Blade gas-heat deicing system and mounting method thereof

A blade and gas heating technology, applied in the installation/supporting configuration of wind turbines, monitoring of wind turbines, wind power generation, etc., can solve problems such as dissipation and low heating efficiency, achieve firm fixation, improve heating efficiency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

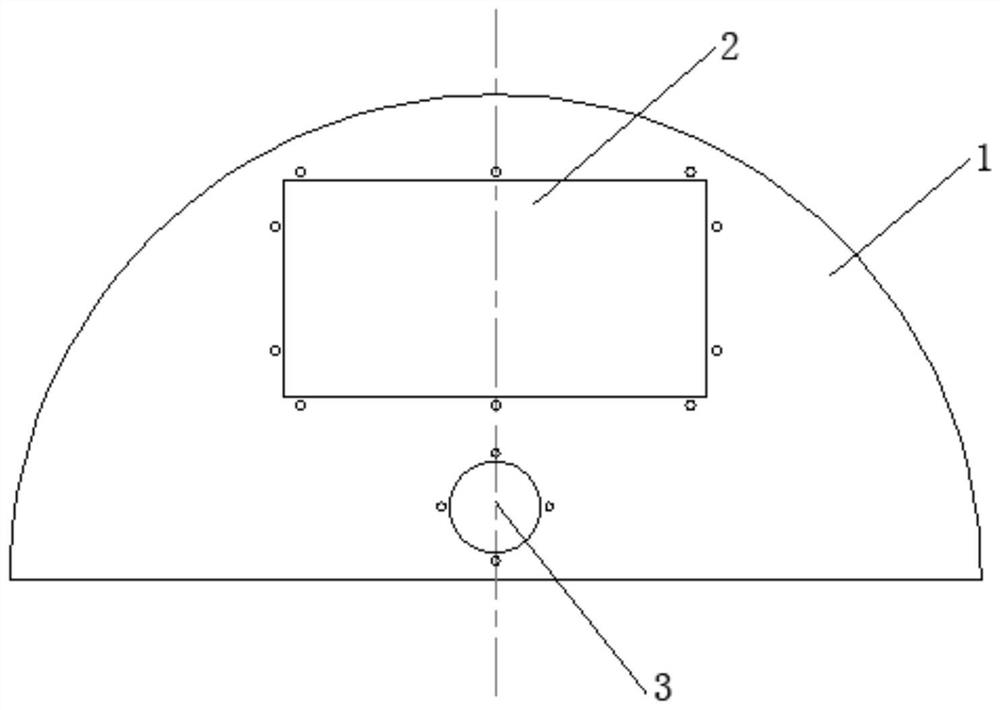

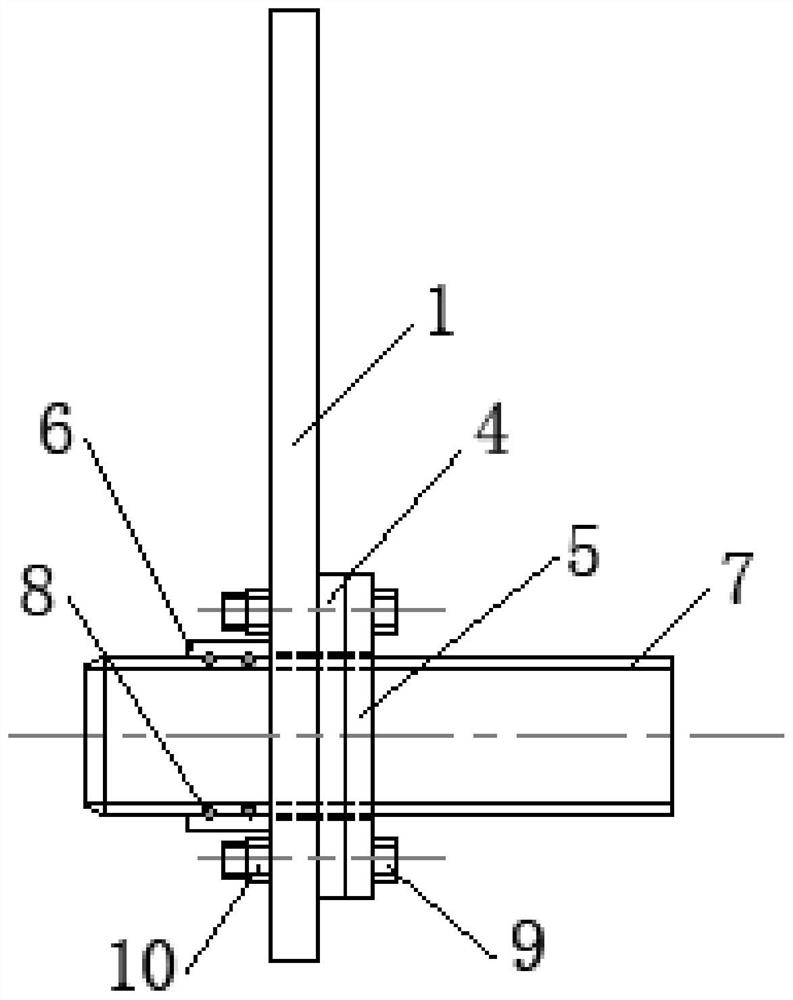

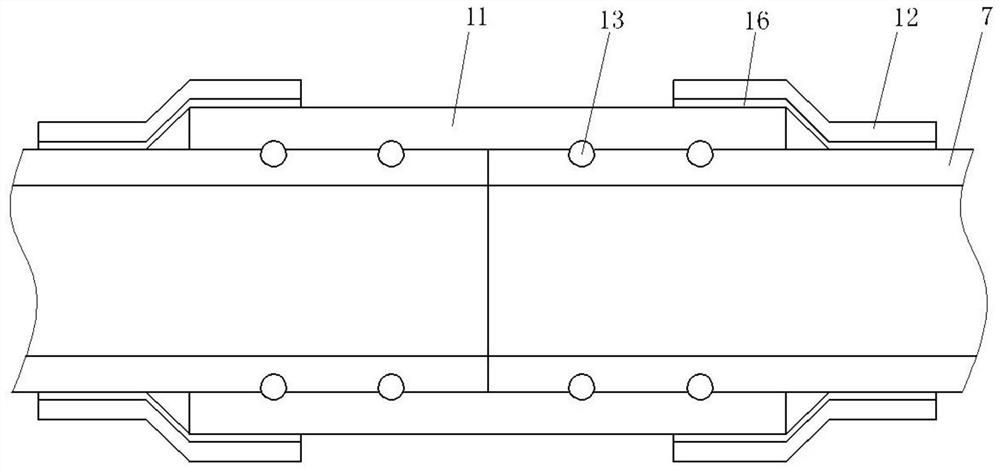

[0052] as attached figure 1 and figure 2 As shown, an aerothermal deicing system for a blade includes a heater, a ventilation duct 7, several hoops, a blower, a baffle 1 and a wiring bracket, and the baffle 1 is bonded between the web and the leading edge of the blade , the baffle plate 1 divides the leading edge cavity between the web and the leading edge of the blade into the first leading edge cavity and the second leading edge cavity, the baffle plate 1 is provided with a mounting hole 3, and several hoops are arranged along the length of the blade The direction is evenly bonded on the web of the blade, the heater is installed in the hoop, the air inlet of the heater is connected with the air outlet of the blower, the air outlet of the heater is connected with the air inlet at one end of the ventilation duct 7, and the ventilation duct 7 Installed in the hoop, the lower part of the blower is provided with a blower bracket, and the blower bracket is bonded on the blade ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com