A method for improving the adsorption efficiency of mesoporous molecular sieves for heavy metals

A technology for adsorbing heavy metals and mesoporous molecular sieves, applied in chemical instruments and methods, adsorption water/sewage treatment, ion exchange, etc., can solve the problem of low heavy metal adsorption efficiency and achieve the effect of improving heavy metal adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation of embodiment 1 molecular sieve

[0017] In this embodiment, the template agent is cetyltrimethylammonium bromide as an example, but the template agent is not limited to this example.

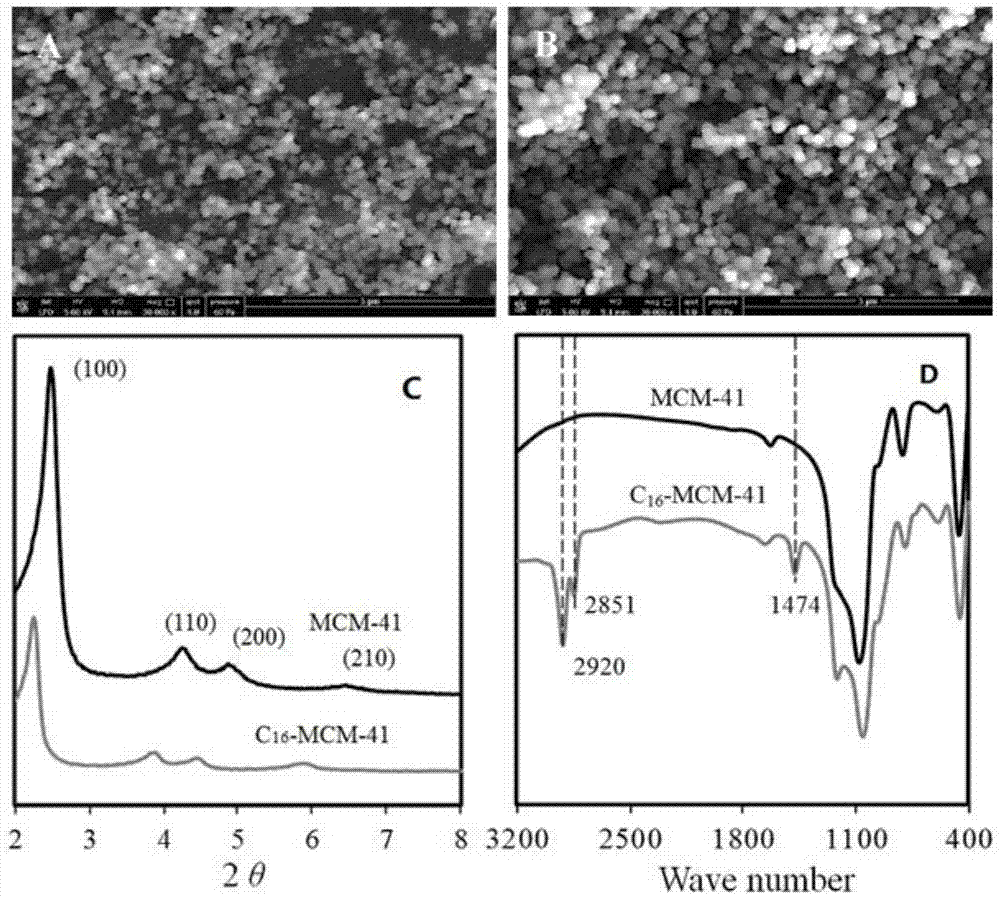

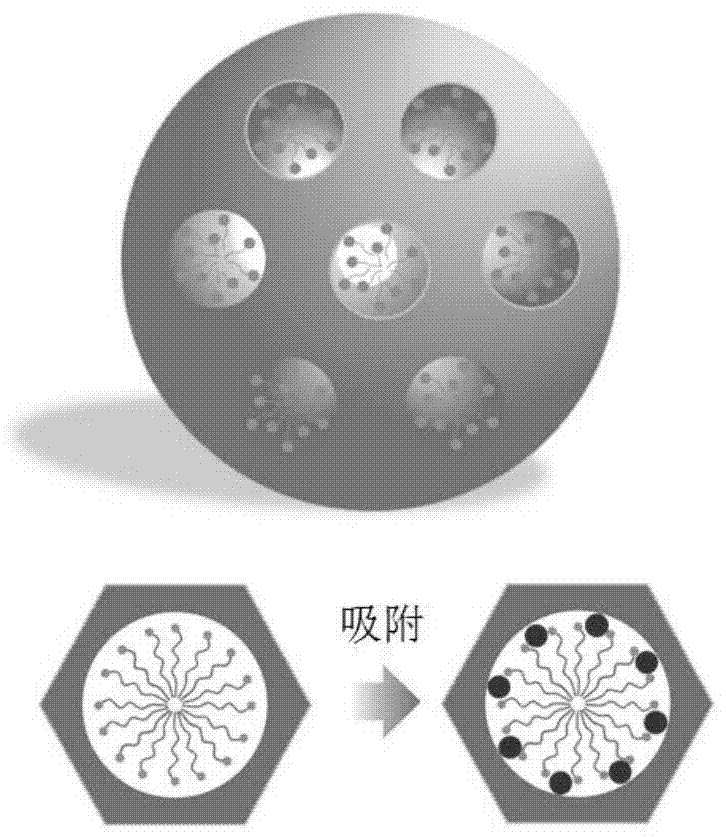

[0018] Add 6g of quaternary ammonium salt surfactant cetyltrimethylammonium bromide to 700mL of water, stir well to dissolve, then add 250mL of ethanol and 80mL of ammonia water in turn, after fully mixing, add 20% orthosilicic acid under stirring Carry out dehydration condensation reaction of ethyl ester for 20 minutes, after aging for 24 hours, separate and wash the white sediment obtained, dry and grind to obtain a silicon-based mesoporous molecular sieve that retains the template agent, and take some samples and calcinate at 540°C for 6 hours to obtain A template-free silica-based mesoporous molecular sieve. For material characterization see figure 1 , the schematic diagram of the material structure is shown in figure 2 . Such as figure 1 As shown in A and 1B, t...

Embodiment 2

[0019] Embodiment 2 adsorption experiment

[0020] In this embodiment, the template-containing silicon-based mesoporous molecular sieve is taken as an example of a molecular sieve prepared by cetyltrimethylammonium bromide, and the heavy metal is Cu 2+ as an example, but the types of templates and heavy metals are not limited to this example.

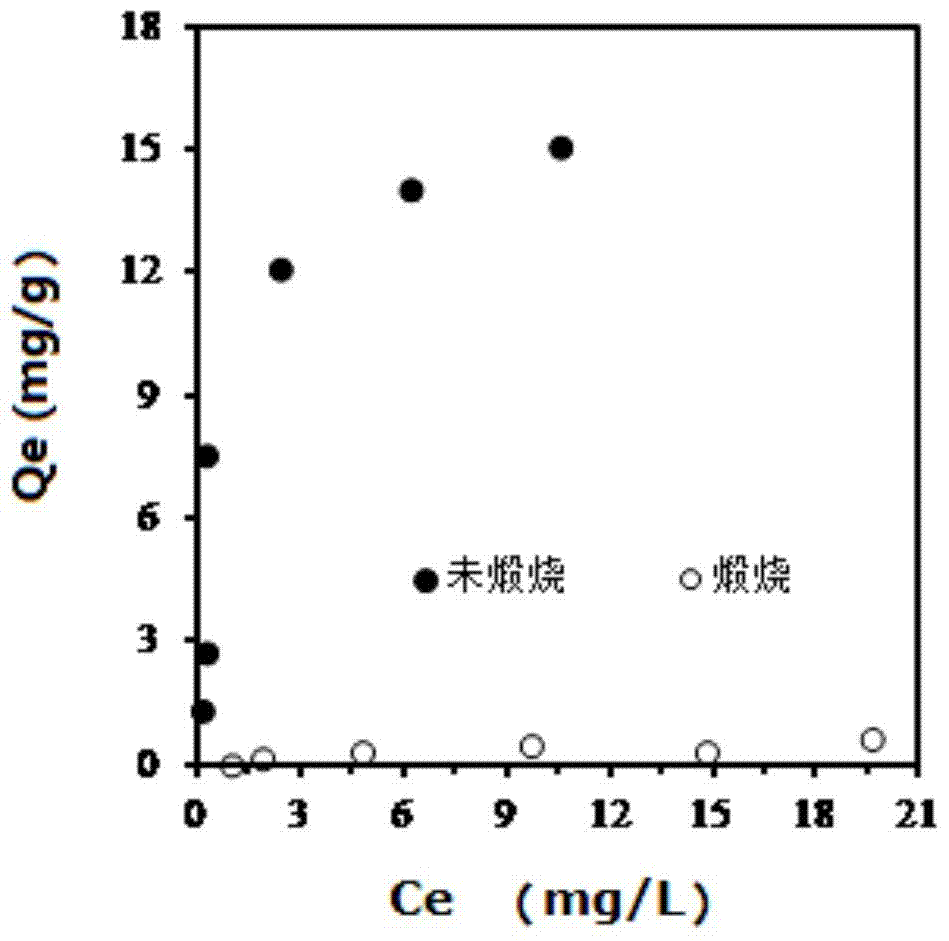

[0021] The effect of retaining template agent on the adsorption of heavy metals by silica-based mesoporous molecular sieves was verified by adsorption experiments. Weigh 0.02 g of the above two molecular sieves and place them in a 50 mL glass centrifuge tube, add 30 mL of distilled water and a certain volume of heavy metal ions to represent Cu 2+ , after finally adjusting the volume of the system to 32mL and adjusting the pH to be neutral, shake at room temperature for 2 hours to reach adsorption equilibrium. Sampling for determination of Cu 2+ residual amount, to evaluate the adsorption performance of the material, so as to verify t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap