Spindle drive for adjusting elements of motor vehicles

A technology for adjusting components and drives, which is applied to vehicle components, transmissions, wing and fan components, etc., to achieve uniform force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

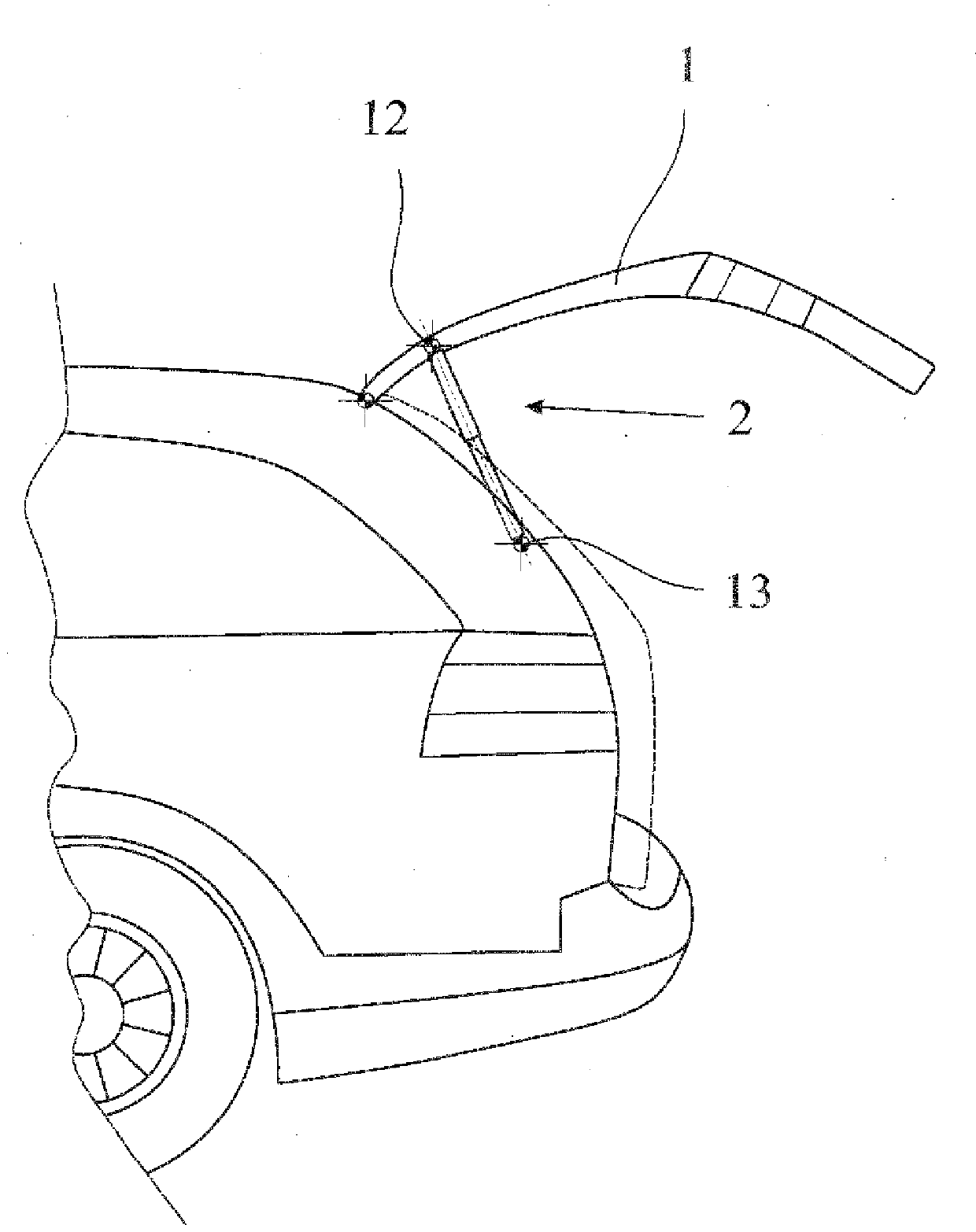

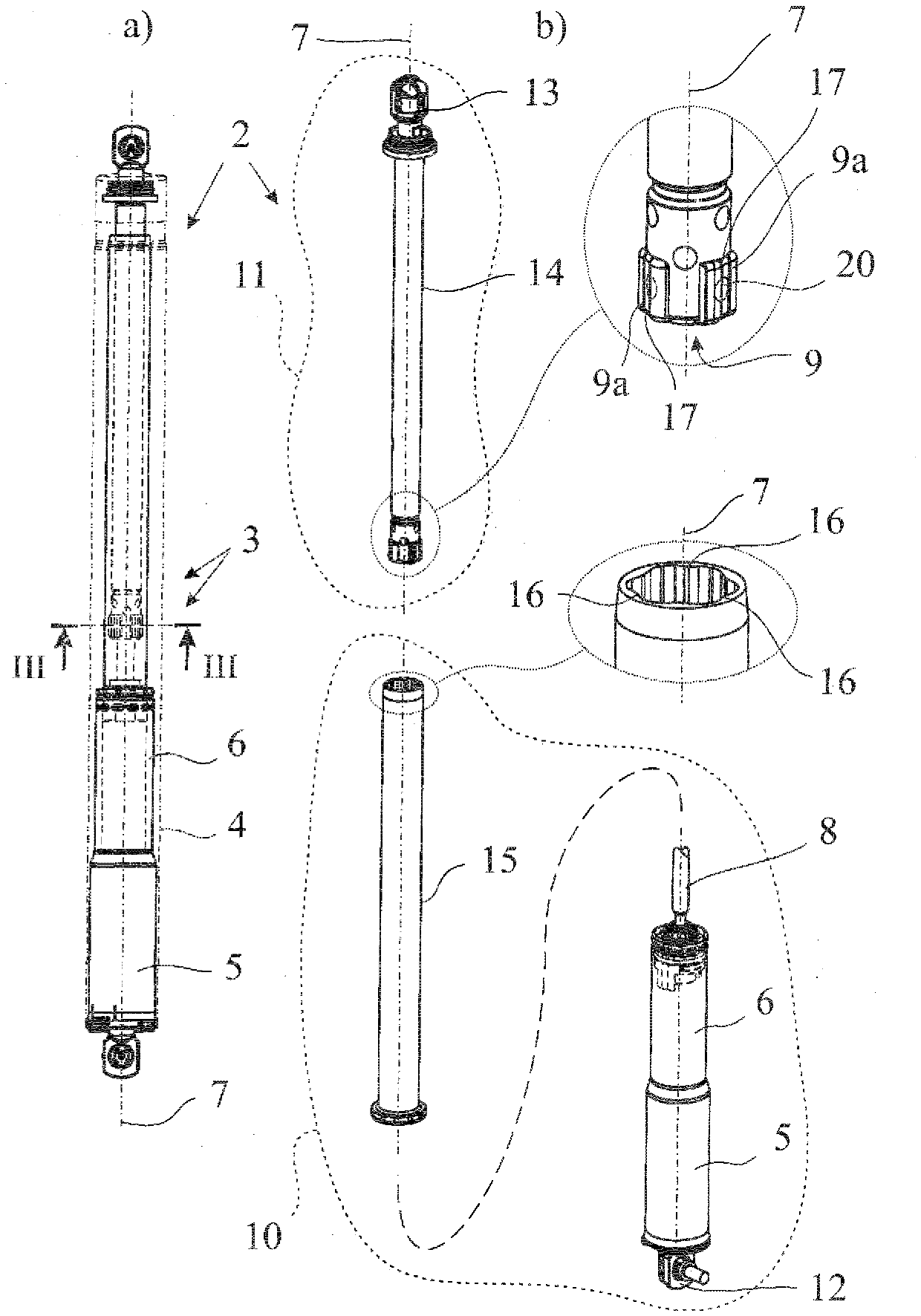

[0026] The spindle drive shown in the figure is used for motorized adjustment of an adjusting element 1 designed as a rear lid of a motor vehicle. As will be explained in more detail below, other fields of application of the proposed spindle drive are conceivable.

[0027] The spindle drive is conventionally equipped with a drive unit 2 and a spindle-spindle nut transmission 3 downstream of the drive unit 2 for generating the linear drive movement. In this case, the drive unit 2 has a here and preferably tubular and in particular one-piece drive unit housing with the drive motor 5 therein as well as an intermediate transmission 6 downstream of the drive motor 5 in terms of drive technology. Depending on the design of the drive motor, the intermediate gear 6 can also be omitted.

[0028] This results in a particularly slim design, in that the drive unit 2 and the spindle-spindle nut drive 3 are arranged one behind the other on the geometric spindle axis 7 .

[0029] In this r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com