An optimization method for the arrangement of measuring points for modal analysis of high-pile wharf

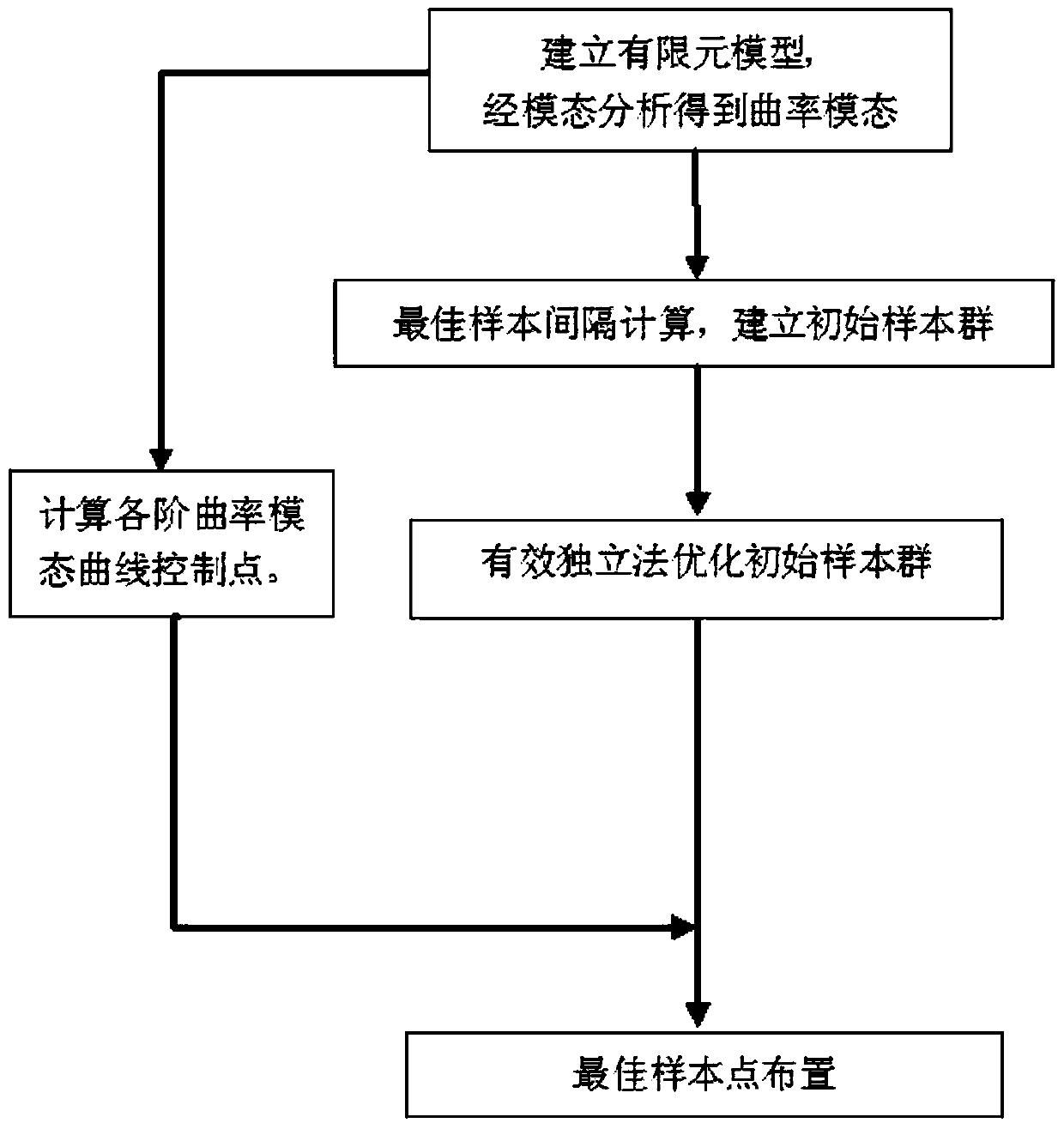

A high-pile wharf, modal analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of redundancy of measurement points, large number of measurement points, and the inability to best express the characteristics of curvature modal curves and other problems to achieve the effect of ensuring linear independence and optimizing the layout method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

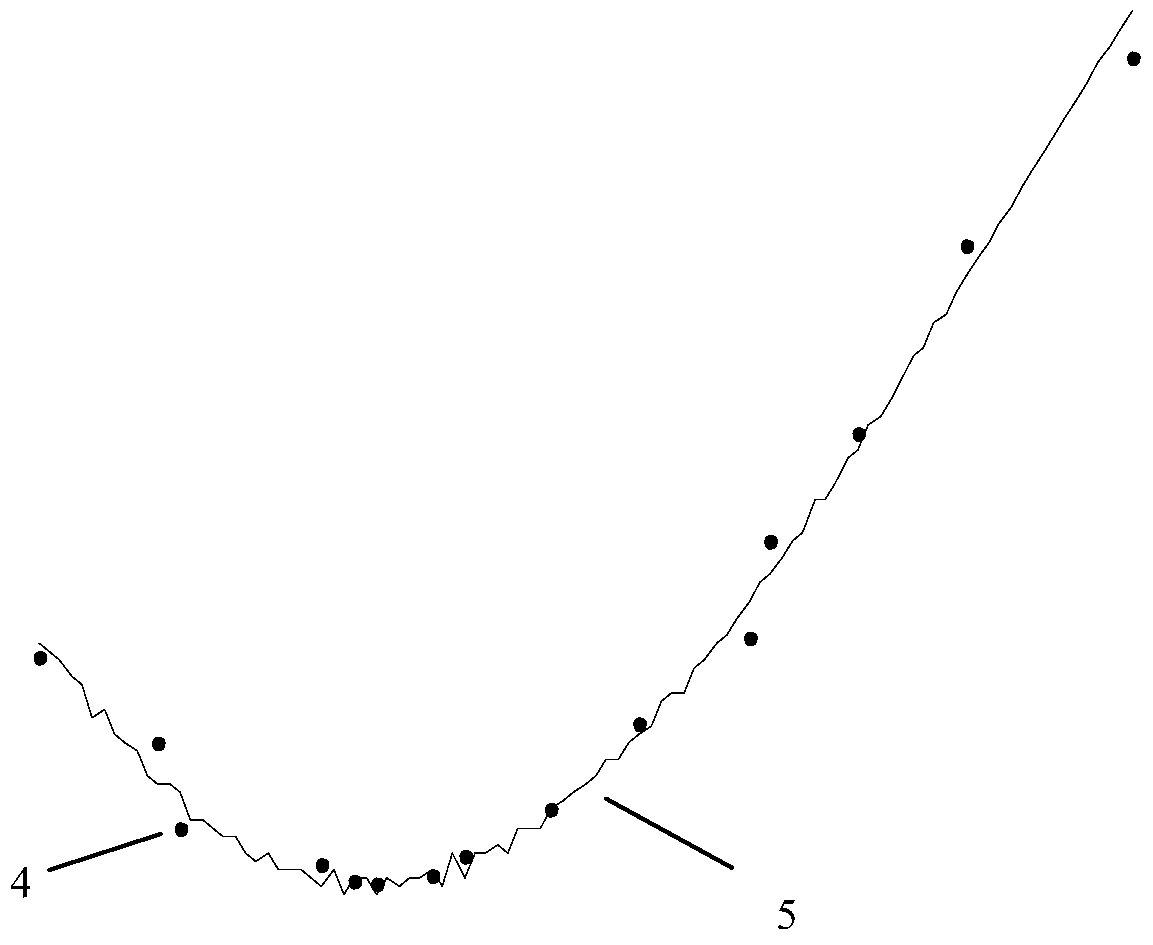

[0030] attached Figure 3-8 The dotted point 4 in represents the measured curvature mode, and the solid line 5 represents the theoretical curvature mode.

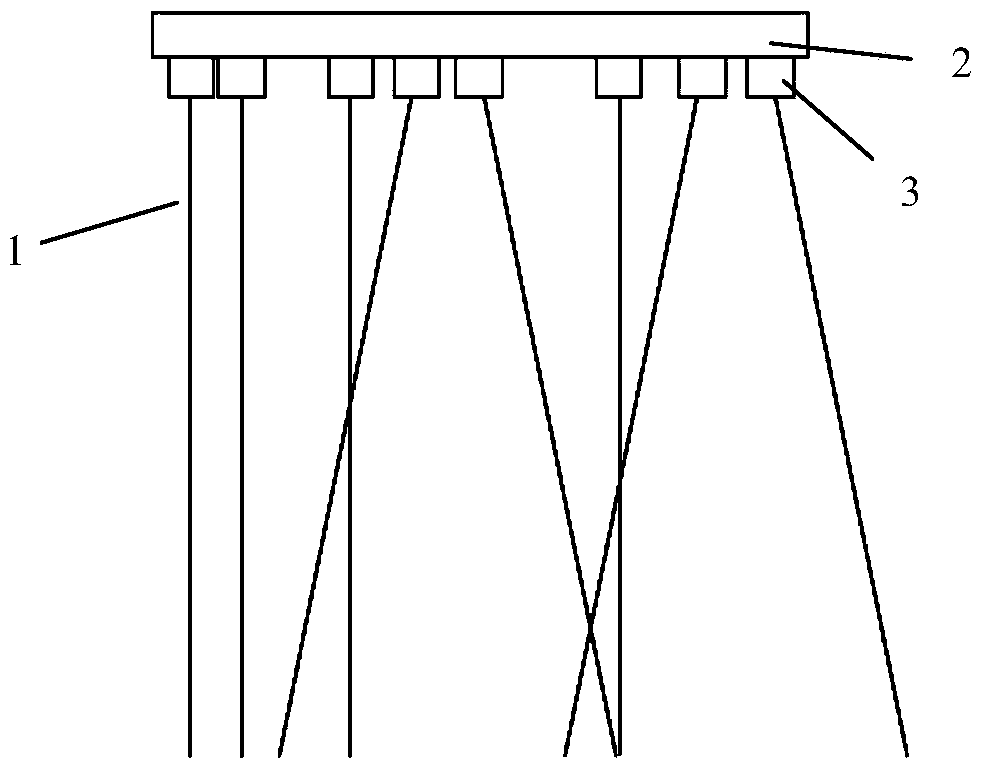

[0031] Take the high pile wharf of a certain port as an example. The high-piled wharf platform is 203m long, 23.4m wide, the average pile length is about 47m, and the concrete material density of the pile foundation is 2550kg / m 3 , the modulus of elasticity is 3.28×10 10 N / m 2 , Poisson's ratio is 0.2, taking a typical five-span high-piled wharf structure composed of six rows of frames as the research object, and optimizing the arrangement of modal measuring points on the No. 1 pile and both sides of the wharf panel.

[0032] figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com