Small-tonnage crane, traveling beam thereof and horizontal wheel device for traveling beam

A technology of horizontal wheels and walking beams, applied in the directions of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the problems that the horizontal wheel group cannot be adjusted or is difficult to adjust, so as to reduce maintenance and repair costs, facilitate installation and assembly, The effect of reducing the form factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

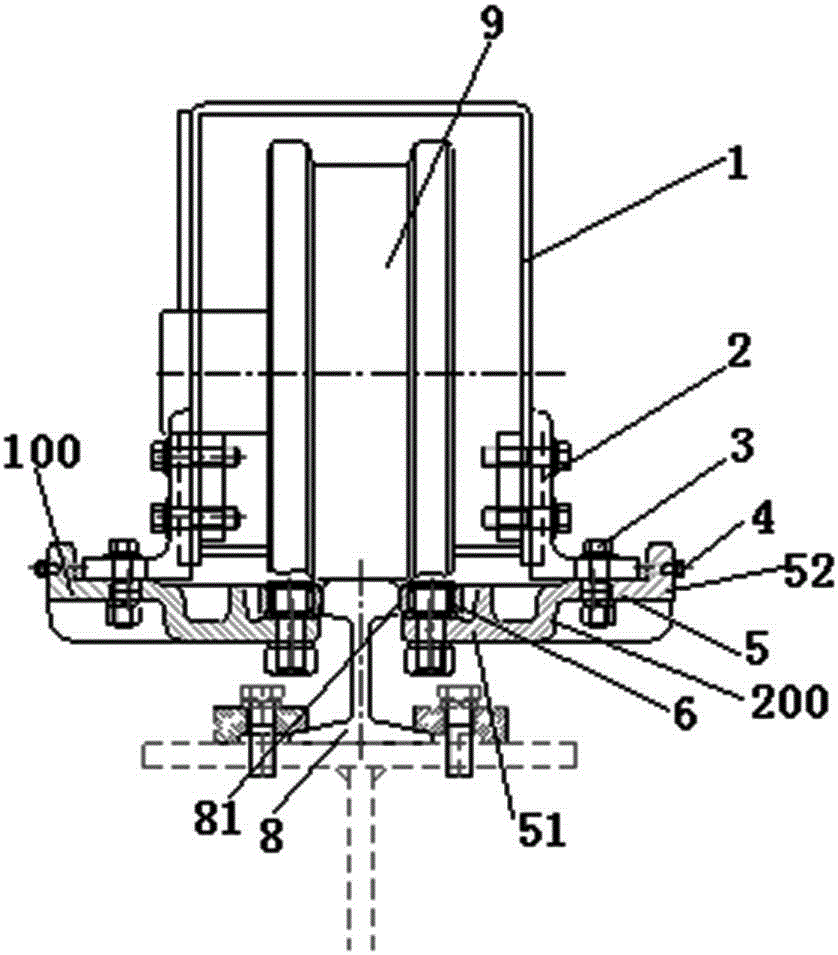

[0020] Such as figure 1 As shown, an embodiment of a crane walking beam, the walking beam in this embodiment includes a beam body 1 extending along the front and rear directions for bearing pressure on the pressure-bearing rail 8, and the front and rear ends of the beam body 1 are respectively rotated and assembled. There is the traveling wheel 9 rollingly matched with the top pressure bearing surface of the pressure bearing track. A left horizontal wheel device 100 and a right horizontal wheel device 200 are installed on the beam body 1 for cooperating to limit the left and right offset of the traveling beam on the bearing rail 8 in the left and right direction.

[0021] The structure of the two horizontal wheel devices is the same, taking the right horizontal wheel device as an example, the right horizontal wheel device includes a horizontal wheel connecting frame 2 fixed on the beam body 1 and fixedly assembled with the horizontal wheel connecting frame 2 to be installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com