Mixing device

A mixing device and mixing chamber technology, applied in mixers, mixing methods, fluid mixers, etc., can solve problems such as adverse effects of compressibility measurement accuracy, inability to accurately adjust proportions, etc., to avoid high shear force, temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

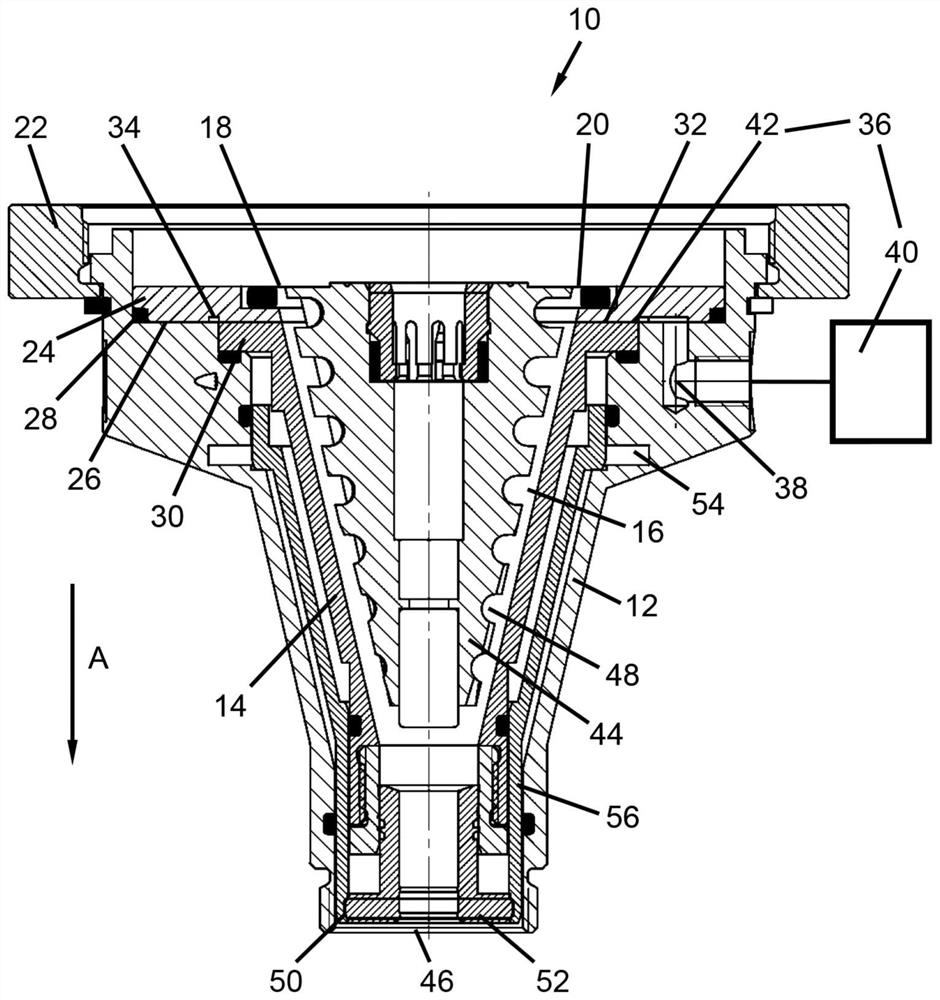

[0030] exist figure 1 , the mixing device according to the invention is indicated generally by the reference numeral 10 . The mixing device 10 comprises a housing 12 in which an element 14 extending in the main flow direction A of the liquid flowing through the mixing device 10 is arranged. Element 14 forms the outer wall of a mixing chamber 16 . A first liquid is introduced into the mixing chamber 16 at a first entry point 18 into the mixing chamber 16 . A second liquid is introduced into the mixing chamber 16 at a second entry point 20 .

[0031] The respective sources or reservoirs of the first liquid and the second liquid are arranged in a superordinate assembly (not shown) which is arranged upstream with respect to the main flow direction A and which the mixing device 10 can be connected to by means of a fastening nut 22 Fastening means 22 are connected to the superordinate assembly.

[0032] Close to the entry points 18 and 20 of the two liquids, a first planar eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com