Gold nanocluster-gold nanoparticle-titanium dioxide composite photocatalyst and its application

A gold nanocluster and gold nanoparticle technology, which is applied in the gold nanocluster-gold nanoparticle-titanium dioxide composite photocatalyst and application fields, can solve the problems of limiting the practical application of titanium dioxide and the like, and achieves the advantages of sustainable development and high photocatalysis. Activity, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of gold nanocluster-gold nanoparticle-titanium dioxide composite photocatalyst, its preparation method comprises the following steps:

[0026] 1) Dissolve chloroauric acid in water, add reduced glutathione equal to the weight of chloroauric acid, stir until colorless, then reflux at 70°C for 24 h, add acetonitrile for purification, centrifuge, wash and dry, obtaining solid gold nanoclusters, and redispersing the obtained solid gold nanoclusters into water to obtain a gold nanocluster solution;

[0027] 2) According to the weight ratio of titanium dioxide nanoparticles and solid gold nanoclusters of 100:1~100:5, mix and stir the solution of titanium dioxide nanoparticles and gold nanoclusters under weakly acidic conditions with a pH value of 4 for 4 h, centrifuge , washing, and drying to obtain a gold nanocluster-titanium dioxide composite material;

[0028] 3) Add 8 mL of lactic acid as a sacrificial agent to the composite material obtained in step 2) in a vacuu...

Embodiment 1

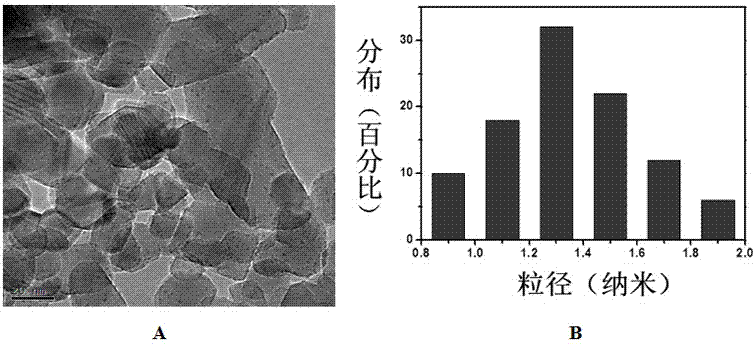

[0041]Dissolve 0.24 g of chloroauric acid in 300 mL of water, add 0.276 g of reduced glutathione and stir until colorless, then reflux at 70 °C for 24 h, add 900 mL of acetonitrile after cooling for purification, centrifuge, wash and dry , the resulting solid is redispersed in water to obtain a gold nanocluster solution; according to the weight ratio of titanium dioxide nanoparticles to solid gold nanoclusters is 100:3, the titanium dioxide nanoparticles are immersed in the gold nanocluster solution, and the solution pH The value was adjusted to 4, stirred for 4 hours, centrifuged, washed, dried, and ground to obtain a gold nanocluster-titanium dioxide composite material. The obtained gold nanocluster-titanium dioxide composite material was irradiated for 3 hours under the conditions of simulating sunlight, vacuum atmosphere, and adding lactic acid as a sacrificial agent. Particles to obtain a gold nanocluster-gold nanoparticle-titanium dioxide composite photocatalyst. The av...

Embodiment 2

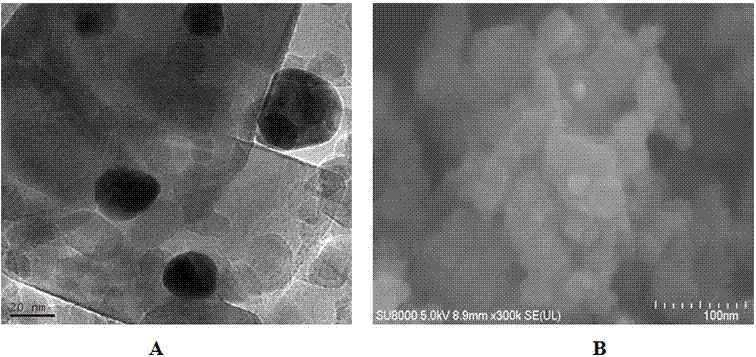

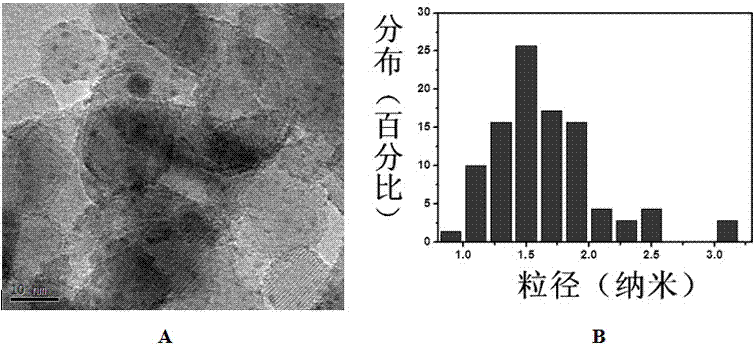

[0043] Dissolve 0.24 g of chloroauric acid in 300 mL of water, add 0.276 g of reduced glutathione and stir until colorless, then reflux at 70 °C for 24 h, add 900 mL of acetonitrile after cooling for purification, centrifuge, wash and dry , the resulting solid is redispersed into water to obtain a gold nanocluster solution; according to the weight ratio of titanium dioxide nanoparticles to solid gold nanoclusters is 100:1, the titanium dioxide nanoparticles are immersed in the gold nanocluster solution, and the solution pH The value was adjusted to 4, stirred for 4 hours, centrifuged, washed, dried, and ground to obtain a gold nanocluster-titanium dioxide composite material. The obtained gold nanocluster-titanium dioxide composite material was irradiated for 60 h under the conditions of simulating sunlight, vacuum atmosphere, and adding lactic acid as a sacrificial agent. Nanoparticles to obtain gold nanoclusters-gold nanoparticles-titanium dioxide composite photocatalyst. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com