High-pressure nitrogen gas power ring road system

A high-pressure nitrogen, compressed nitrogen technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of difficult test data analysis, loss of drag reduction effect, structural damage, etc., to ensure the effect of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] figure 1 A schematic structural diagram of a high-pressure nitrogen power loop system according to an embodiment of the present invention is shown. like figure 1 As shown, the high-pressure nitrogen power loop system 100 mainly includes a nitrogen power device 10 and a loop device 20 . The nitrogen power device 10 is used to provide high-pressure nitrogen for the loop device 20 as a power source for controlling the pressure to start, and the oil in the loop device 20 flows in the loop under the driving action of the high-pressure nitrogen.

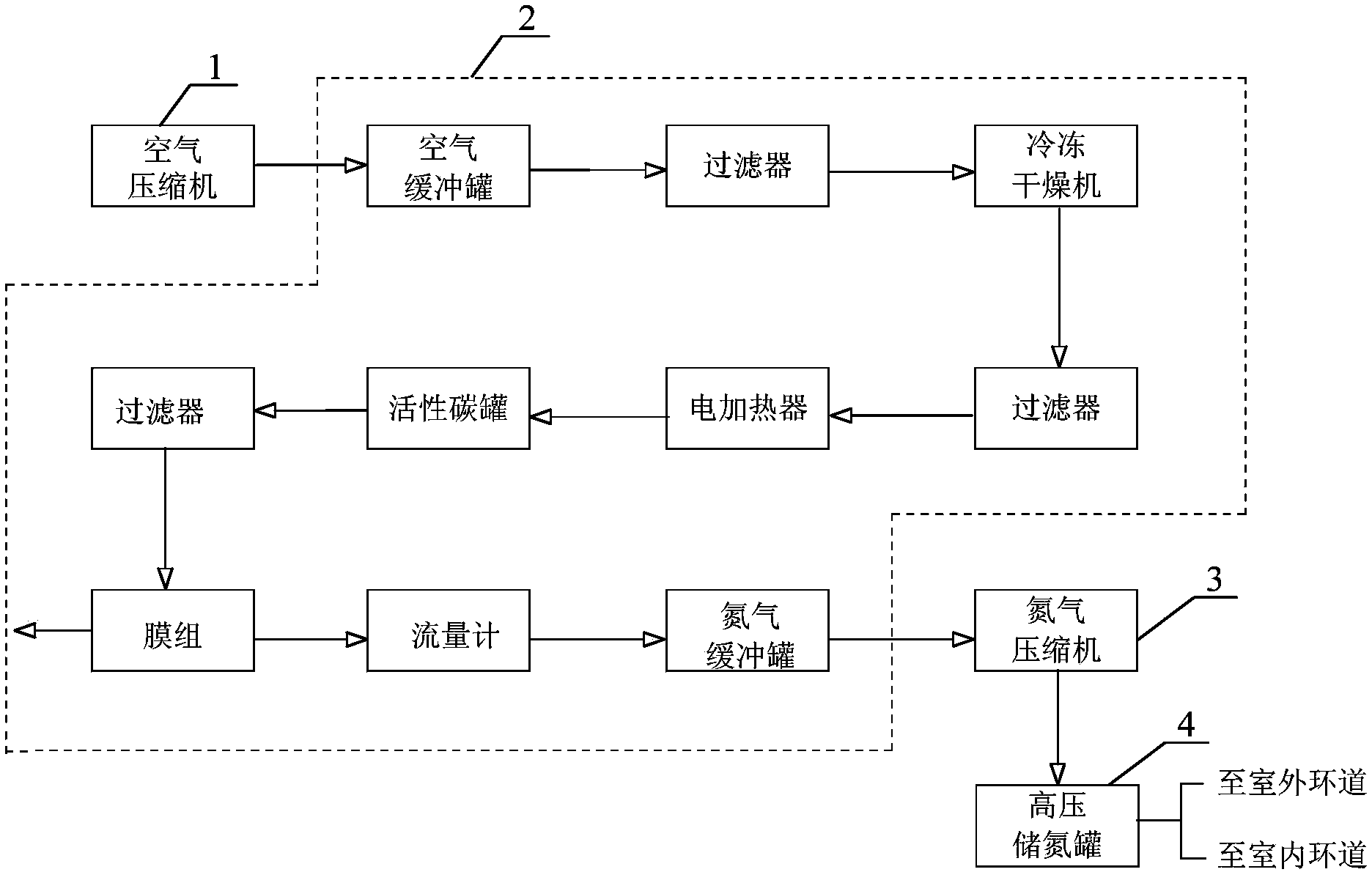

[0046] like figure 2 As shown, in this embodiment, the nitrogen power device 10 mainly includes: an air compressor 1 , a membrane nitrogen generating unit 2 , a nitrogen compressor 3 and a high-pressure nitrogen storage tank 4 .

[0047] Among them, the air compressor 1 is used for compressing air. The membrane nitrogen making unit 2 is connected with the air compressor 1, and is used to separate oxygen and nitrogen from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com