Tensioning rail with resilient press-on region

A technology of tensioning rail and area, applied in belt/chain/gear, transmission, mechanical equipment, etc., can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

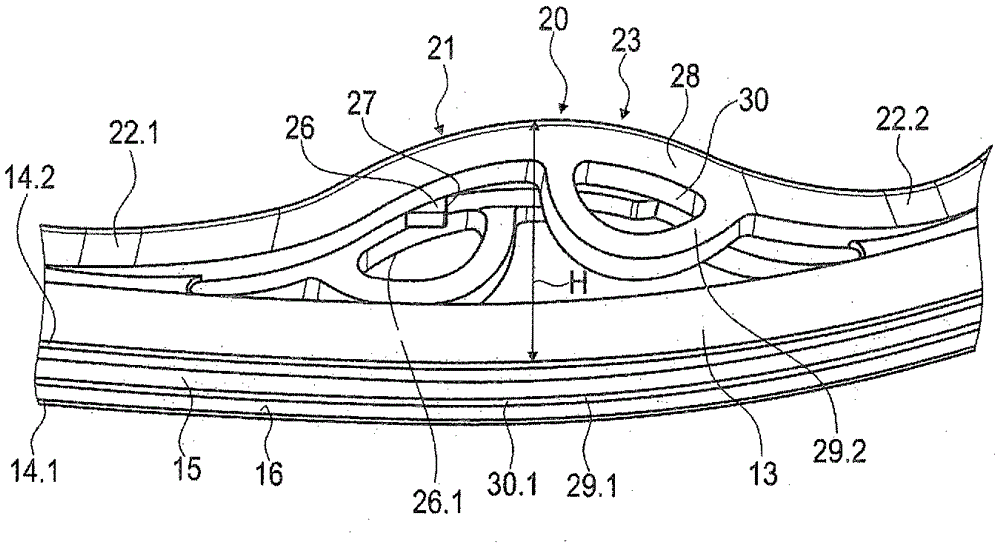

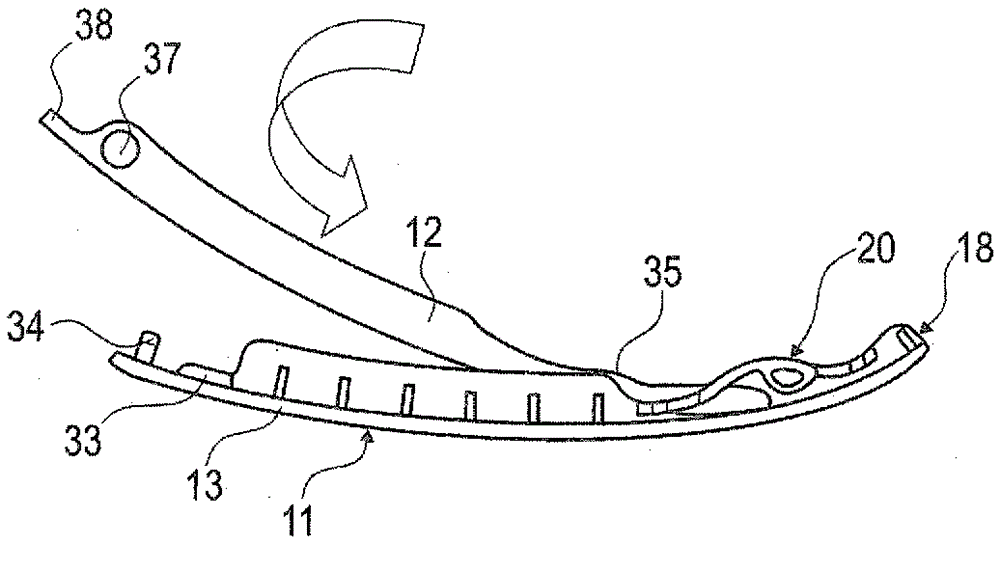

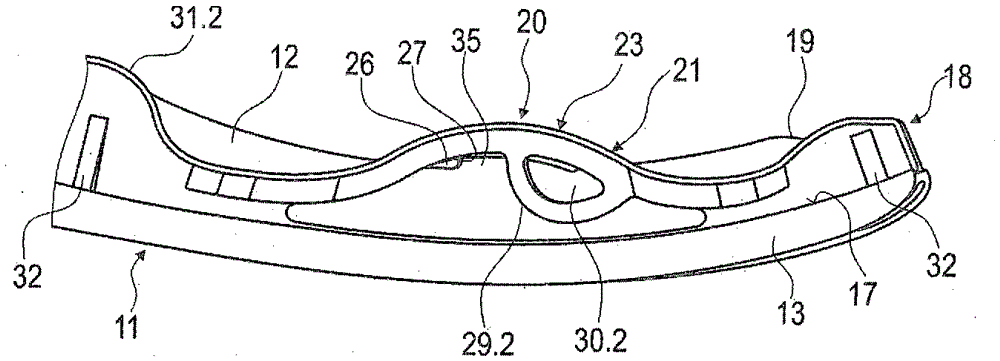

[0032] in figure 1 The timing chain transmission device 1 is schematically shown in FIG. The timing chain transmission device basically includes a crankshaft sprocket 2, two camshaft sprockets 3.1 and 3.2 located above, and placed around the sprockets 2, 3.1, 3.2 The ring-shaped timing chain 4 and the guide rail 5 and the tension rail 6. The tensioning rail 6 is pivotally supported at its pivot point 7 and is pressed against the timing chain 4 by means of a chain tensioner 8 arranged in the part of the engine housing 9 in a manner that is of the chain tensioner 8 The tensioning piston 10 presses against the back side of the tensioning rail 6.

[0033] The guide rail 5 is assigned to the tight side (Zugtrum) of the timing chain drive 1 and is assigned to the loose side (Lostrum) via the tension rail 6. This kind of timing chain transmission device 1 is a highly dynamic device, which on the one hand must solve high rotational speeds and on the other hand must also bear alternat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com