Aseismic connection device for connecting a panel to a beam

A connecting device and connecting technology, applied in the direction of building components, building types, walls, etc., can solve the problem of not being able to guide relative displacement, and achieve the effect of avoiding high shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

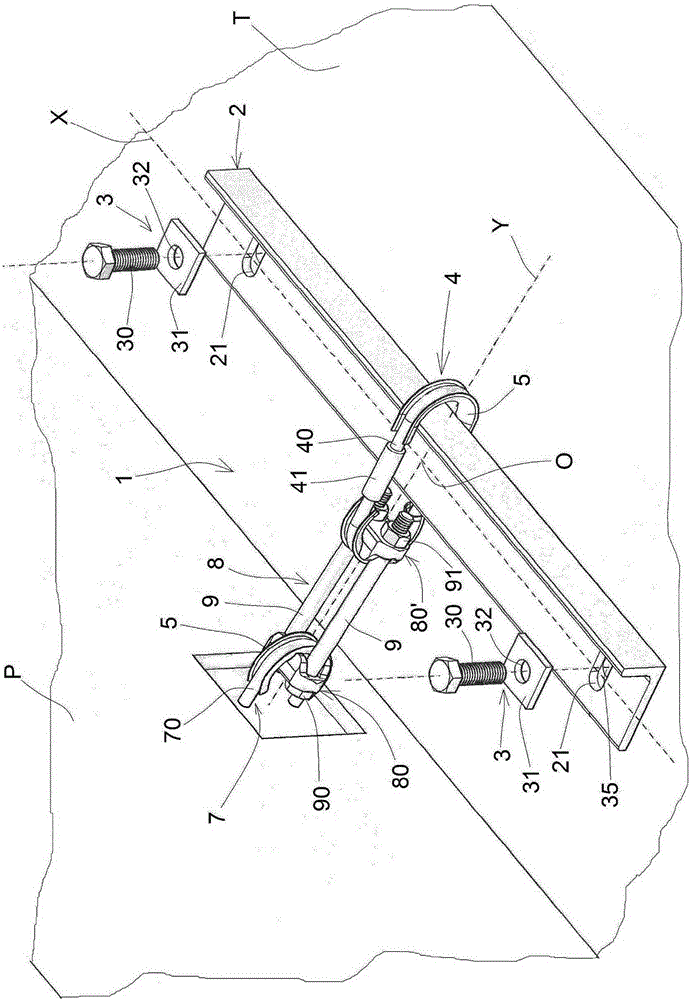

[0027] With reference to the drawings, a connection device according to the present invention is disclosed, which is generally indicated by the reference numeral 1.

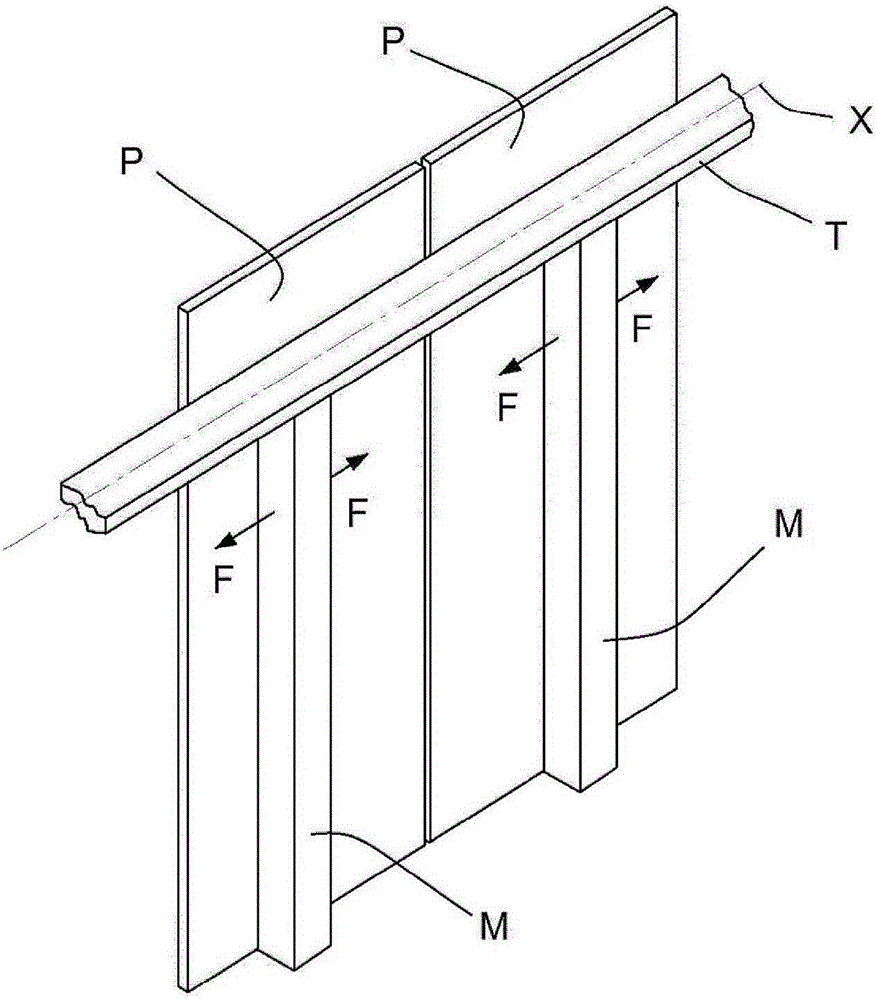

[0028] figure 2 A beam T and a panel P adapted to be connected to the beam T by the connecting device 1 are shown. In the following description, the terms "transverse" and "longitudinal" refer to the transverse and longitudinal directions of the beam T, respectively.

[0029] When connecting the panel P to the beam, the inner surface of the panel abuts against the longitudinal edge of the beam, and the upper surface of the beam is perpendicular to the inner surface of the panel.

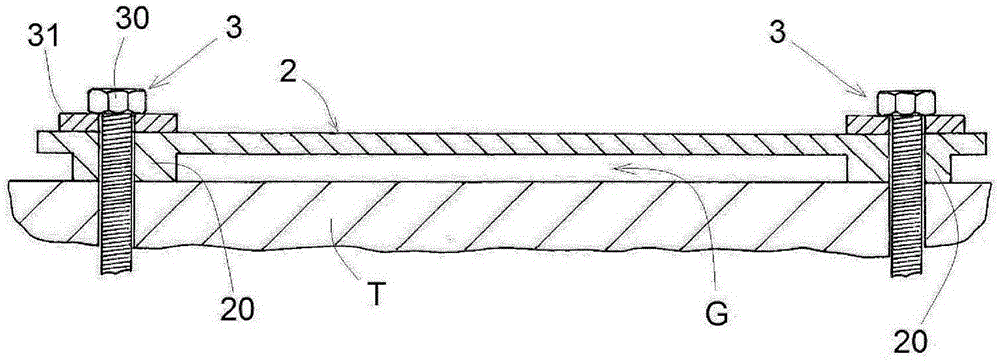

[0030] The connecting device 1 comprises a dispersing element 2 which is shaped as a deformable rod in cross section and has a longitudinal axis X. The dispersion element 2 is fixed to the beam T so that the longitudinal axis X of the dispersion element is parallel to the longitudinal axis of the beam.

[0031] For illustrative purposes, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com