Construction waste regeneration treatment system and treatment method thereof

A construction waste and treatment system technology, applied in construction waste recycling, recycling technology, solid waste removal, etc., can solve problems such as strength reduction, adverse effects on resources, affecting the quality and strength of recycled concrete, and improve quality. , strong practicability, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

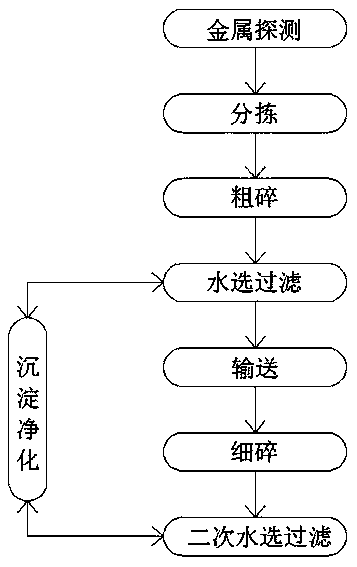

Method used

Image

Examples

Embodiment approach

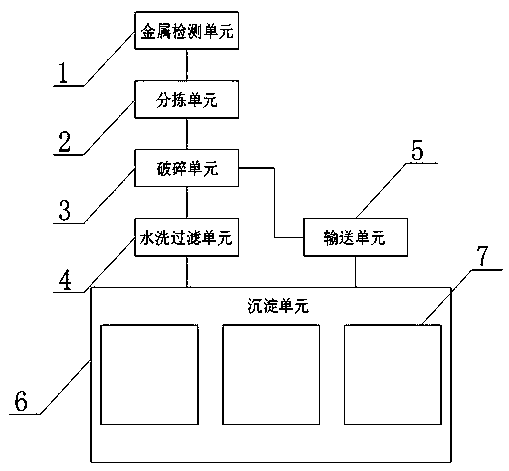

[0033] As a preferred embodiment of the present invention, the sedimentation unit 6 is composed of several sedimentation tanks 7 .

[0034] As a preferred embodiment of the present invention, the water used in the fifth step and the eighth step is purified water in the precipitation unit 6 .

[0035] In order to achieve the above object, the present invention also provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the steps of any one of the above-mentioned methods are realized.

[0036] As a preferred mode of the present invention, several electric railcars 7 can run cyclically on the circular track 1 and the circumscribed track 2 to form a closed loop, and each mechanism cooperates to produce concrete prefabricated parts, which can effectively reduce construction waste. Recycled quality, great practicality, and a small footprint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com