Conveyor device for loading or unloading piece goods which can be singulated

A technology for conveying devices and goods, which is applied in the direction of loading/unloading, conveyors, storage devices, etc., which can solve the problems of restrictive structure and unfavorable conveying speed, and achieve the effect of improving the freedom of positioning and movement, and optimizing the possibility of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

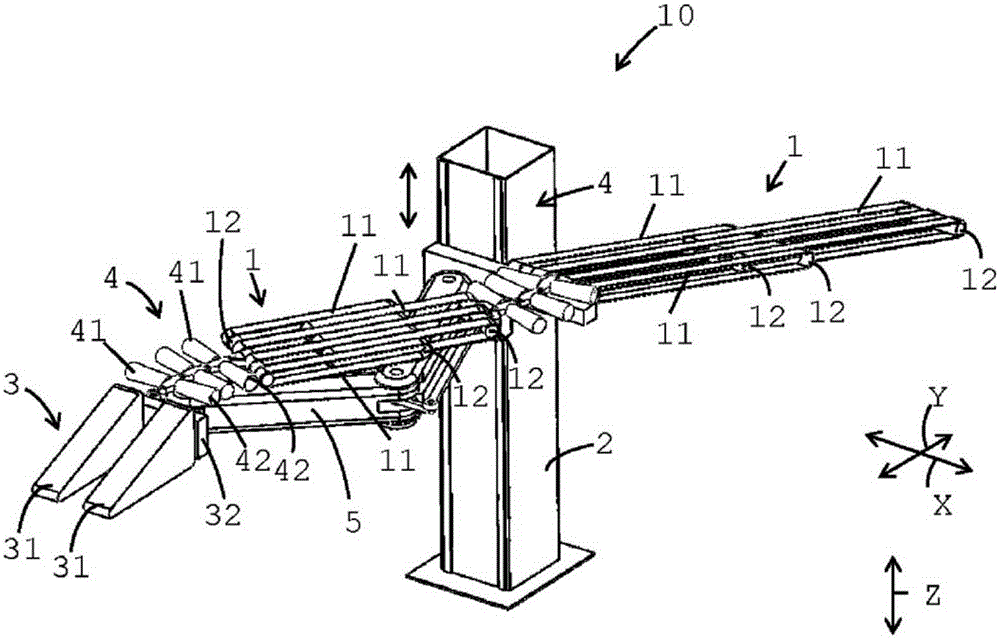

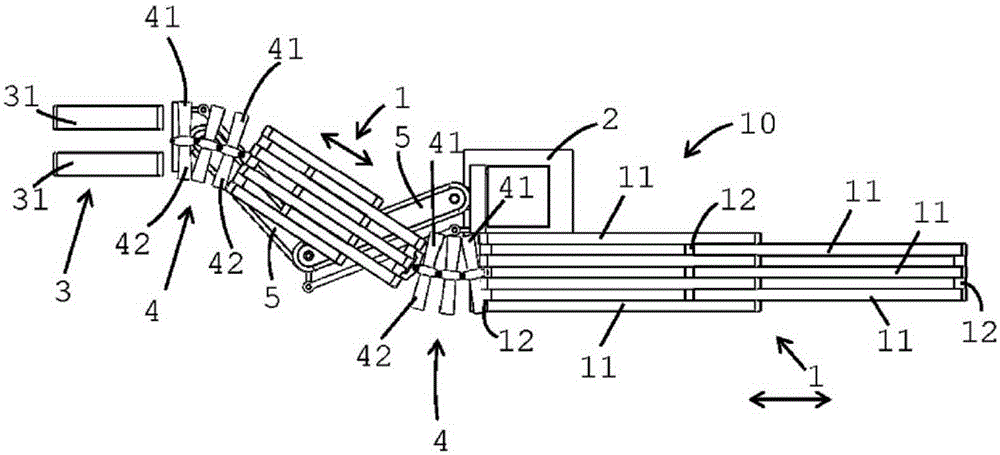

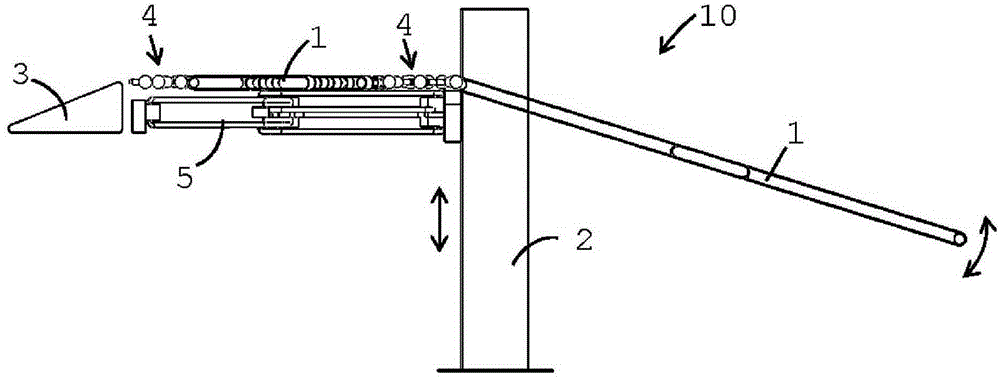

[0033] exist Figures 1 to 10 An example embodiment of a delivery device 10 according to the present invention in various positions and orientations is shown in several views. as in figure 1 and 2 As shown in , the conveyor device 10 basically has three distinct components, namely a conveyor belt device 1 , a bending module 4 and a roll-on module 3 at the front free end. In this exemplary embodiment, the conveyor device 10 is carried by a central support 2 , which is designed here as a fixed lifting column. However, the stand 2 can also be a mobile stand, which is mounted, for example, on a vehicle. The roll-on module 3 here consists of two parallel, side-by-side, inclined belt ramps 31 which are attached at their rear ends via fastening plates 32 . The inclined belt ramps 31 of the roll-on modules 3 are each constructed with a surrounding belt (not shown), so that the received individual goods are drawn onto the roll-on modules 3 and can be transported further.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com