Electric telescopic snow chains for wheels

A technology of electric telescopic and anti-skid chains, applied in anti-skid devices, vehicle parts, tire parts, etc., can solve the problems of road tire damage, easy loosening and slipping, easy vibration and noise, etc., to prevent loosening or slipping, anti-skid The effect of improving the effect and reducing the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

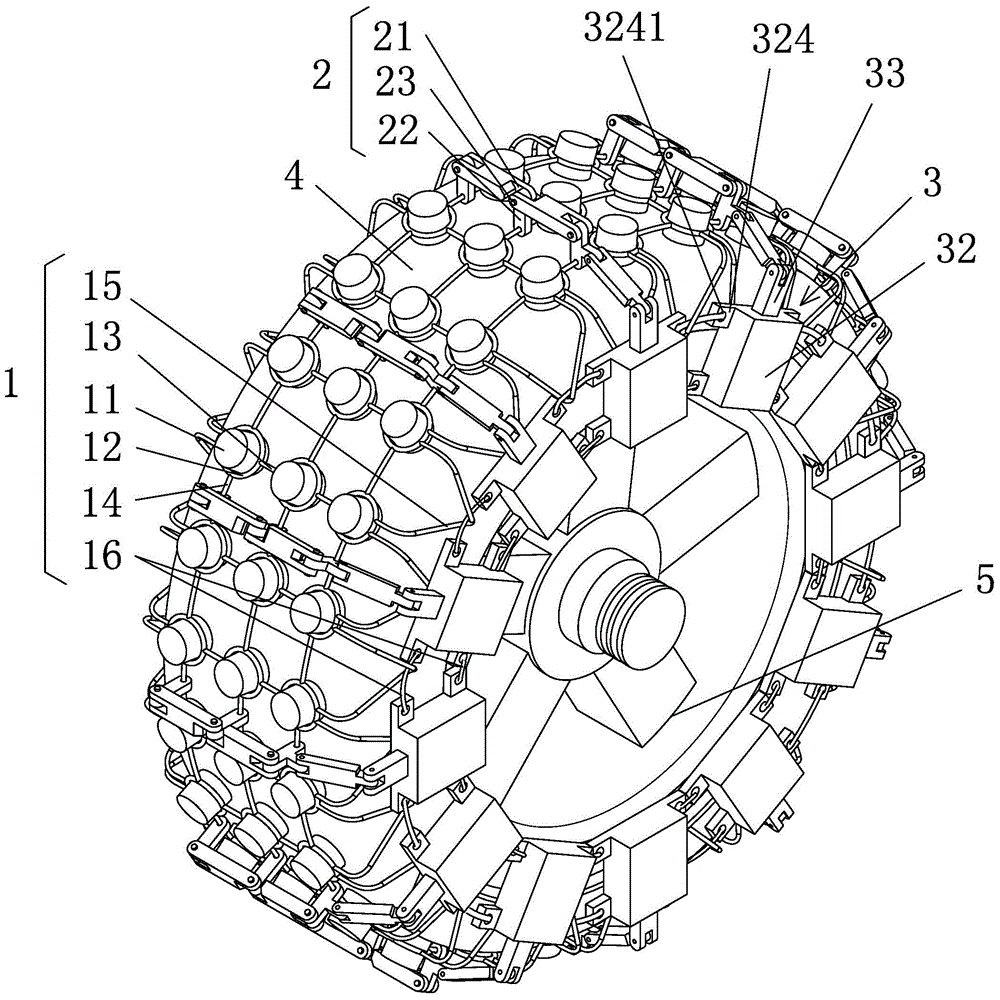

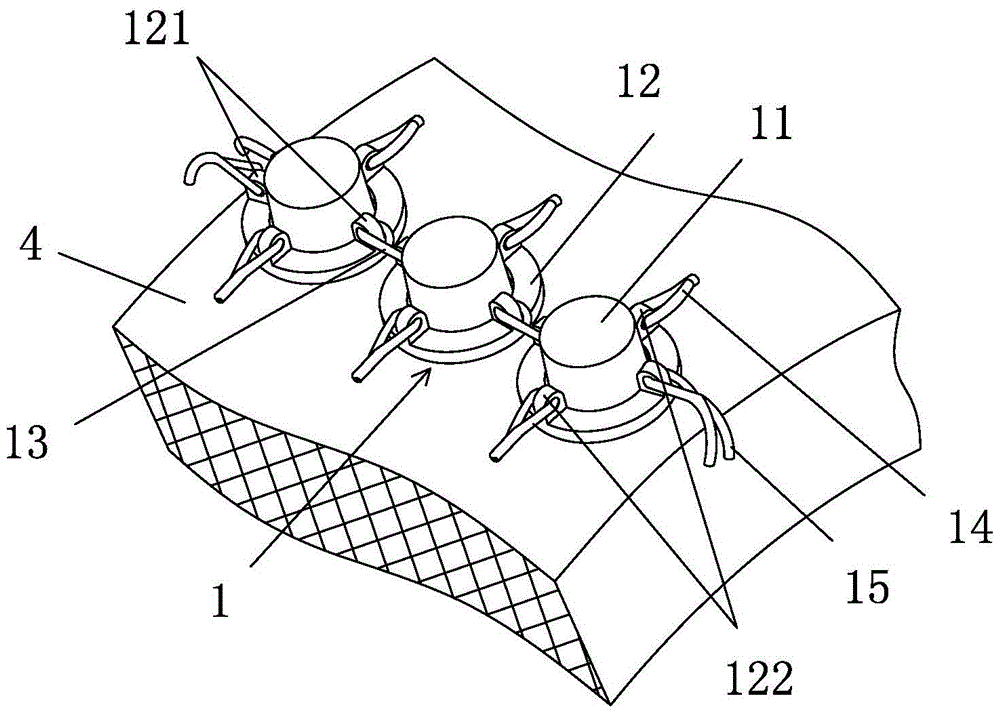

[0022] see figure 1 with figure 2, an electric telescopic anti-skid chain for wheels, the wheel includes a tire 4 and a hub 5 , and the electric telescopic anti-skid chain includes a positioning assembly 1 , a chain body assembly 2 and a lifting assembly 3 . There are multiple sets of positioning assemblies 1, which are arranged at intervals around the circumferential direction of the tire 4 on the outer surface of the tire. Each set of positioning components 1 includes a plurality of positioning piles 11 arranged in a straight line, and the shape of the positioning piles 11 may be a cylinder, an ellipse or a prism. In this embodiment, the positioning pile 11 and the tire 4 are integrally formed and formed into a cylinder, and the number of the positioning pile 11 in each set of positioning components 1 can be set according to the size of the tire 4, and here it is set to three . The positioning pile 11 is covered with a fixed ring 12, and the fixed ring 12 is symmetricall...

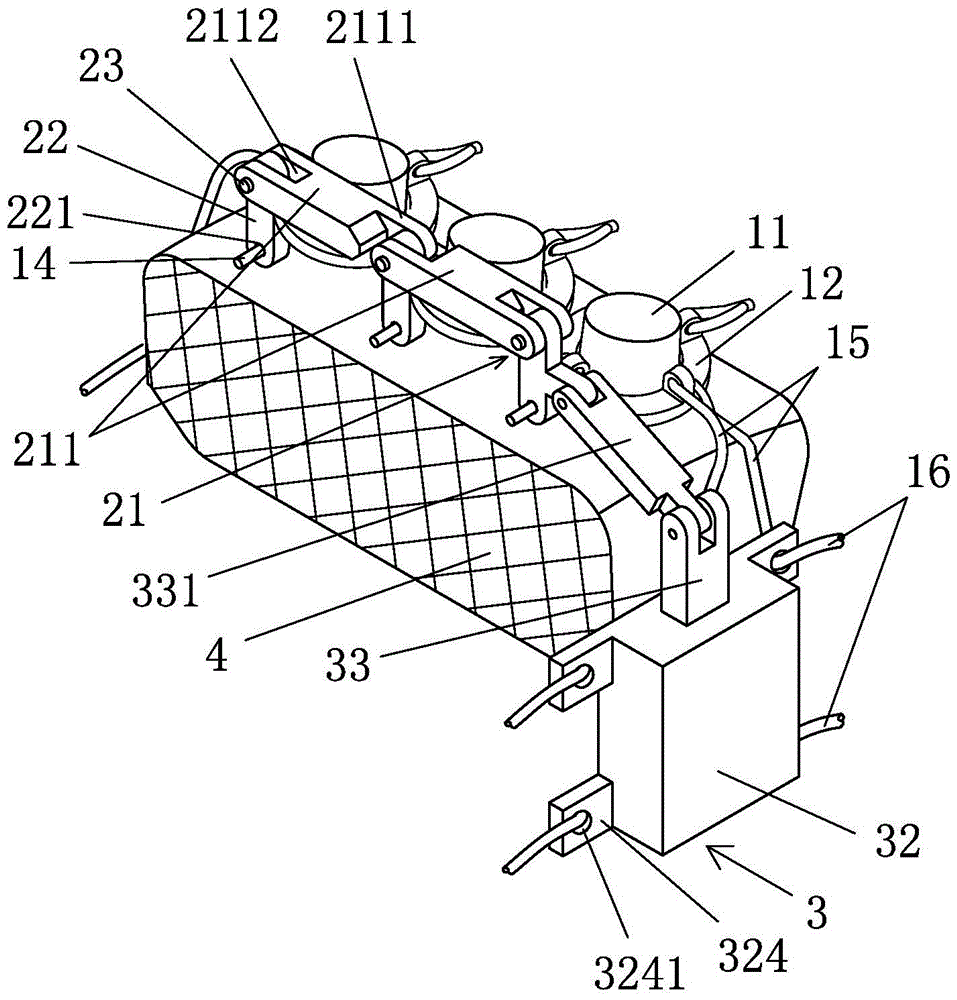

Embodiment 2

[0028] see Figure 4 , in this embodiment, the number of positioning piles 11 and supporting feet 22 in each set of positioning components 1 is four or more, four are shown in the figure. The chain body 21 includes a pair of chain heads 211 and a plurality of chain pieces 212 connected between the pair of chain heads 211 . One end of the chain head 211 in the length direction is extended with a first connecting ear 2111, and the other end forms a supporting foot relief groove 2112; the two ends of the chain piece 212 in the length direction are respectively extended with a second connecting ear 2121 , the second connecting ear 2121 is installed in cooperation with the adjacent first connecting ear 2111 or second connecting ear 2121 . Two support feet 22 in the four or more support feet 22, the upper ends of the height direction are respectively adapted to the two support foot relief grooves 2112 and fixed by pins 23, and the upper ends of the other support feet 22 in the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com