Pump concrete and preparation method thereof

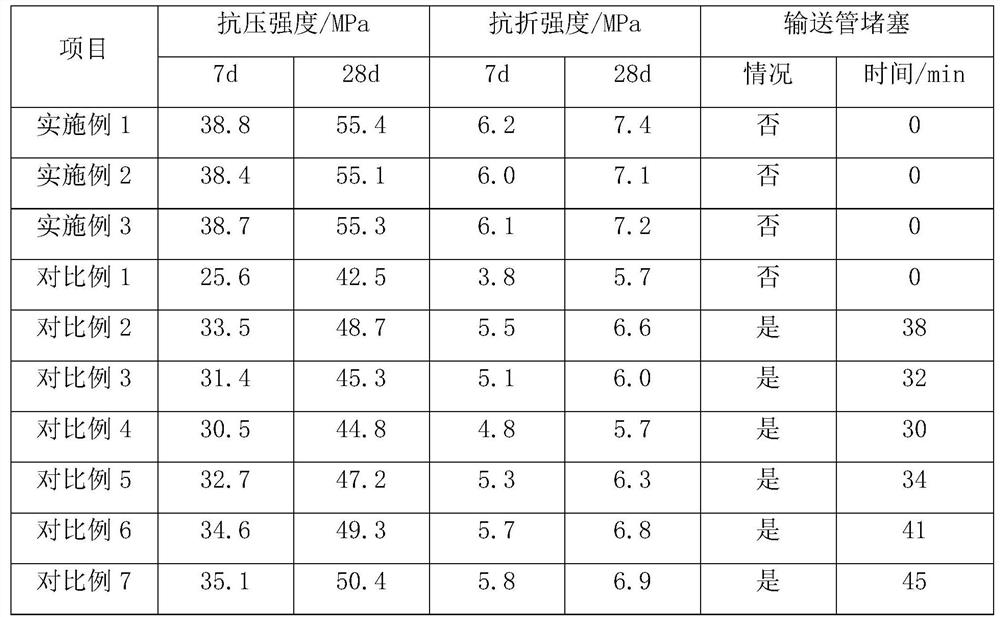

A technology for pumping concrete and composite fibers, which is applied in the field of concrete, and can solve problems such as blocked pipes, gravel fluidity, poor workability, and blockages, and achieves high strength, is not easy to block pipes, and improves strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Preparation example of coated crushed stone

[0042] The rosin in the following raw materials was purchased from the first-grade rosin produced by Jinan Yingshun Chemical Co., Ltd.; the absolute ethanol was purchased from Shandong Yiwei’an Chemical Technology Co., Ltd., with a content of 99.5%; the epoxy resin was purchased from Huizhou Sandao New Material Co., Ltd. The produced epoxy resin ab glue, model SD811; the sodium hydroxide was purchased from the granular alkali produced by Cangzhou Bangzhide Chemical Products Co., Ltd.; For ordinary commercially available.

preparation example 1

[0043] Preparation Example 1: Coated gravel is prepared by the following method:

[0044] Ⅰ Weigh 4.5kg of rosin, crush it to a particle size of 15-20mm, mix the rosin with 82kg of absolute ethanol, heat up to 80°C, stir at a speed of 850r / min, and continuously add absolute ethanol to 82kg during the stirring process, Stir for 22 minutes and dissolve the rosin completely to obtain a rosin mixture; weigh 0.85 kg of epoxy resin, place the epoxy resin in the rosin mixture and stir for 15 minutes at a speed of 550 r / min to obtain a mixture;

[0045] II weighed 130kg of gravel and put it in the stirring solution prepared by I, stirred it at a speed of 820r / min for 10 minutes, and dried it at 60°C for 2 hours, and the dried stirring solution solidified into a rosin film. The thickness is 2mm, put the crushed stone coated with rosin film into 160kg of spherical sodium hydroxide particles with a particle size of 3-5mm and stir at a speed of 150r / min for 20s, and take out the crushed s...

preparation example 2

[0046] Preparation example 2: The coated crushed stone is prepared by the following method:

[0047] ⅠWeigh 3kg of rosin, crush it to a particle size of 15-20mm, mix the rosin with 75kg of absolute ethanol, heat up to 75°C, stir at a speed of 850r / min, continuously add absolute ethanol to 75kg during the stirring process, and stir The rosin was completely dissolved in 25 minutes to obtain a rosin mixture; 0.5 kg of epoxy resin was weighed, and the epoxy resin was placed in the rosin mixture and stirred at a speed of 550 r / min for 15 minutes to obtain a mixture;

[0048] Ⅱ Weigh 120kg of gravel and place it in the stirring solution prepared by Ⅰ, stir it at a speed of 820r / min for 10 minutes, and dry it at 60°C for 2 hours. After drying, the stirring solution solidifies into a rosin film. The thickness is 1.5mm, put the crushed stone coated with rosin film into 150kg of spherical sodium hydroxide particles with a particle size of 3-5mm and stir at a speed of 150r / min for 10s, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com