Steel structure beam column joint and manufacture and installation method thereof

A beam-column joint and steel structure technology, which is applied in building structure, construction, etc., can solve the problems of low construction efficiency, corrosion and rust of connecting parts, large stress on the connection parts between steel plates and beams and columns, etc. Stability, high safety and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

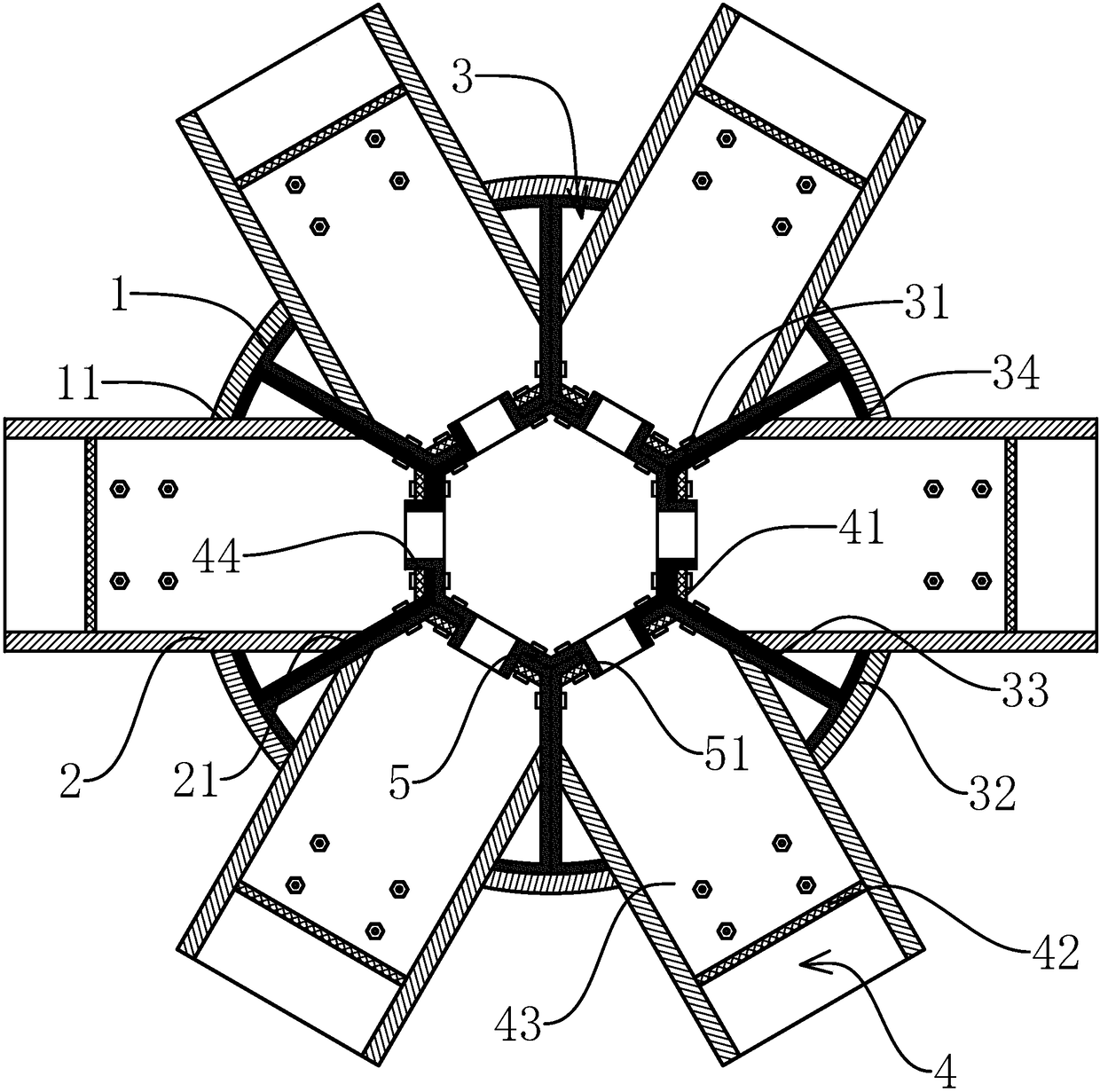

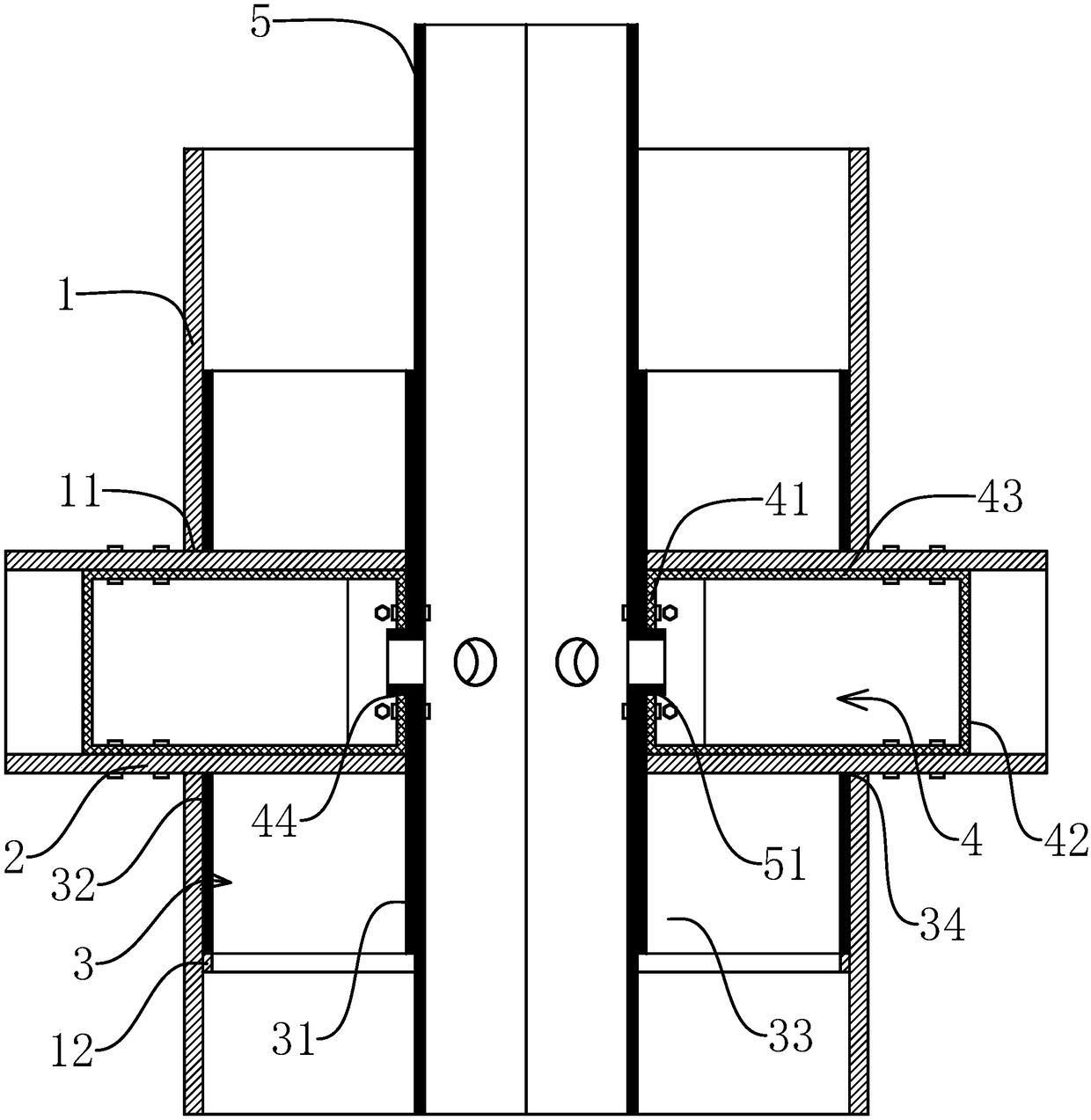

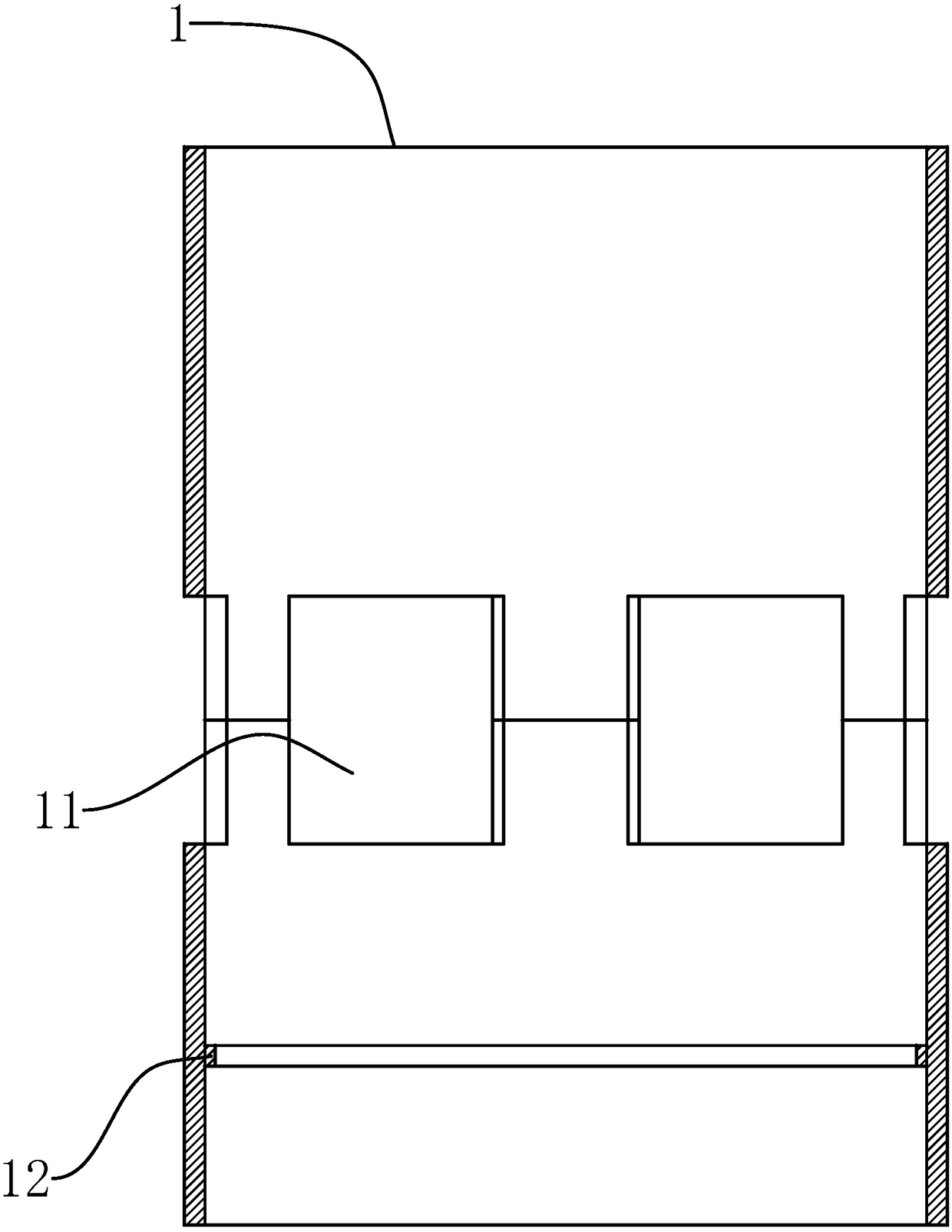

[0040] like Figure 1-3 As shown, a steel structure beam-column node of the present invention includes a vertically arranged circular tube cylinder 1 and a horizontally arranged square tube beam body 2, and also includes several nodes, and the nodes include a tubular central tube 5 with a regular polygonal cross section and A number of tubular post joints 3 with fan-shaped cross-sections. The post joints 3 include an inner post joint 31, an outer post joint 32 and two side post joints 33. The side post joints 33 of two adjacent post joints 3 The outer surfaces are sequentially bonded and connected, and a plurality of inner column connecting plates 31 are enclosed to form a regular polygonal tubular inner sleeve, and severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com