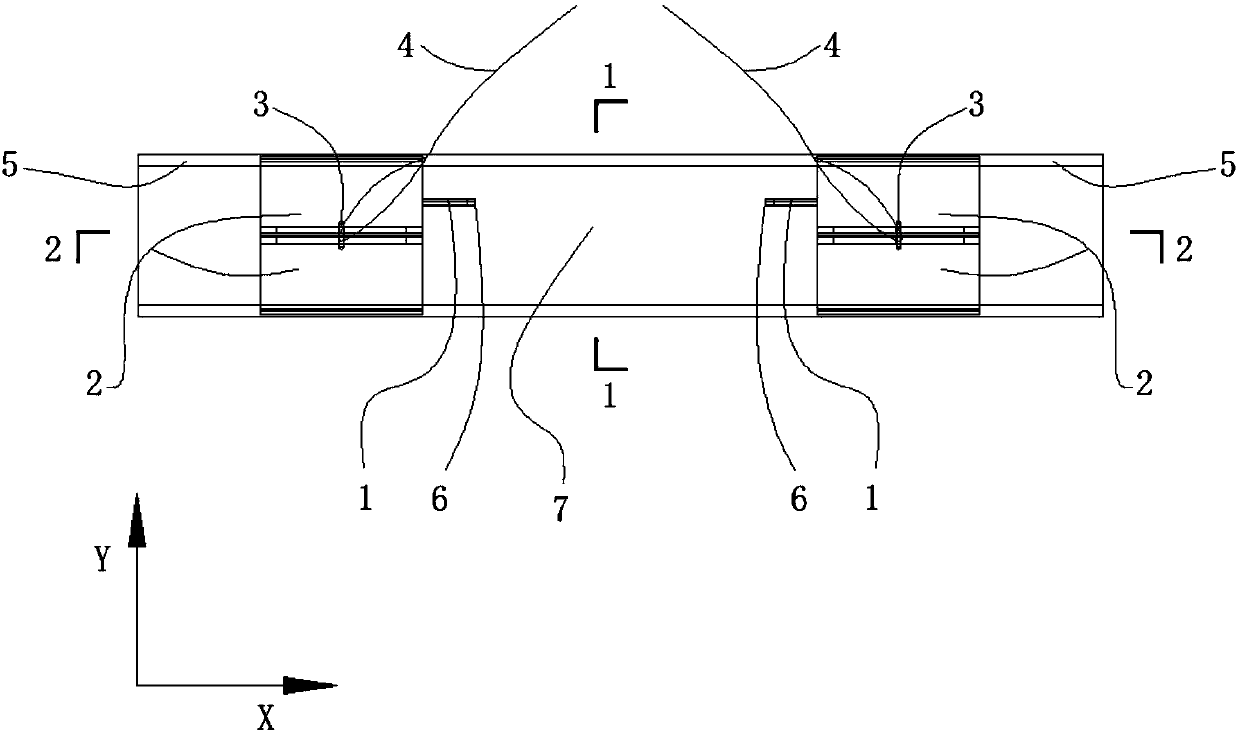

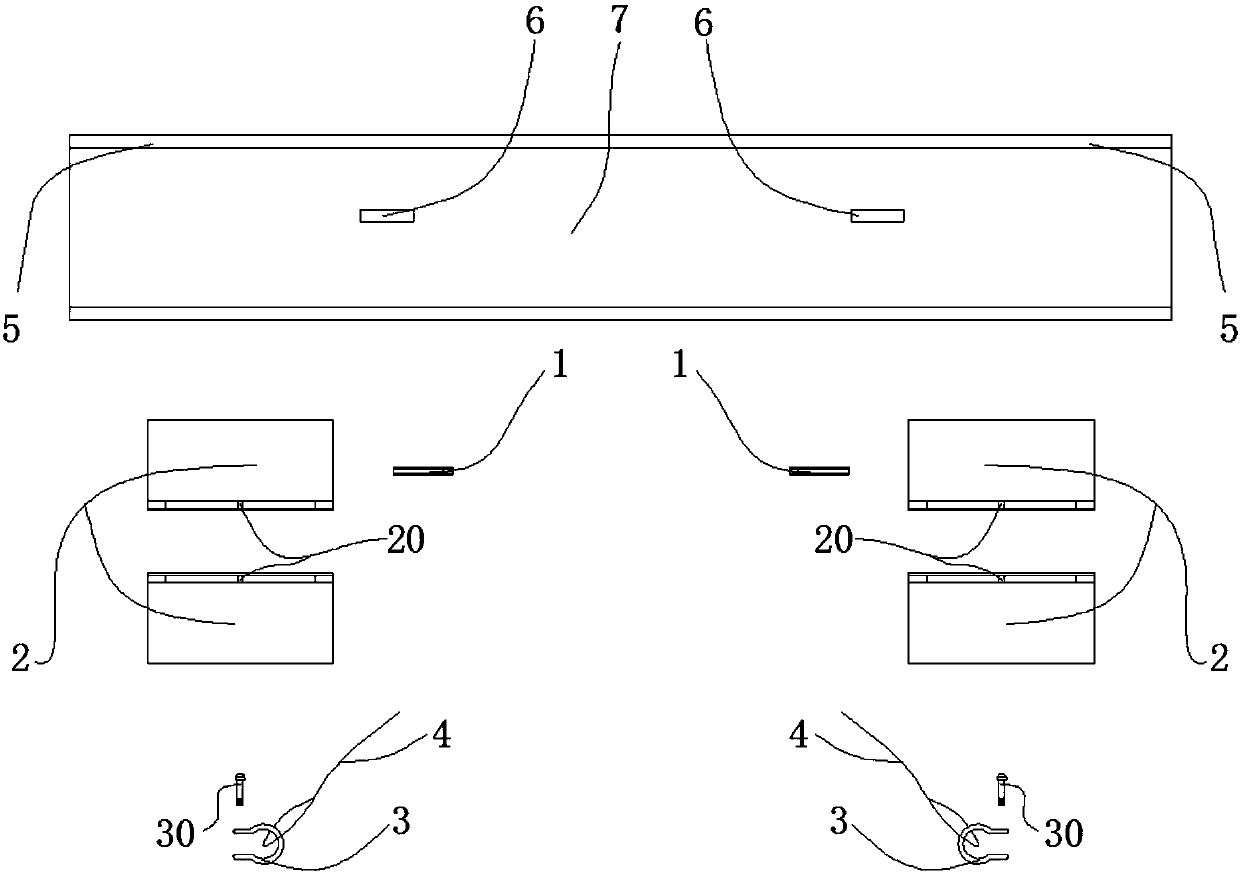

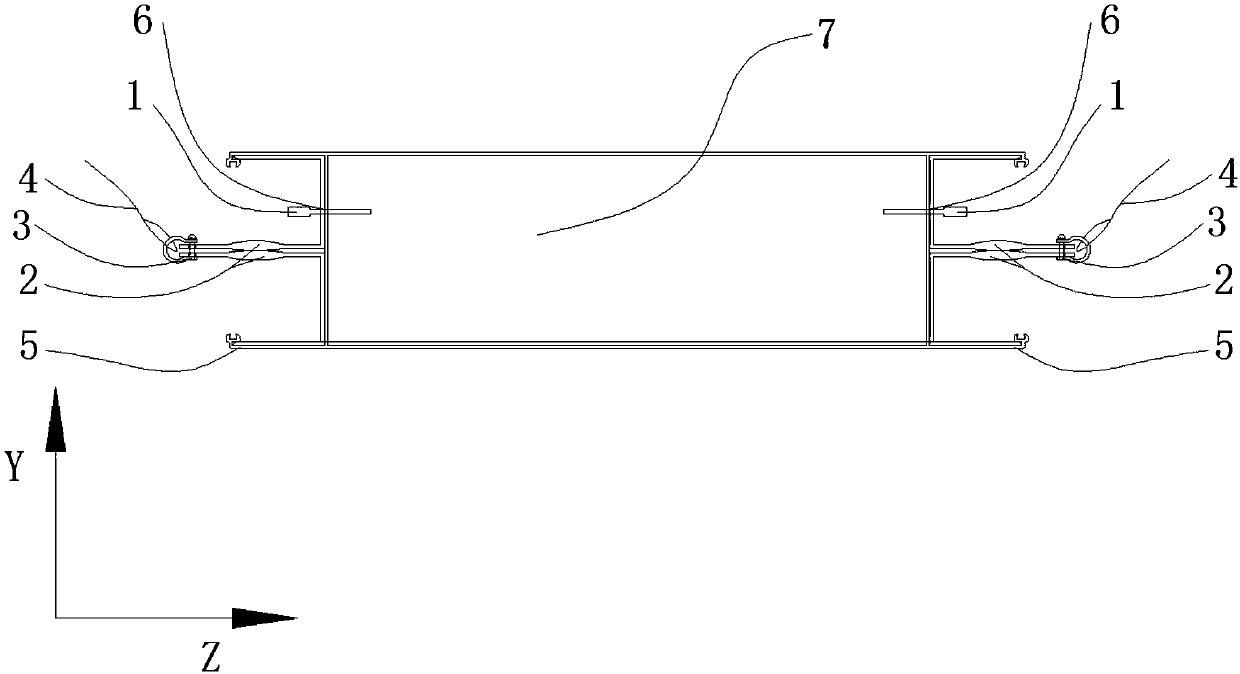

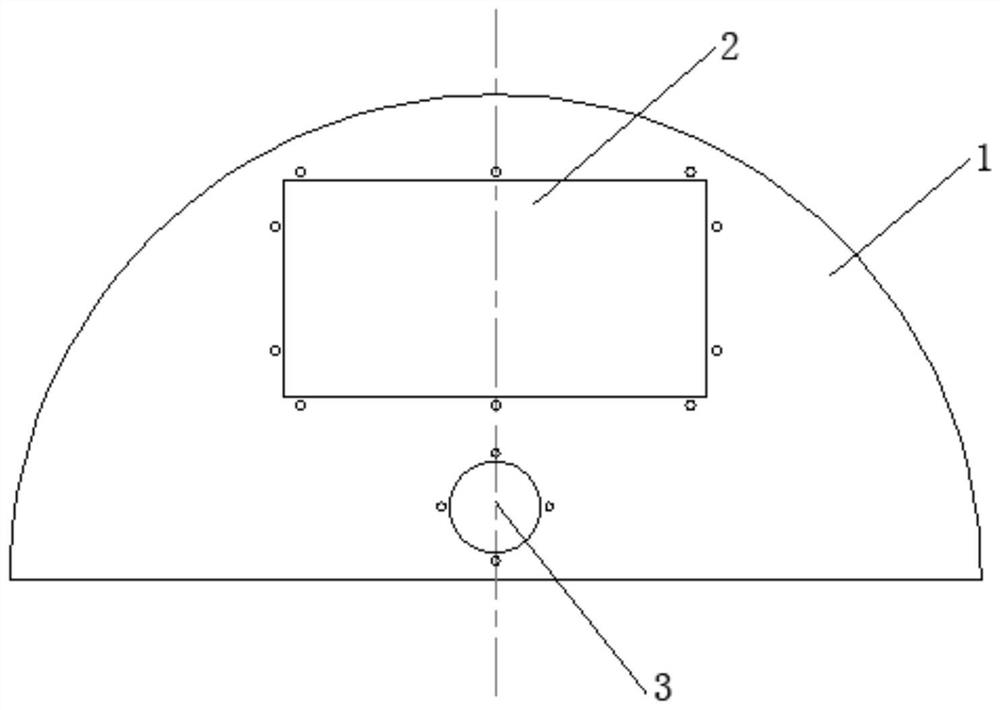

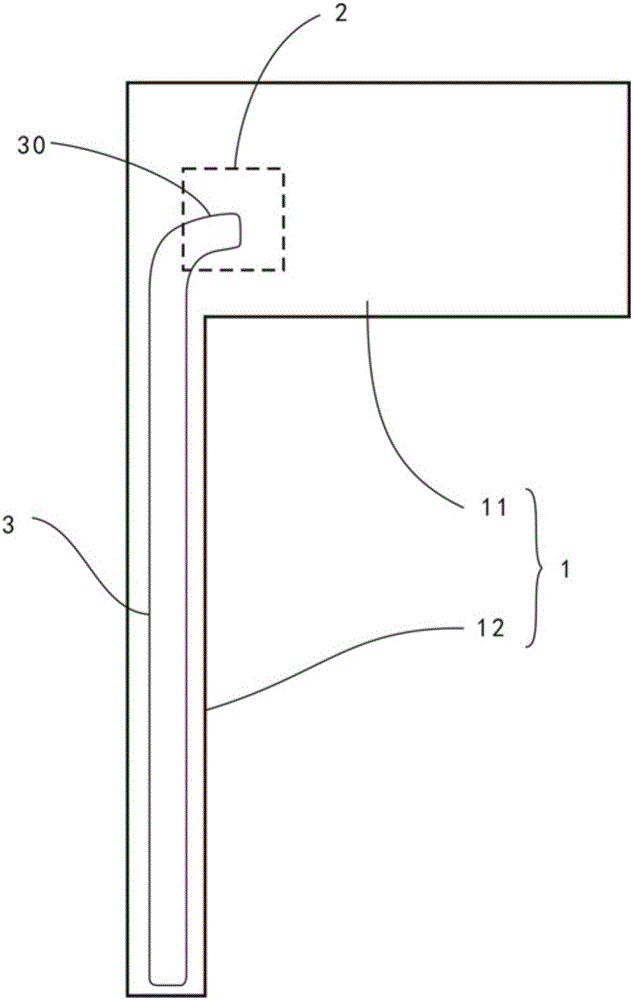

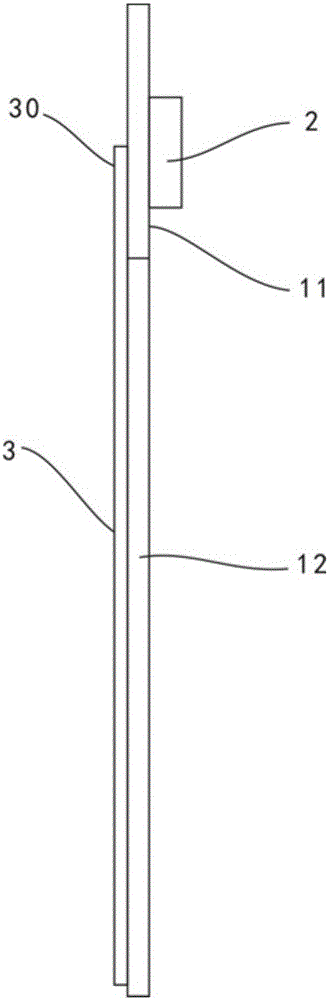

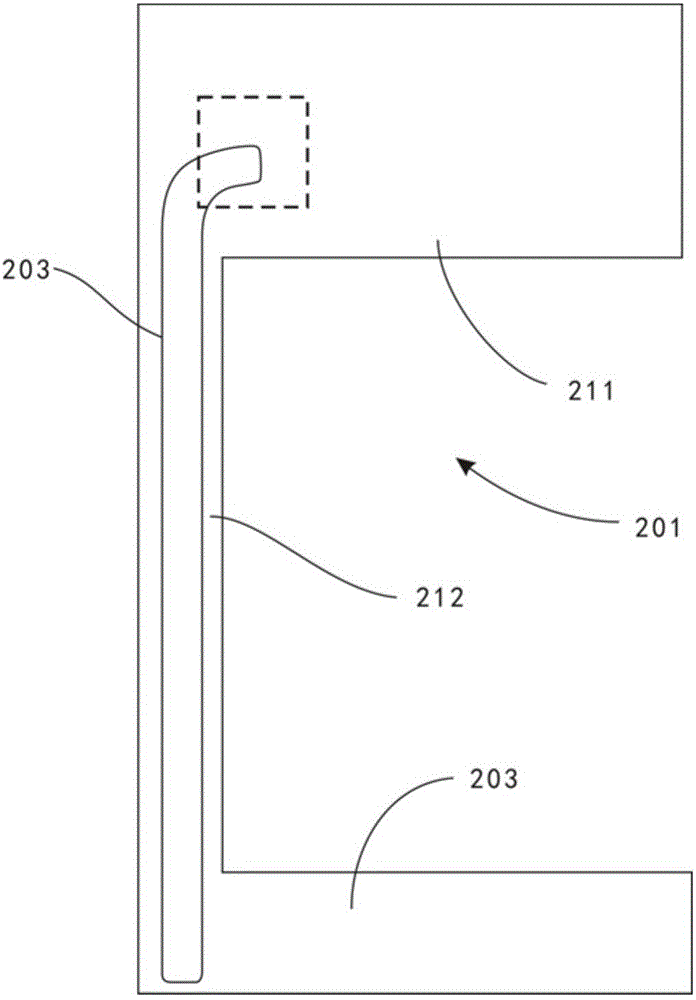

Curtain wall hoisting device

The invention provides a curtain wall hoisting device. The curtain wall hoisting device comprises curtain wall sliding grooves formed in a curtain wall unit body, and combination hanging pieces assembled in the curtain wall sliding grooves and used for being connected with hoist cables; the combination hanging pieces are slidably arranged in the curtain wall sliding grooves; bolt holes are formedin the curtain wall sliding grooves, and bolts are inserted in the bolt holes; and the bolts abut against the combination hanging pieces so as to restrain the displacement of the combination hanging pieces in the curtain wall sliding grooves. The curtain wall sliding grooves are formed in the curtain wall unit body integrally, the combination hanging pieces are slidably mounted in the curtain wallsliding grooves and used for being connected with the hoist cables, the bolt holes are formed in the curtain wall sliding grooves for mounting the bolts so as to position the combination hanging pieces, and thus the curtain wall hoisting device can be overall assembled detachably and is convenient to mount and demount; and the curtain wall sliding grooves are formed in the curtain wall unit bodyintegrally, a welding seam and cutting are avoided, damage and deformation of curtain wall materials are avoided, the influence on the strength and using function of the curtain wall materials is avoided, and thus the curtain wall materials have good strength and rigidity.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

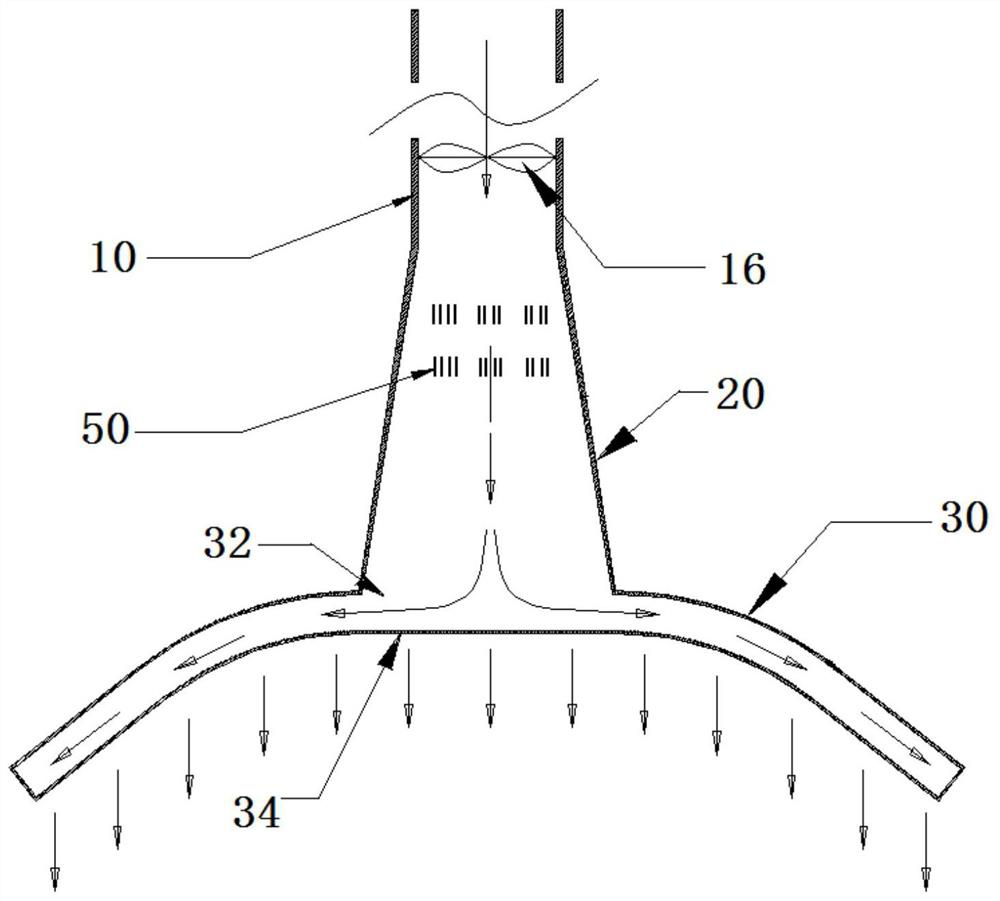

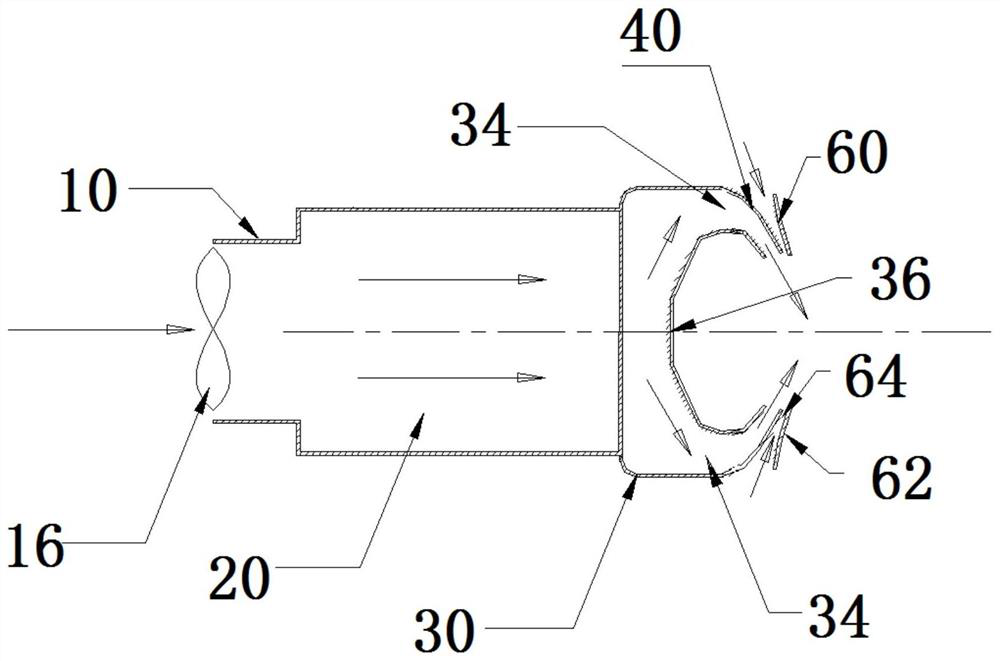

Blade gas-heat deicing system and mounting method thereof

ActiveCN111749857AEasy to installEasy to disassembleWind motor supports/mountsMachines/enginesEpoxyGlass fiber

The invention relates to the field of blade gas-heat deicing, in particular to a blade gas-heat deicing system and a mounting method thereof. The blade gas-heat deicing system comprises a heater, a ventilation pipeline, a plurality of hoops, an air blower, a baffle plate and a wiring support, the baffle plate divides a leading edge cavity between a web and the leading edge of a blade into a firstleading edge cavity and a second leading edge cavity, an air inlet of the heater is connected with an air outlet of the air blower, an air outlet of the heater communicates with an air inlet in one end of the ventilation pipeline, and the other end of the ventilation pipeline penetrates through a mounting hole and is located in the first leading edge cavity of the blade. According to the blade gas-heat deicing system and the mounting method thereof, the baffle plate is bonded to the blade, so that it is guaranteed that no gap exists between the baffle plate and the blade and the baffle plate and the blade are firmly fixed, and hot air is prevented from escaping; and the ventilation pipeline and the heater are installed by adopting the hoops, and bonding is carried out on a signal line anda power line by adopting an adhesive tape, so that the content of mounting epoxy resin hand lay-up soaked in glass fiber cloth is greatly reduced, pollution and harm to the human body are reduced, theconstruction time is saved, the cost is reduced, and the shutdown power generation loss of an owner is reduced.

Owner:HUNAN TUOTIAN ENERGY SAVING CONTROL TECH

Air duct air outlet structure and clothes nursing machine

PendingCN112080916AImprove utilization efficiencyIncrease pressureIroning apparatusTextiles and paperNursing careEngineering

The invention relates to an air duct air outlet structure and a clothes care machine. The air duct air outlet structure comprises an air inlet duct, a pressurizing air duct, an induced air duct and aspraying air duct which sequentially communicate, wherein the flowing cross sectional area of the pressurizing air duct is gradually enlarged in the air flowing direction; and the flow cross sectionalareas of the induced air duct and the spraying air duct are both smaller than that of the pressurizing air duct. According to the air duct air outlet structure, hydromechanics characteristics are fully utilized, the pressure of air in the air duct is increased through the arrangement of the flowing cross section area of the pressurizing air duct, the air outlet width is widened in combination with the induced air duct, and therefore, clothes can be comprehensively nursed along the width of the clothes. In addition, by means of the arrangement of the flow cross sectional areas of the induced air duct and the spraying air duct, the fluid speed is increased, then the speed and strength of airflow acting on the surface of the clothes are effectively enhanced, the effects of effective shaping,peculiar smell removal, sterilization and the like are achieved, the nursing effect is better, the nursing period can be shortened, and the user experience is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

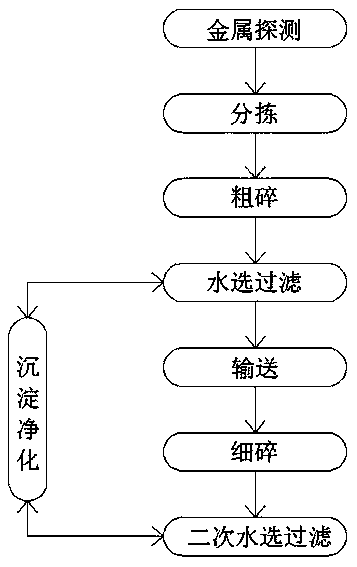

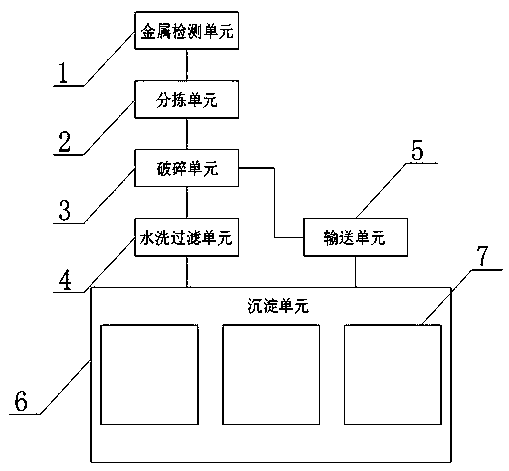

Construction waste regeneration treatment system and treatment method thereof

InactiveCN111318551AInfluence intensityAffect the safety of useConstruction waste recoverySolid waste disposalEnvironmental engineeringWaste material

The invention provides a construction waste regeneration treatment system and a treatment method thereof. The construction waste regeneration treatment system comprises a metal detection unit, a sorting unit, a crushing unit, a washing and filtering unit, a conveying unit and a precipitation unit. The construction waste regeneration treatment method comprises the following steps of metal detection, sorting, coarse crushing, water separation and filtering, precipitation and purification, conveying, fine crushing, and secondary water separation and filtering. According to the construction wasteregeneration treatment method, concrete is subjected to washing and filtering after coarse crushing and fine crushing, after concrete waste particles are put into water, loose parts and weathered parts in concrete waste are converted into smaller particles in water, then the concrete waste is filtered through a filter screen, infirm parts in the concrete waste can thus be effectively removed, andthe situation that the strength of the concrete waste serving as concrete aggregate is affected, and consequently the strength and the using safety of the concrete are affected is avoided.

Owner:福建莲春环保科技有限公司

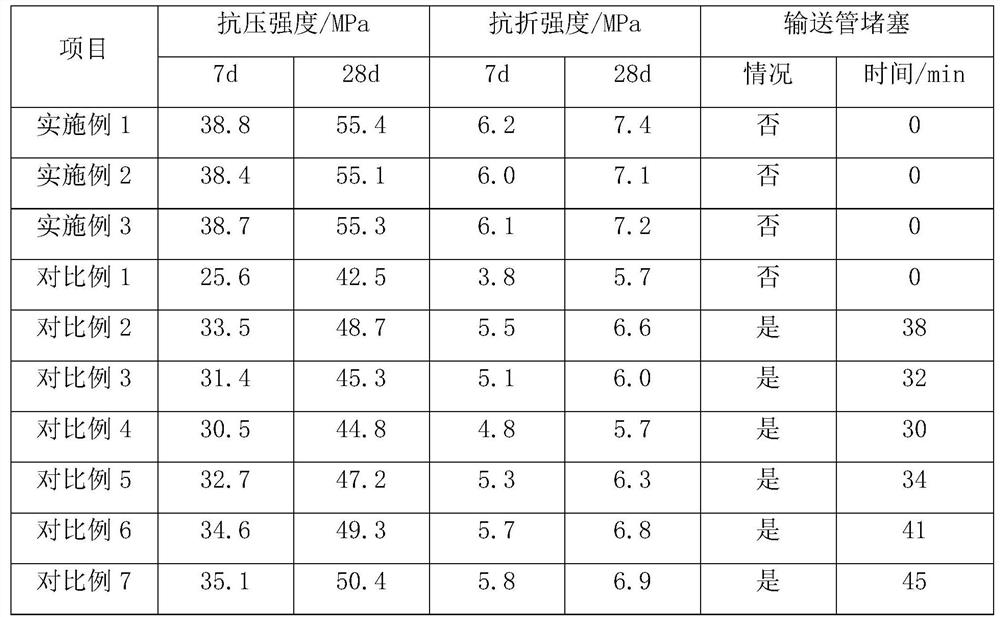

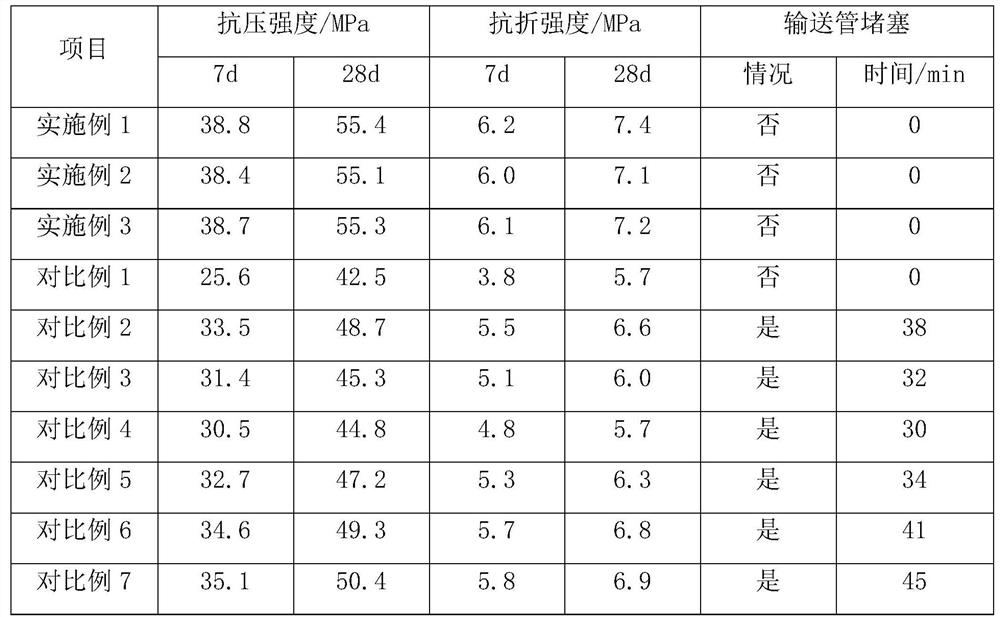

Pump concrete and preparation method thereof

ActiveCN112851239AIncrease elasticityAvoid easy cloggingCement mixing apparatusFiberUltimate tensile strength

The invention relates to the field of concrete, and particularly discloses pump concrete and a preparation method thereof. The pump concrete is prepared from the following raw materials in parts by weight: 280 to 400 parts of cement, 50 to 70 parts of fly ash, 80 to 100 parts of mineral powder, 585 to 680 parts of river sand, 1050 to 1110 parts of coated broken stone, 140 to 155 parts of water, 7 to 10.5 parts of an additive and 8 to 12 parts of modified composite fibers, wherein the modified composite fibers are prepared by mixing natural bamboo fibers and polyurethane fibers. The preparation method comprises the steps of weighing the coated broken stone, the modified composite fibers and the water, mixing and stirring to obtain a mixture; weighing and adding cement, fly ash, mineral powder, river sand and an additive into the mixture prepared in the step S1, preparing a concrete mixture after stirring and mixing, pumping and pouring the concrete mixture into a mold, and obtaining pump concrete after curing. The pump concrete has the advantages that the pump concrete is not easy to block a pipeline when being pumped, and the pump concrete has higher strength after being cured.

Owner:广州市粤砼混凝土有限公司

A steel structure node connection device and manufacturing method thereof

The invention provides a steel structure joint connection device and a manufacturing method thereof, and belongs to the field of steel structures. The problem that existing steel structure joints cannot be connected in a hidden mode is solved. The steel structure joint connection device is used for connecting six hollow steel pipes, a connection device comprises six connection parts, connection parts include outer connection pipes, inner join pipes, outer join pipes and inner connection pipes, connection boxes are arranged between outer connection pipes and inner connection pipes, the connection device further comprises baffles fixed on the inner walls of the top ends of the outer connection pipes, the bottom faces of the baffles abut against the top ends of the inner connection pipes in a sealing mode, grout-venting holes are formed in the baffles, any baffle is provided with a grouting opening, concrete mortar is poured into the connection parts through the grouting openings, and the six hollow steel pipes correspondingly sleeve six outer connection pipes in a matched mode and are fixed through fasteners. According to the steel structure joint connection device, the six hollow steel pipes can be connected in a high-intensive hidden mode.

Owner:东阳市智林科技有限公司

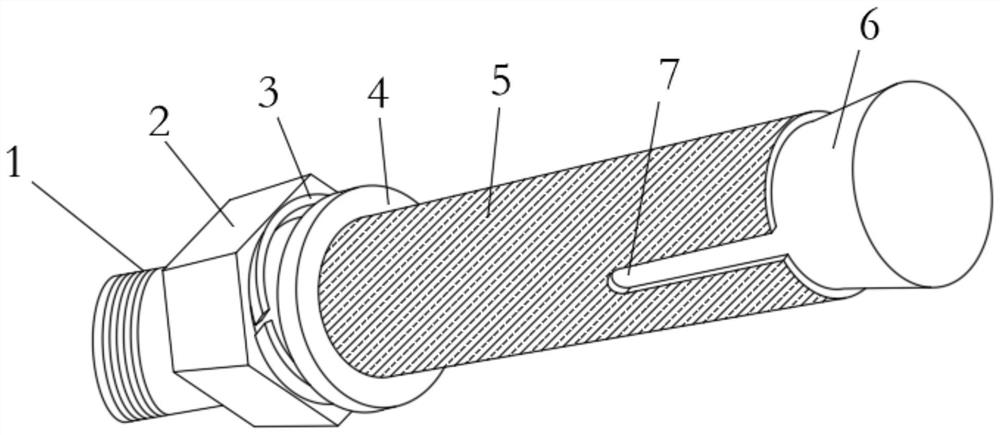

Boiler header connecting pipe with hot spinning hydraulic pressure end socket and machining method thereof

The invention discloses a boiler header connecting pipe with a hot spinning hydraulic pressure end socket and a machining method thereof, and belongs to the technical field of boiler equipment manufacturing. The connecting pipe comprises a connecting pipe body, one end of the connecting pipe body is provided with the hydraulic pressure end socket in a hot spinning mode, the other end of the connecting pipe body is provided with a welding groove, a hot spinning process hole is reserved in the hydraulic pressure end socket, during a hydraulic pressure test, the connecting pipe body and a headerbody are welded and fixed, and the hot spinning process hole is blocked. According to the boiler header connecting pipe and the machining method thereof, tedious working procedures of processing the welding groove of a blocking plate, processing the blocking plate, sealing and welding the blocking plate and the like are avoided, and waste of raw materials for additionally processing the blocking plate is avoided; the hydraulic pressure end socket integrated with the connecting pipe body is firm and reliable, and the problem of leakage of the hydraulic pressure test is avoided; and for the process hole reserved by a hot spinning forming process, the strength of the process hole can meet the requirements of the hydraulic pressure test of all ultra-supercritical unit boiler headers at presentafter the process hole is blocked only by using methods such as arc welding, only the hydraulic pressure end socket needs to be cut off after the test, and therefore a large amount of manpower and material resources are saved, the production efficiency is improved, and the cost of enterprises is remarkably lowered.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

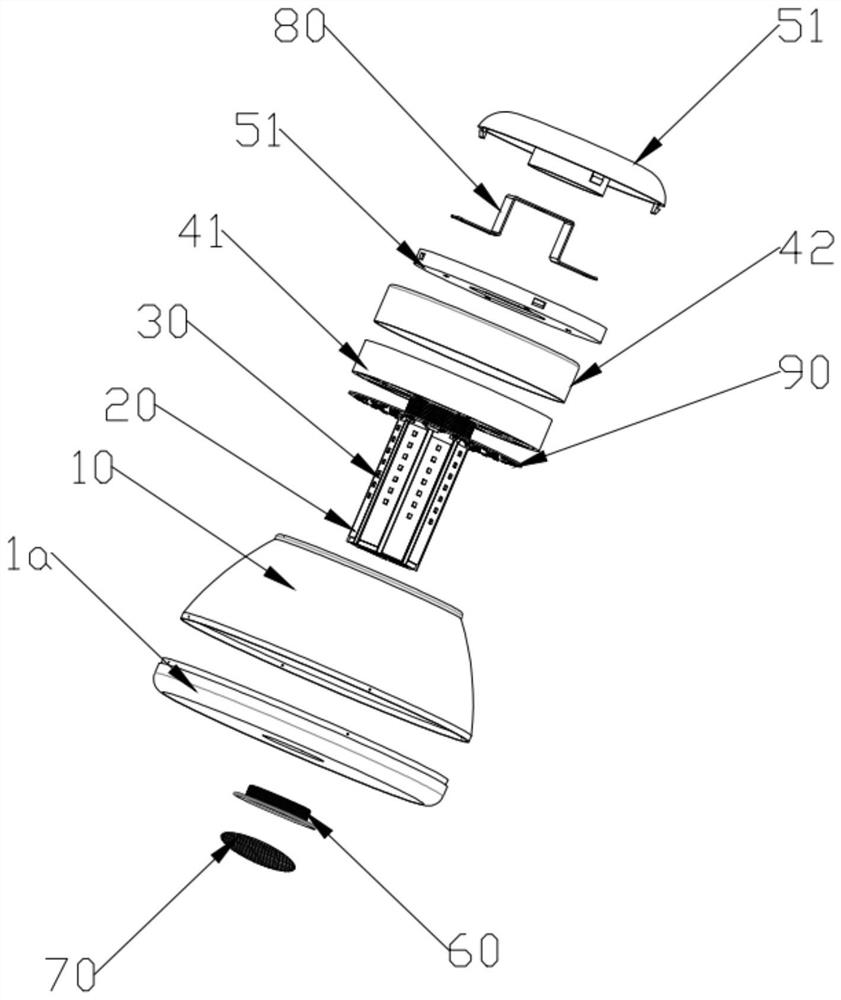

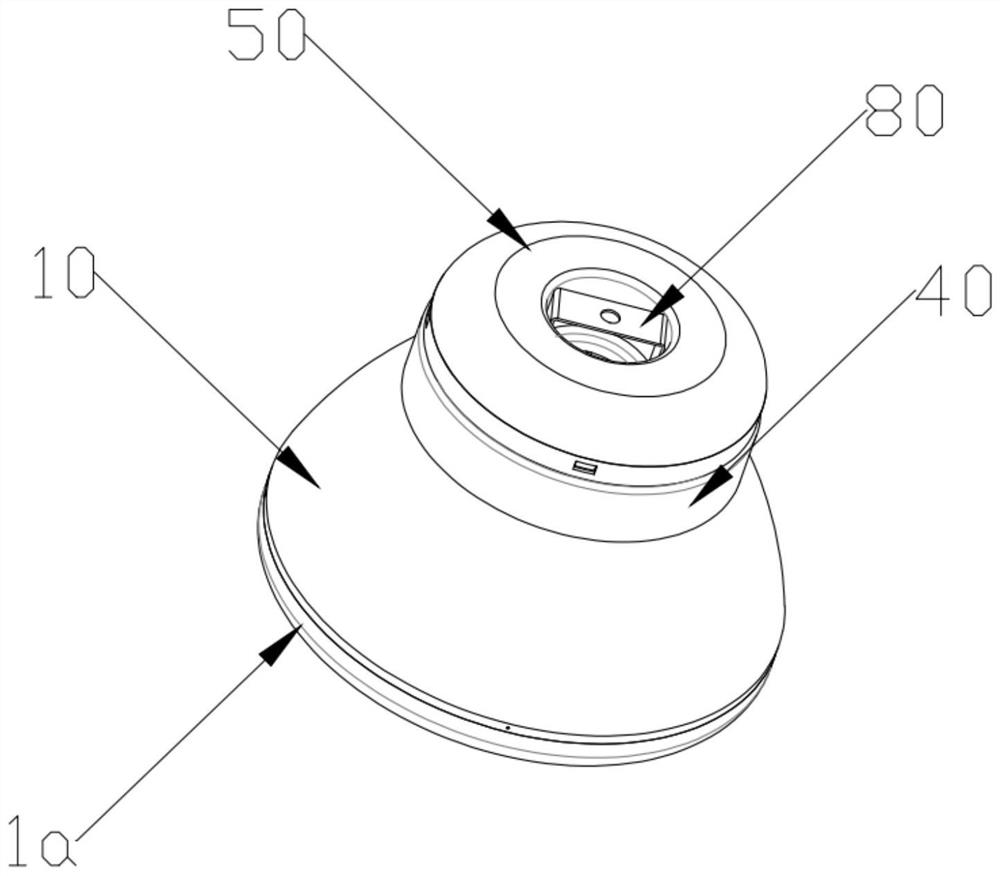

High-power LED bulb lamp

PendingCN112648543AEasy to identify working statusAvoid affecting intensityFouling preventionElectric circuit arrangementsMechanical engineeringOptics

The invention relates to the field of bulb lamps, and discloses a high-power LED bulb lamp. The bulb lamp comprises a reflector, a central through pipe is arranged in the reflector, a first light-emitting assembly is slidably arranged on the outer side wall of the central through pipe, a heat dissipation assembly is connected to the top of the central through pipe, a sensing assembly is arranged at the top of the heat dissipation assembly, a locking head is connected to the bottom of the central through pipe, and a detachable filter screen is arranged at the bottom of the locking head. The first light-emitting assembly of the bulb lamp can move on the outer side wall of the center through pipe, and focusing change of lower light is achieved; by arranging the sensing assembly, the temperature of the air outlet of the bulb lamp can be sensed in time, and the working state of the bulb lamp is judged; by arranging the detachable filter screen at the bottom of the bulb lamp, large-particle matter in air is filtered out, and dust is prevented from attaching to the bulb to affect the intensity of light; and a protruding block is arranged on the inner side wall of the center through pipe, heat generated by the first light-emitting assembly is transmitted to a radiator in the first time, and the situation that the first light-emitting assembly is burnt out due to the too high temperature is avoided.

Owner:中山市元登系统照明工业有限公司

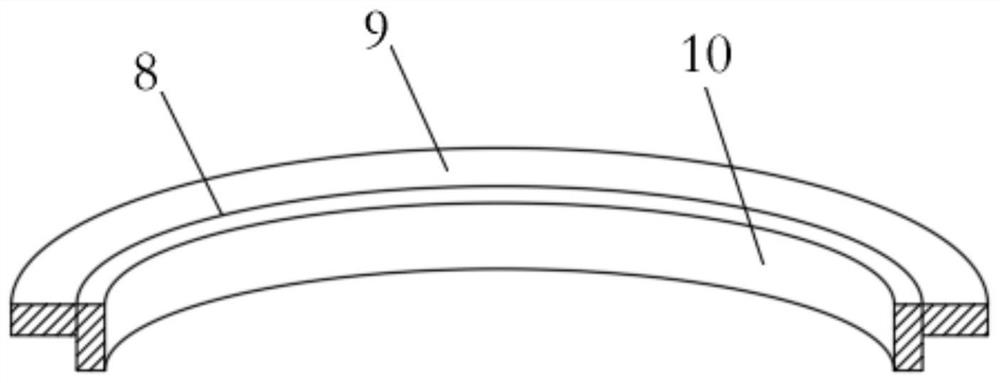

Anti-rust fastener for expansion bolt

ActiveCN111637125ARealize external waterproof functionAchieve internal rust protectionDowelsFastener

The invention discloses an anti-rust fastener for an expansion bolt. The anti-rust fastener for the expansion bolt comprises a self-tapping nut, an annular curved surface groove is formed in the position where the front end surface of the self-tapping nut is closed to a middle position, a flat ring platform groove is formed in the position where the front end surface of the self-tapping nut is closed to the middle position of the curved surface groove, a screw rail hole is formed in the middle position of the self-tapping nut, and a spiral rail is formed in the inner side wall of the self-tapping nut. The anti-rust fastener can realize sealing an interface of the annular curved surface groove, the accumulation of water vapor at the interface can be effectively avoided, local corrosion phenomenon is prevented, the water vapor is prevented from entering into a sleeve pipe main body, the internal anti-rust of the fastener is realized, the interior of the fastener is ensured to be dry, thelocal anti-corrosion function is realized, buffering is provided for the squeezing force between a bolt bar head and a sleeve pipe main body, and convenience is provided to workers to disassemble thefastener.

Owner:嘉善伟悦紧固件有限公司

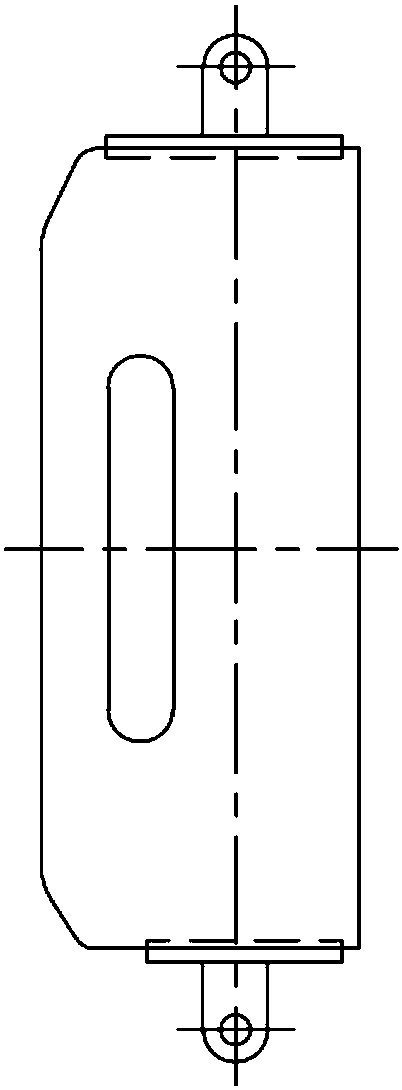

Simple safety valve shield for stand column

The invention discloses a simple safety valve shield for a stand column. The simple safety valve shield comprises a thin-wall steel sheet groove shaped structure with three sides enclosed and one sideopen; the upper end of the groove structure is sealed and the lower end of the groove structure is opened; corresponding small holes are formed in opposite lateral sides of the groove structure; andthe small holes are provided with cotter pins or other fixing pieces in a penetrating mode. When the safety valve is mounted at the stand column, the shield is fastened; and the small holes are penetrated by the fixing pieces and the shield is fixed. The fixing pieces are mounted under a valve seat of the safety valve. The shield is free of a lug plate. The structure is simple and the outline is smooth; only the cotter pins are needed to fix between the shield and the stand column, installation and disassembly are convenient; the stand column is free of welding a valve pad, and therefore the cost is lowered and influence on a cylinder intensity is avoided.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

Glass wool for building and partition plate containing glass wool

The invention provides glass wool for buildings and a partition plate containing the glass wool. The glass wool is prepared through the following steps: step S1, dipping a glass wool raw material with acid, and then conducting cleaning to obtain acid-leached glass wool; S2, dispersing nano-TiO2 in a solvent so as to obtain a nano-TiO2 dispersion liquid; S3, dipping the acid-leached glass wool in the nano-TiO2 dispersion liquid, and conducting drying to obtain pretreated glass wool; and S4, impregnating the pretreated glass wool with a silane coupling agent solvent, and conducting drying to obtain the modified glass wool. Compared with the prior art, the invention has the beneficial effects that the glass wool is subjected to acid corrosion to increase the hydrophilicity of the glass wool; then the glass wool is soaked in the titanium dioxide dispersion liquid, so the loading capacity of titanium dioxide is increased, and the ageing resistance of the superfine glass wool is improved; and after the nano-TiO2 is deposited, the silane coupling agent is finally used for sealing layer modification, so moisture resistance is prevented from being reduced after the glass wool is corroded in an early stage.

Owner:HUBEI JIA FU DA ENERGY SAVING TECH CO LTD

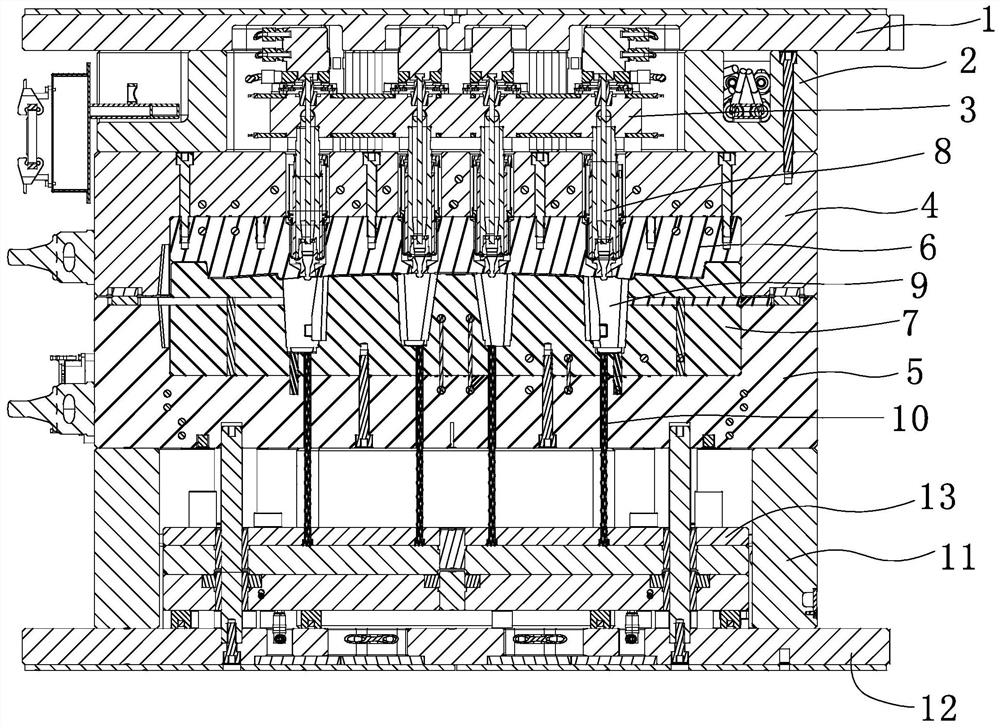

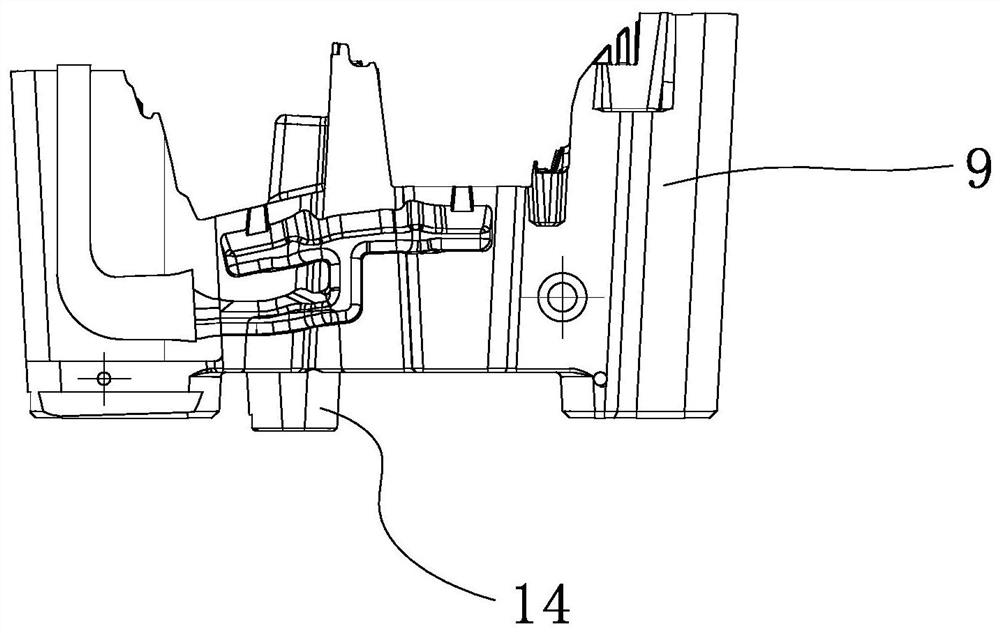

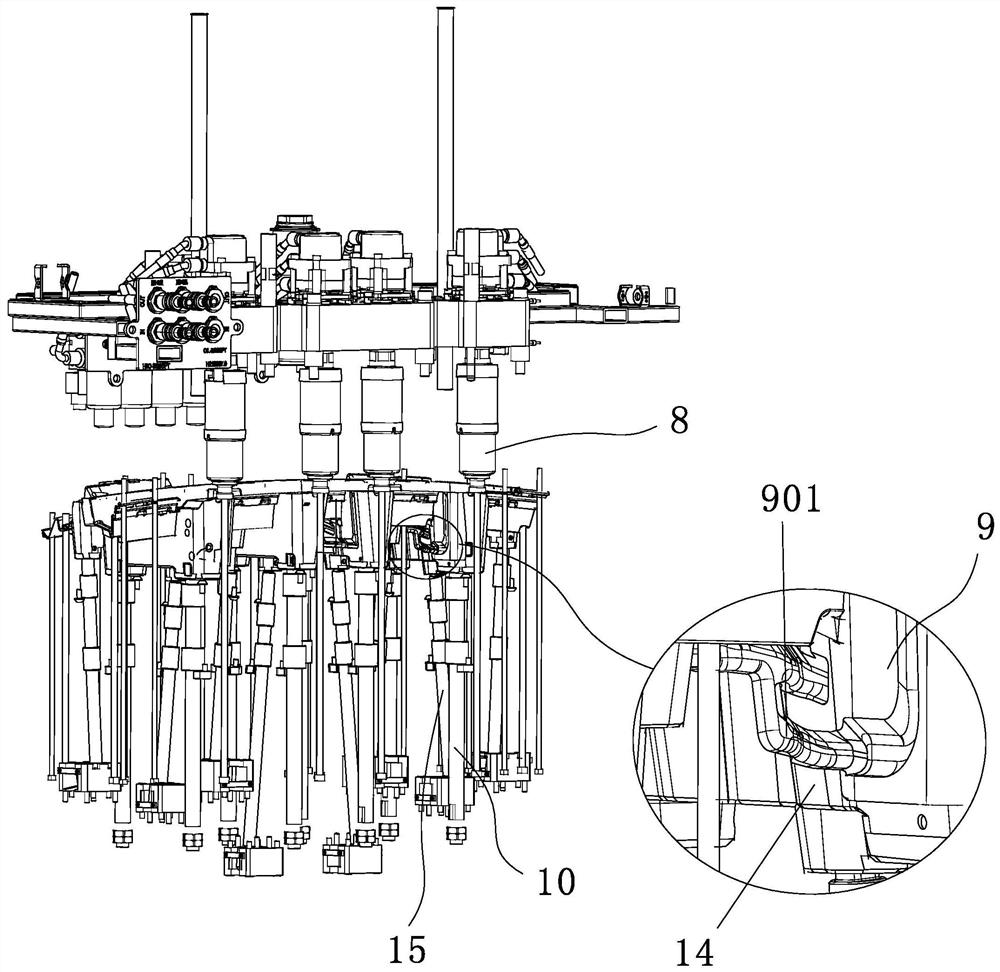

Multi-point straight ejection glue feeding mechanism of injection mold

InactiveCN113858553APosition is easy to controlImprove aestheticsCoatingsHot runnerMechanical engineering

The invention discloses a multi-point straight ejection glue feeding mechanism of an injection mold. The multi-point straight ejection glue feeding mechanism comprises an upper compound plate and a lower compound plate, and a hot runner plate is arranged on the upper compound plate. The multi-point straight ejection glue feeding mechanism further comprises multiple straight ejection glue feeding assemblies, each straight ejection glue feeding assembly comprises a straight ejection block and an inclined ejection block, a sprue runner used for feeding glue to the bottom of a product is arranged on each straight ejection block, and the inclined ejection blocks are arranged on the straight ejection blocks. According to the multi-point straight ejection glue feeding mechanism for the injection mold, a better weld line is formed, the product attractiveness is improved, the position of the weld line is convenient to control, and the product strength is prevented from being influenced.

Owner:ZHEJIANG KAIHUA MOLDS

Header with elliptical necking end socket and manufacturing method thereof

PendingCN112302789AAvoid cumbersome proceduresInhibit sheddingMachines/enginesMetallic materialsStructural engineering

The invention discloses a header with an elliptical necking end socket and a manufacturing method thereof, and belongs to the technical field of metal material machining. An oval necking end socket isformed at one end of a header barrel in a hot spinning mode, a necking hole is reserved in the oval necking end socket and connected with a first pipe connector, and a plurality of second pipe connectors are connected onto the header barrel. According to the header with the elliptical necking end socket and the manufacturing method thereof provided by the invention, tedious procedures such as endsocket machining and groove welding are avoided, and the end socket and the header barrel do not need to be welded in quantity, so that potential quality hazards caused by welding are avoided, the possibility that the header end cover falls off is avoided, and the safety and the reliability in operating a thermal power generating unit are improved. Meanwhile, the necking hole left by the hot spinning process is connected with the first pipe connector, and the hole generated by the hot spinning process is utilized, so that the manpower and the material resources for opening the hole are saved,the production efficiency is improved, and the application prospect is good.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

A kind of soybean meal adhesive for blockboard and preparation method thereof

ActiveCN111675998BHigh molecular weightLow viscosityNon-macromolecular adhesive additivesProtein adhesivesBiotechnologyCalcium biphosphate

The invention discloses a soybean meal adhesive for blockboards and a preparation method thereof. The adhesive comprises the following components in parts by mass: 22-26 parts of soybean meal powder, 86 parts of dispersant, 2-3 parts of trypsin, 1-2 parts of composite viscosity modifier, 2-3 parts of branched polymer cross-linking agent, 0.04-0.04 part of calcium phosphate, the preparation method comprises the following steps: K1. plasma treatment of soybean meal powder under nitrogen atmosphere, then adding chlorinated Calcium and dispersant, after ultrasonic treatment, add trypsin and treat at 50-60°C for 20 minutes, add phosphoric acid after cooling, and stir evenly to obtain the first mixture; K2. Add calcium phosphate and branched polymer cross-linking agent to the first After the mixture is evenly stirred, add a compound viscosity regulator and adjust the pH to 9.0 to obtain a soybean meal adhesive for blockboards, which has good water-resistant bonding performance and ensures the practical performance of the adhesive and the durability of blockboards. sex.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

Anti-rust fastener for expansion bolt

ActiveCN111637125BRealize external waterproof functionAchieve internal rust protectionDowelsWater vaporClassical mechanics

Owner:嘉善伟悦紧固件有限公司

Road fence with breaking structure

InactiveCN106758979AFast pushEasy to transformRoadway safety arrangementsAerospace engineeringVertical bar

Owner:赵永潮

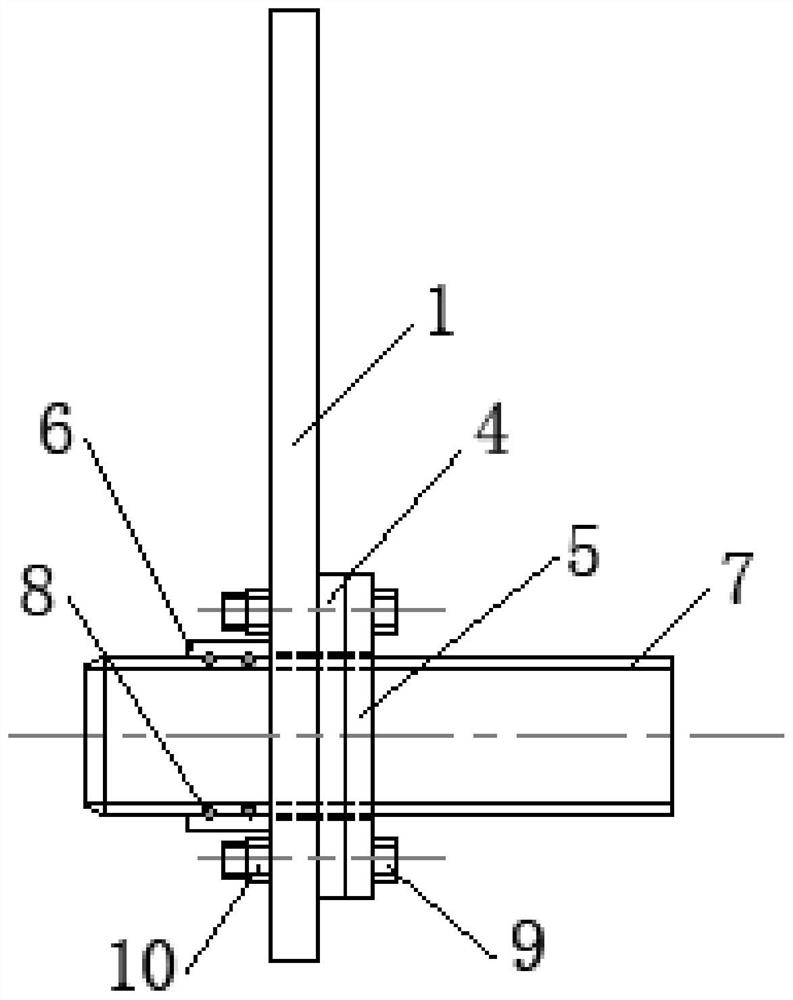

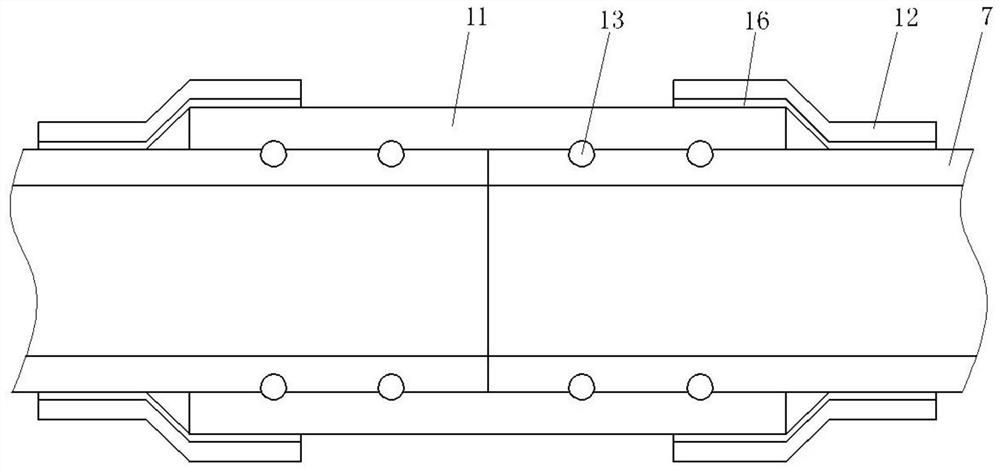

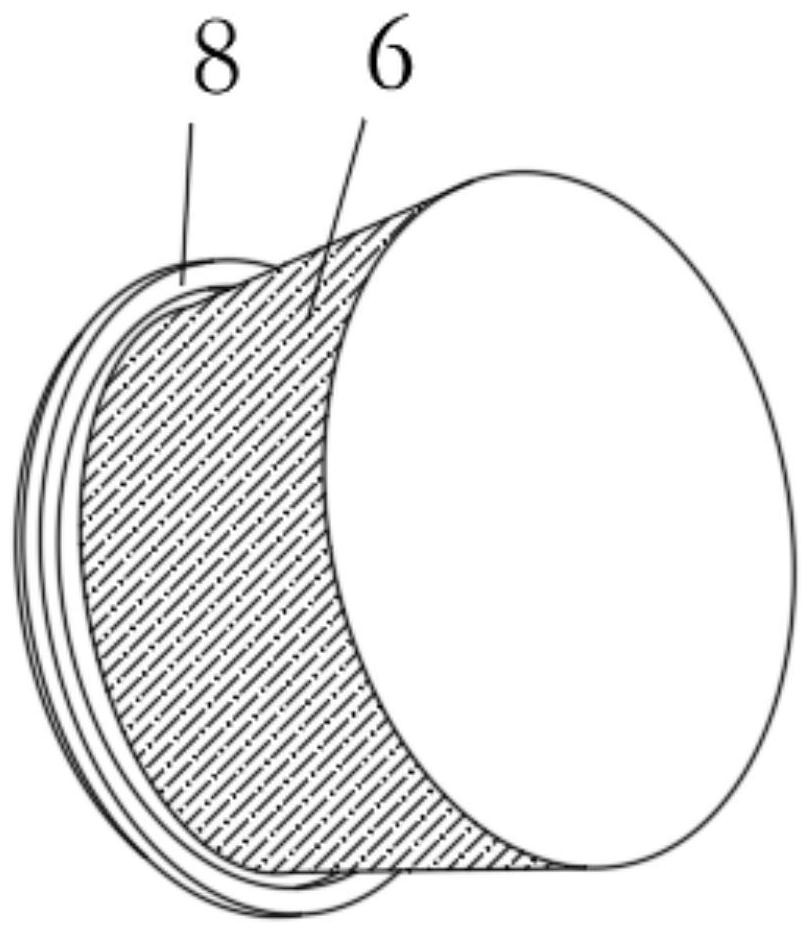

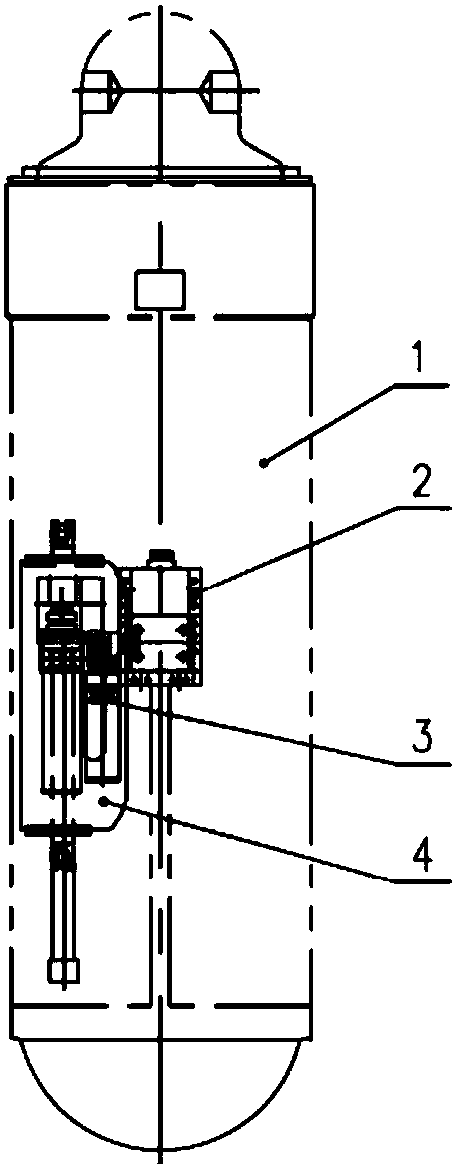

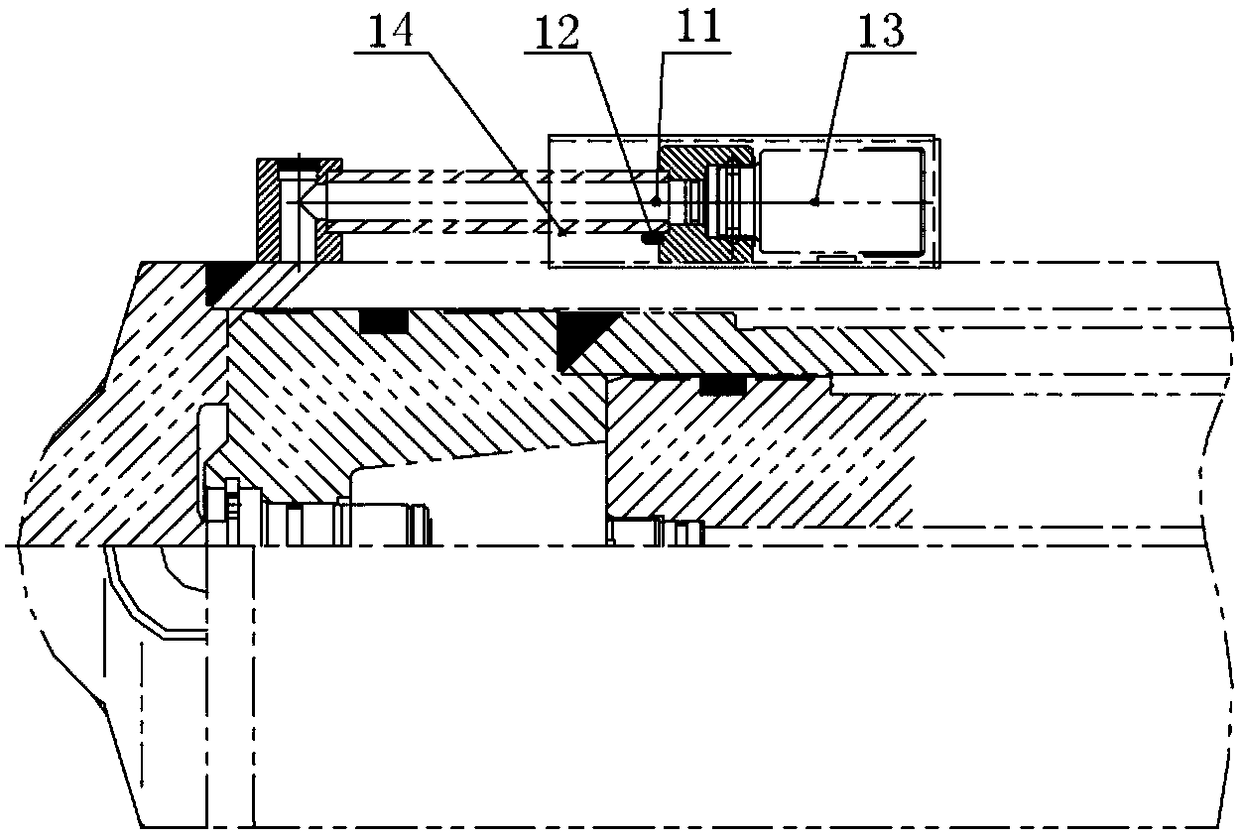

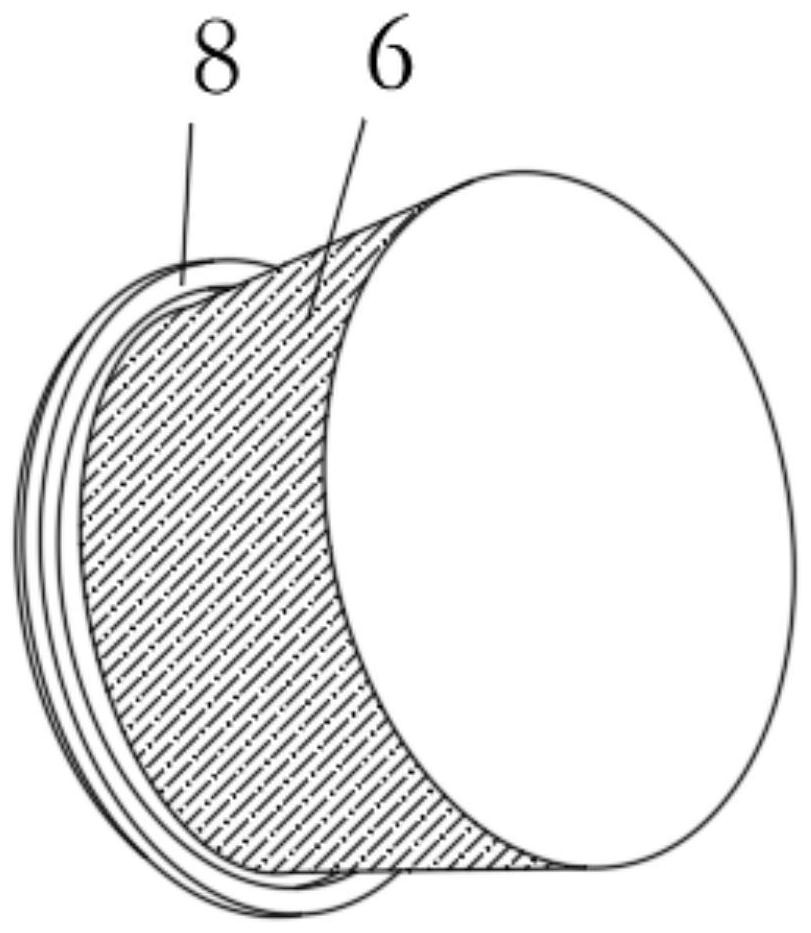

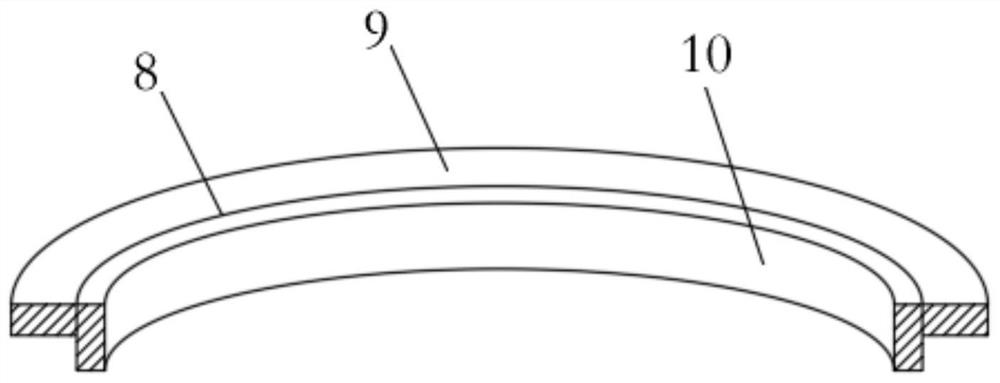

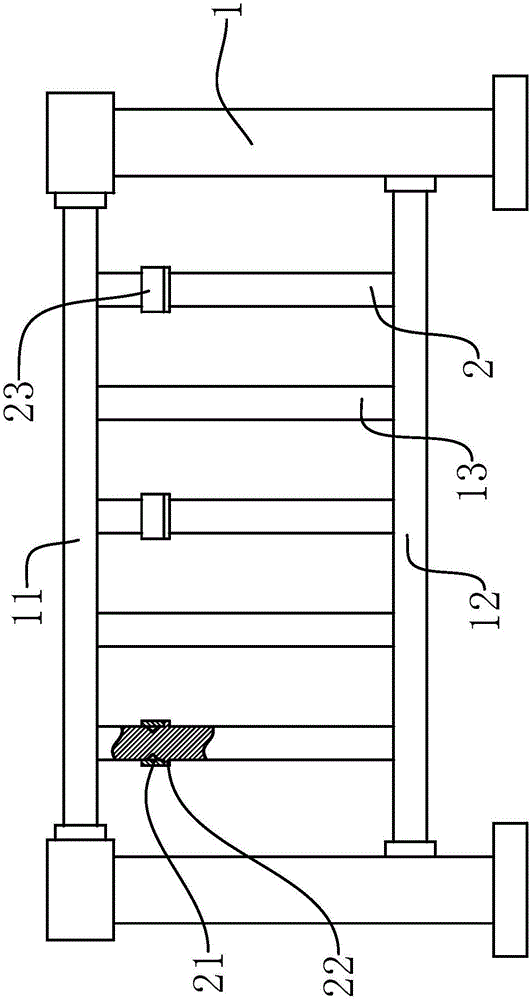

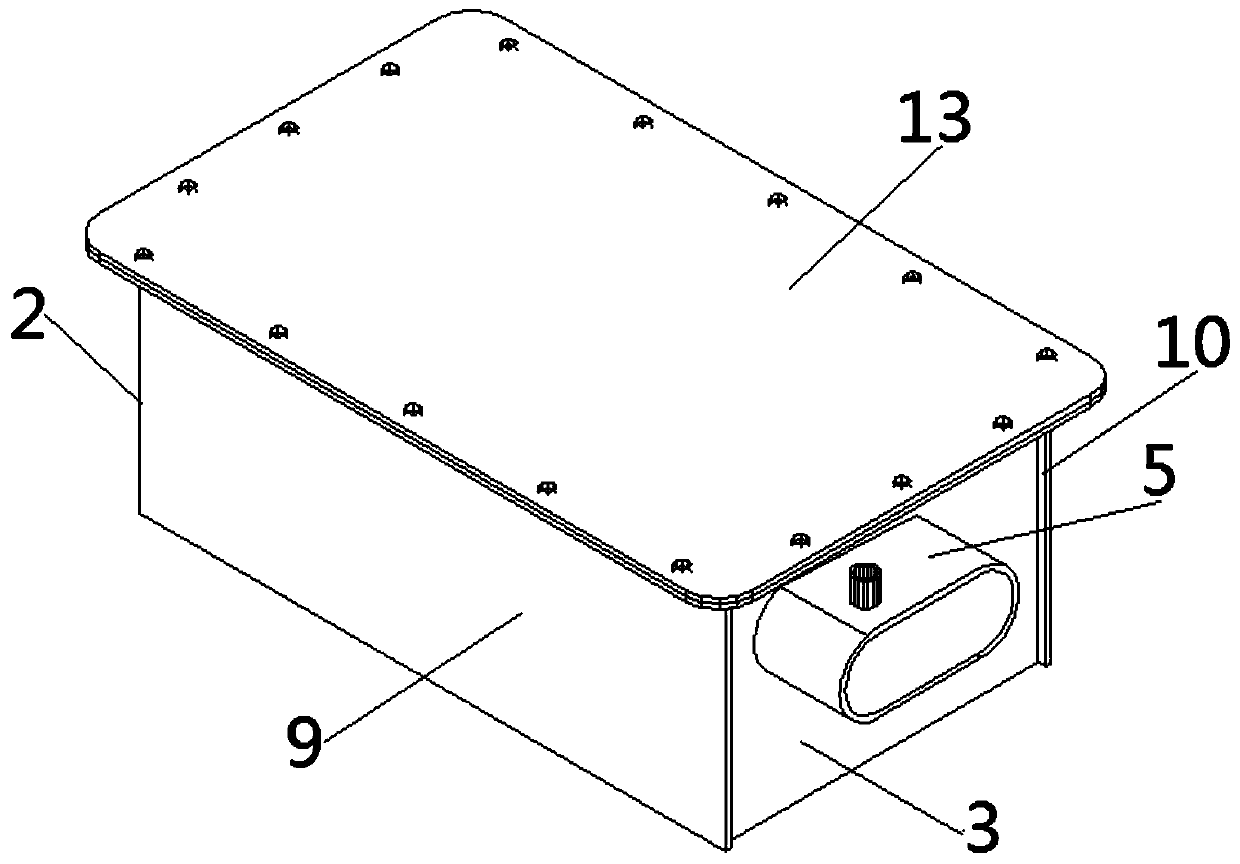

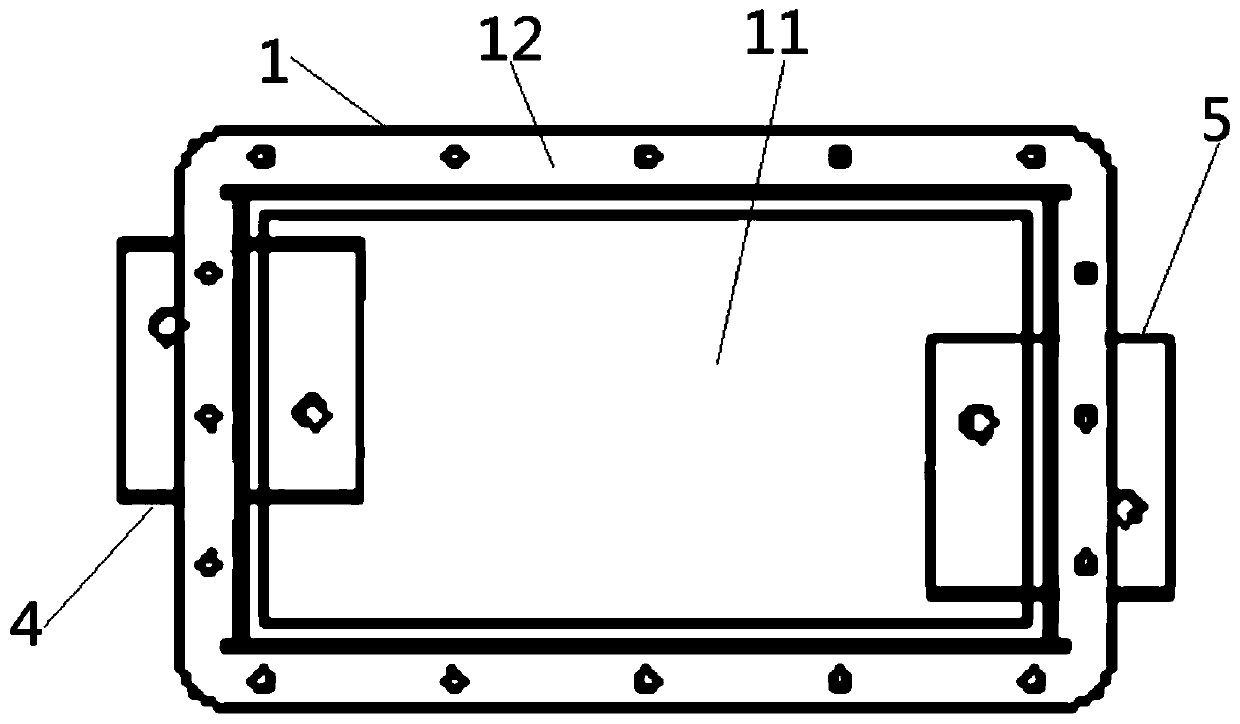

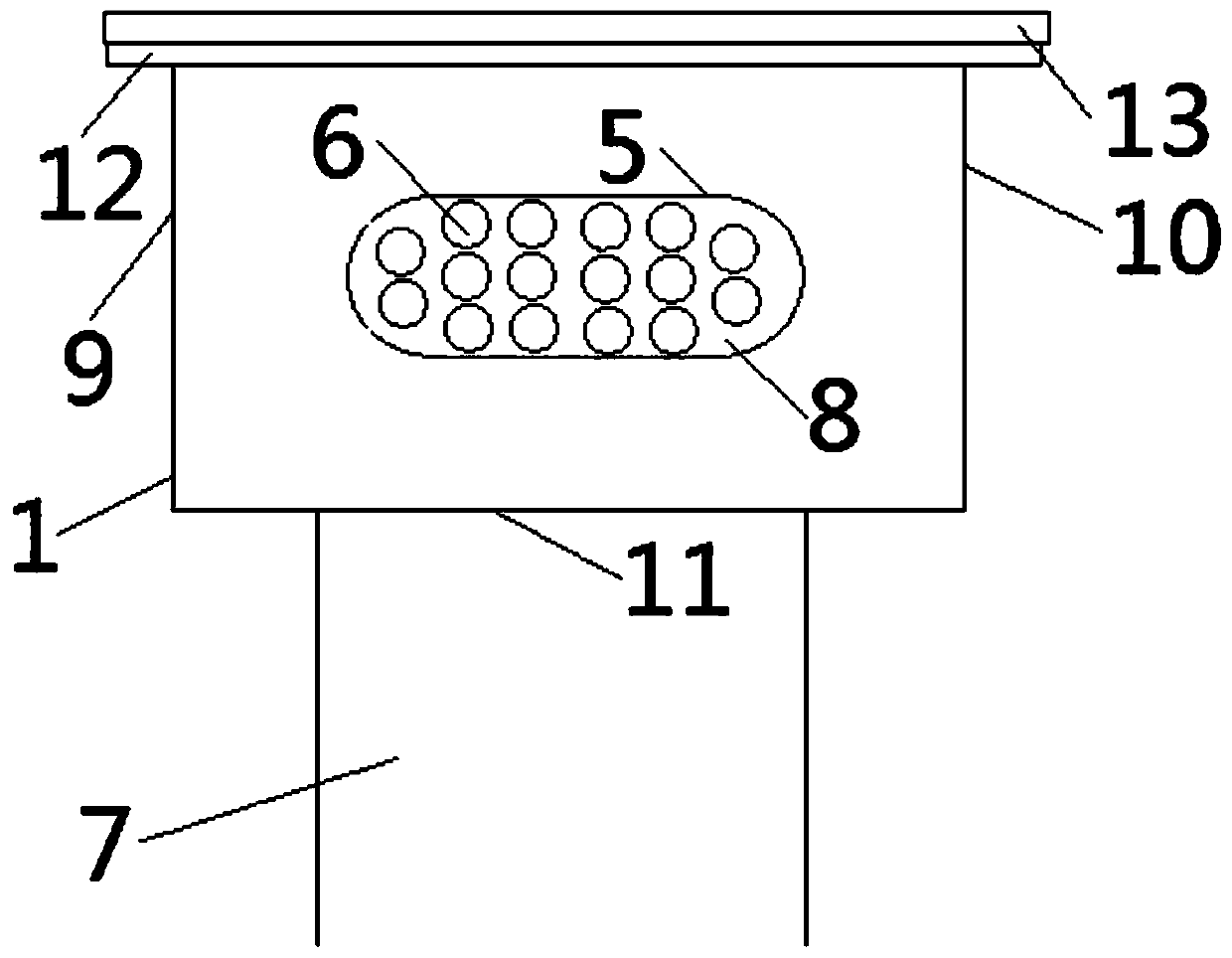

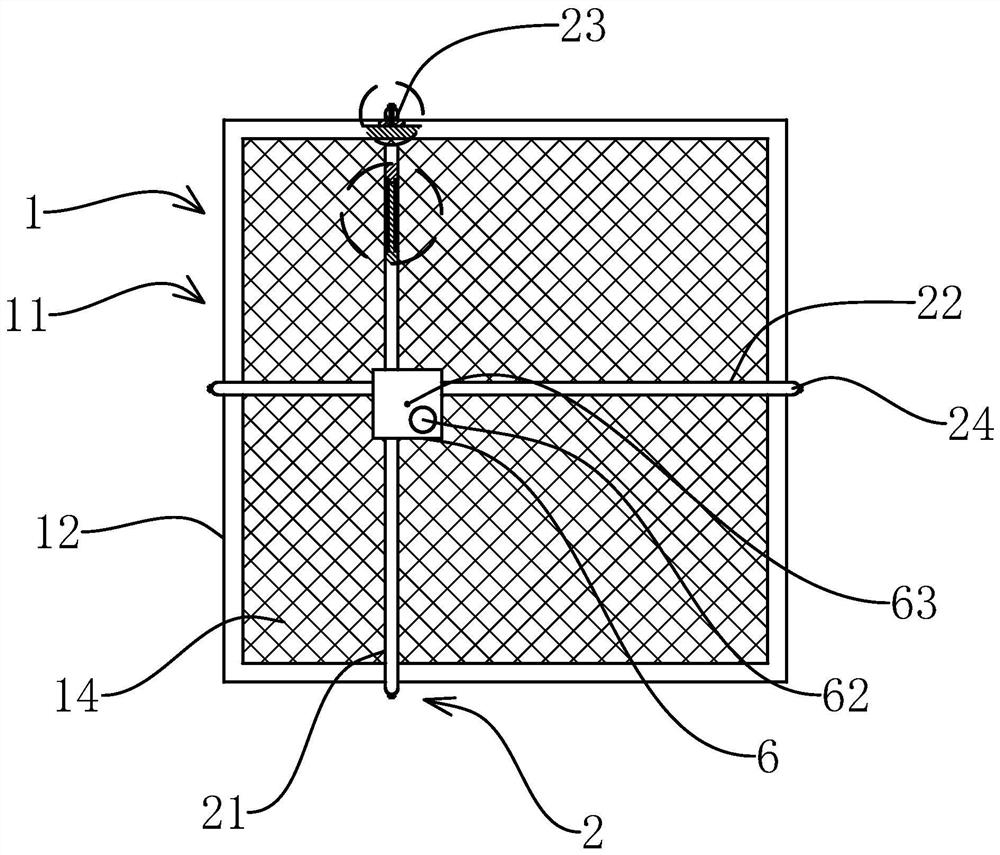

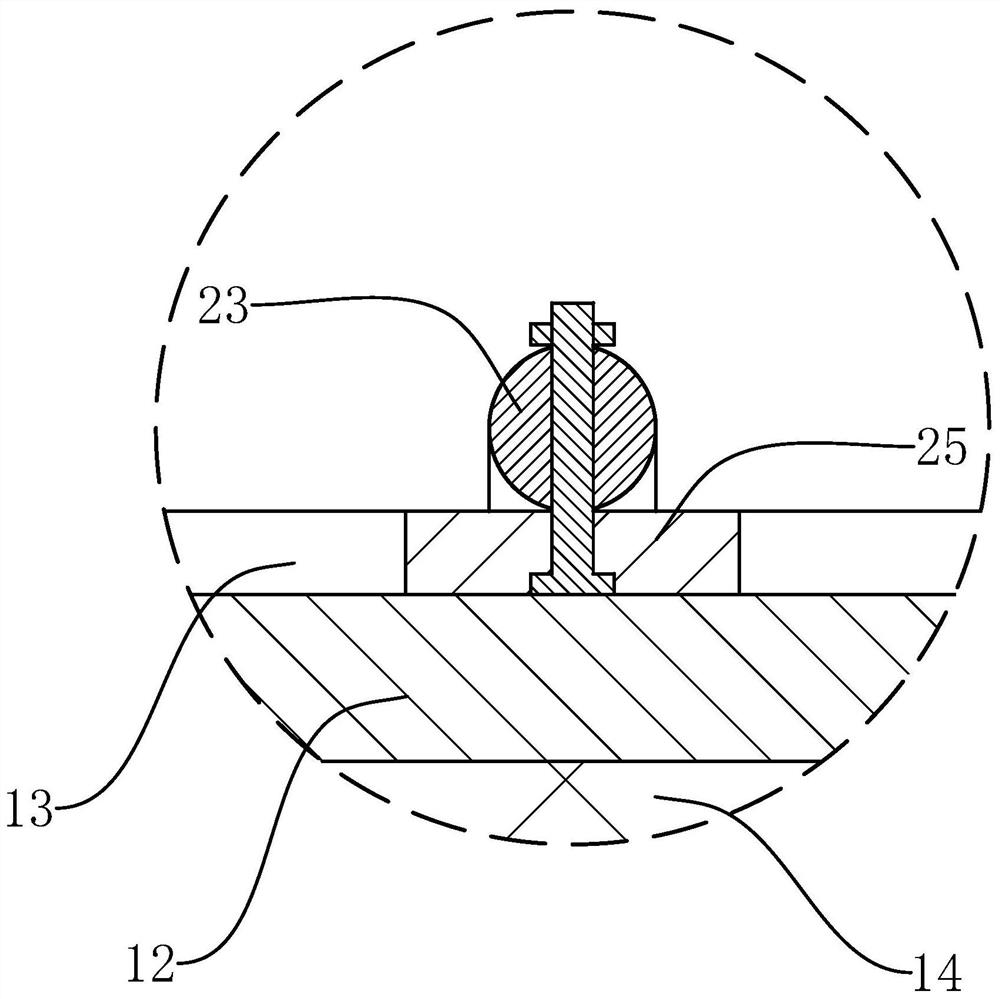

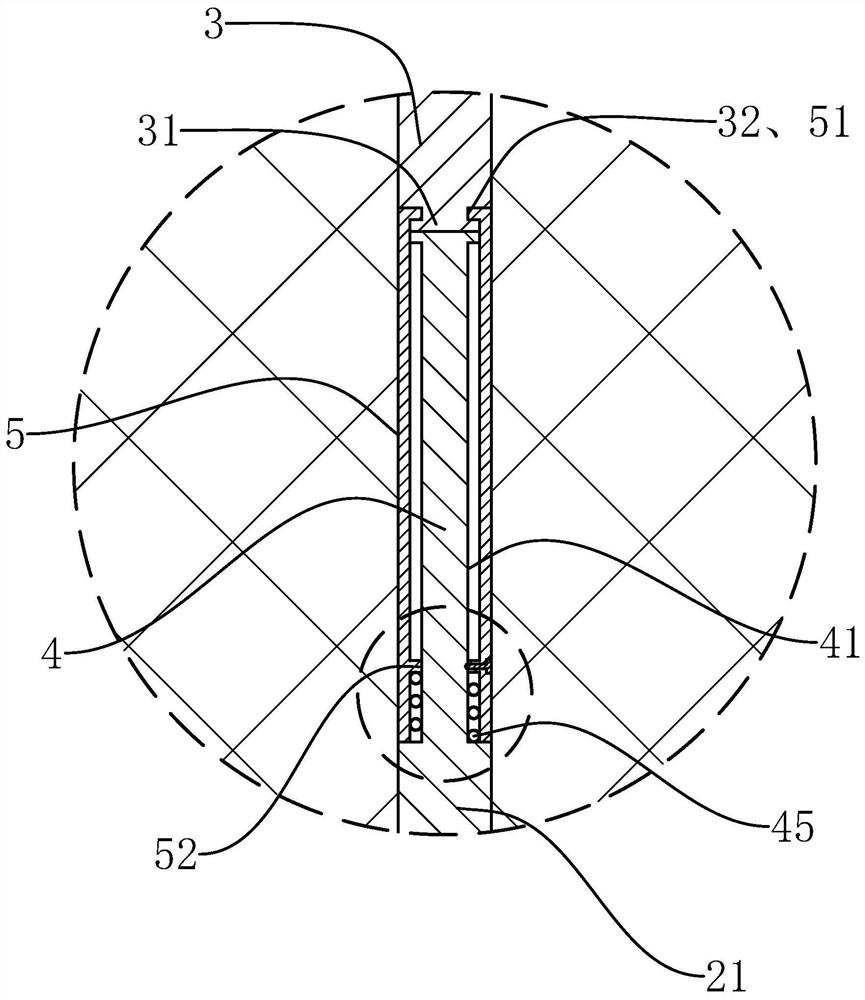

Ship water-penetrating closed cabin pipe bundle structure

ActiveCN110752566AImprove the efficiency of mobile deploymentReliable sealingElectrical apparatusWater tightnessBulk cargo

The invention provides a ship water-penetrating closed cabin pipe bundle structure applied to the technical field of various ships such as bulk cargo, containers and roll-on-roll-off. A front cabin-penetrating pipe fitting (4) is arranged on a front box body coaming (2) of a pipe bundle adapter box body (1) of the ship water-penetrating closed cabin pipe bundle structure, wherein a rear cabin-penetrating pipe fitting (5) is arranged on a rear box body coaming (3); a plurality of pipe fittings (6) of a pipe bundle penetrate through the front cabin-penetrating pipe fitting (4) and the rear cabin-penetrating pipe fitting (5) simultaneously; gaps between the pipe fittings (6) of the pipe bundle positioned on the front cabin-penetrating pipe fitting (4) or the rear cabin-penetrating pipe fitting (5) are filled with sealing blocking materials (8); and the pipe bundle adapter box body (1) is welded to the upper portion of a cabin wall (7). According to the ship water-penetrating closed cabinpipe bundle structure, the pipe fittings of the pipe bundle can be arranged conveniently and rapidly, and the pipe fittings can be arranged and moved quite conveniently and rapidly; meanwhile, the water tightness of the pipe bundle is effectively guaranteed, the strength and the sealing performance of the penetrating cabin wall cannot be damaged, and the labor cost and the material cost are reduced.

Owner:WUHU SHIPYARD CO LTD

A kind of pump concrete and preparation method thereof

ActiveCN112851239BIncrease elasticityAvoid easy cloggingCement mixing apparatusFiberMining engineering

The application relates to the field of concrete, and specifically discloses a pumping concrete and a preparation method thereof; the pumping concrete is made of raw materials containing the following parts by weight: 280-400 parts of cement, 50-70 parts of fly ash, mineral powder 80‑100 parts, 585‑680 parts of river sand, 1050‑1110 parts of coated gravel, 140‑155 parts of water, 7‑10.5 parts of admixture, 8‑12 parts of modified composite fiber; the modified composite fiber is composed of bamboo fiber and It is made by mixing polyurethane fibers; its preparation method is: take coated crushed stone, modified composite fiber, and water and mix and stir to make a mixture; weigh cement, fly ash, mineral powder, river sand, The admixture is added to the mixture prepared by S1, and the concrete mixture is prepared after stirring and mixing, pumped and poured into the mold, and the pumped concrete is made after curing; it has the function of making the pumped concrete not easy to block the pipeline during pumping , and has the advantage of higher strength after curing.

Owner:广州市粤砼混凝土有限公司

Lay-up method

The invention provides a hand lay-up molding method. The hand lay-up molding method comprises the following steps of S01: laying a base layer; S02: laying a glass fiber cloth layer on the base layer, and coating resin on the glass fiber cloth layer in a rolling manner, so as to enable the resin to permeate uniformly into the glass fiber cloth layer; S03: scraping the excessive resin after the step S02; S04: laying the glass fiber cloth layer in the step S03 to a position needing hand lay-up, then compacting, and finally tearing off the base layer.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

Heat preservation method for welding spots in welding process of steel pipe

InactiveCN104128699ADoes not affect the cleaning effectReduce lossWelding accessoriesWeld seamEngineering

Owner:CHENGDU XINGBODA PRECISION MACHINERY

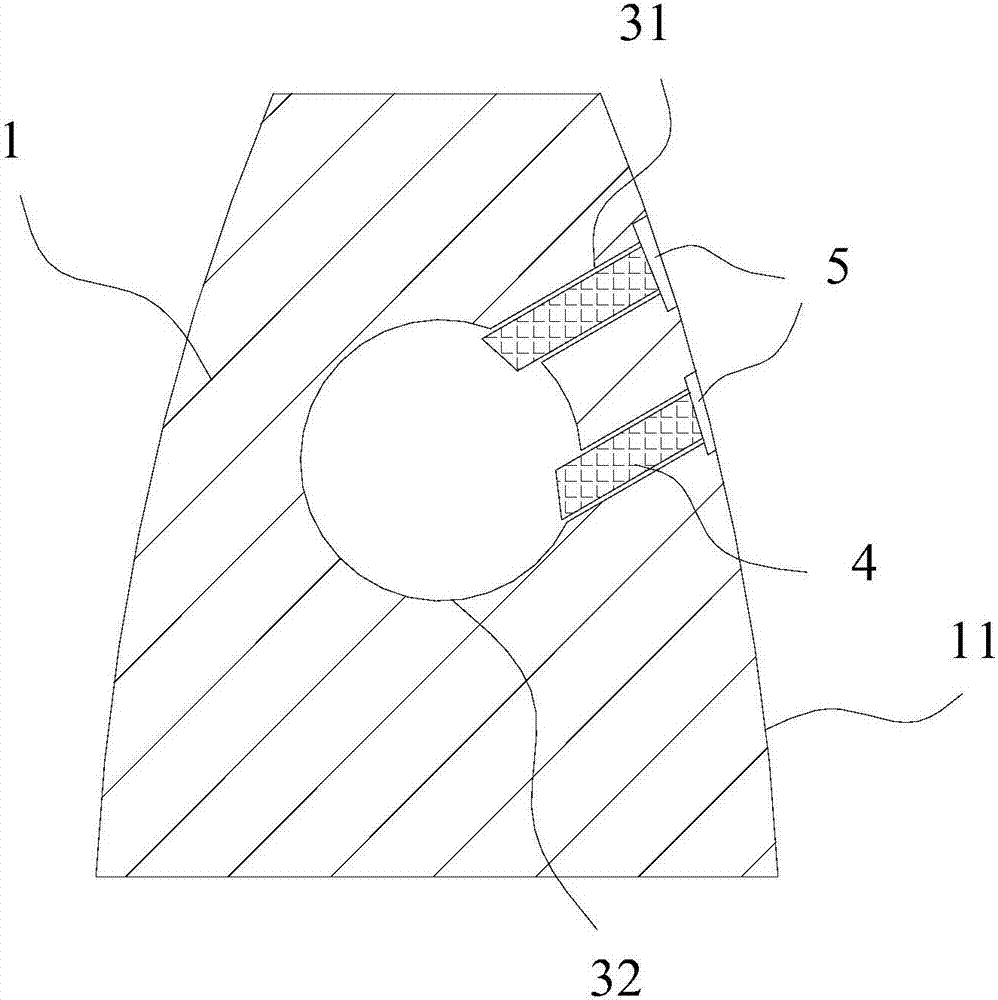

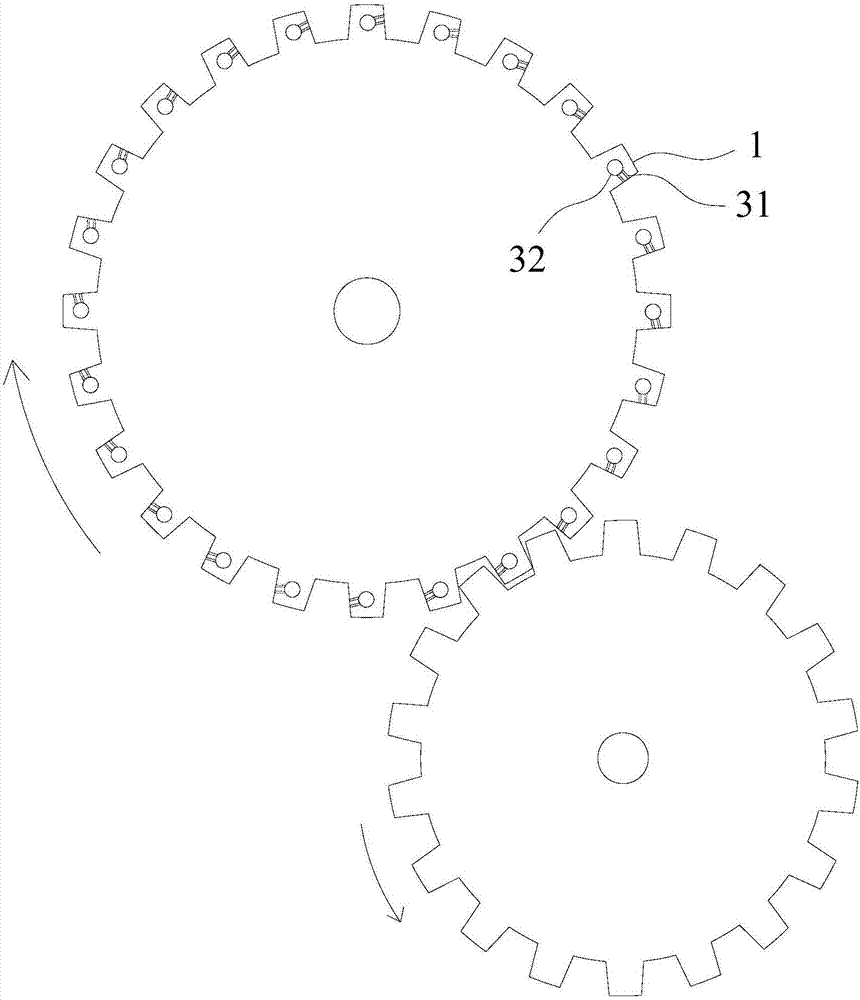

Novel internal self-lubricating gear

PendingCN107061693AReduce wearExtended service lifeGear lubrication/coolingPortable liftingReduction driveGear wheel

The invention relates to a novel internal self-lubricating gear which comprises a plurality of gear teeth. Each gear tooth is internally provided with a cavity. The engagement area of each gear tooth is provided with a plurality of first holes. A body is provided with one or more second holes. The first holes and the second holes all communicate with the cavities. The second holes are provided with one-way valves. By adoption of the novel internal self-lubricating gear, the engagement areas of the gear tooth can be automatically and continuously lubricated, the lubricating effect is improved, the lubrication area is wide, abrasion to the gear teeth is reduced, the service life of the gear is prolonged, reliability and safety of gear working are improved, the safety problem that lubricating oil is inconvenient to add during work of the gear is solved, lubricating oil waste is reduced, lubricating oil leakage caused by an oil bath mode is avoided, cost is saved, the structure is simple, machining is convenient, and the gear is particularly suitable for a low-speed heavy-load large reducer.

Owner:CHENGDU TECHCAL UNIV

Base-band chip heat-dispersion structure and mobile terminal

ActiveCN105118813AAvoid affecting intensityRealize installation positioningSemiconductor/solid-state device detailsSolid-state devicesComputer terminalEngineering

The invention discloses a base-band chip heat-dispersion structure which comprises a circuit board, a base-band chip and a thermal conductive heat pipe, wherein the base-band chip and the heat pipe are respectively arranged on the two opposite surfaces of the circuit board, the heat pipe is attached and fixed to the circuit board, the heat pipe has a heat absorption end facing the base-band chip, the base-band chip and the heat pipe are respectively arranged on two opposite surfaces of the circuit board, and the heat absorption end of the heat pipe faces the base-band chip. Heat of the base-band chip can be directly conducted to the heat absorption end of the heat pipe. The thermal resistance is relatively low, heat transfer efficiency is high, and the heat-dispersion performance is improved. The heat pipe is fixed on the circuit board and integrated with the circuit board to install and position the heat pipe, and a groove for installing and positioning the heat pipe does not have to be arranged in other structures, such as a middle frame, of the mobile terminal. The strength of other structural member of the mobile terminal may not be affected. The invention further discloses a mobile terminal employing the base-band chip heat-dispersion structure.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

An impact-resistant filter net frame and its assembly and disassembly method

The invention provides an impact-resistant filter net frame and an assembly and disassembly method thereof, which belong to the field of water purifiers. It solves the problem that the existing filter screen is easily deformed by impact. The impact-resistant filter screen frame includes a filter frame, which includes a frame and a filter net, and also includes a support frame, two vertical support rods and a horizontal support rod of the support frame, and two vertical curved rods and horizontal curved rods, and a vertical support rod The top end is connected with the vertical bending rod through a vertical telescopic adjustable mechanism, and also includes a front support seat and a rear support seat. The front support seat is provided with two front support holes, and the rear support seat is provided with two rear support holes. The support rod and a horizontal support rod are passed through the two front support holes, the other vertical support rod and the other horizontal support rod are passed through the two rear support holes, and the front support seat is equipped with a In the supporting part of the head, alignment grooves are arranged on the outside of the four frame bars, and alignment blocks are fixed on the opposite side of the two vertical bending bars and the opposite side of the two transverse bending bars. The filter net frame has high impact resistance.

Owner:WENZHOU BAIYA MASCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com