Treatment process for degrading printing and dyeing wastewater through bismuth-based composite photocatalyst

A printing and dyeing wastewater and treatment process technology, which is applied in textile industry wastewater treatment, special compound water treatment, light water/sewage treatment, etc., can solve the problems of limited solid powder catalyst application, short lifetime of photogenerated electron-hole pairs, and low photoconversion efficiency and other issues, to achieve the effects of being beneficial to the sustainable development of the environment and energy, promoting light absorption, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

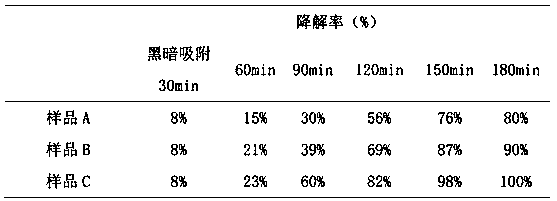

Image

Examples

Embodiment 1

[0027] One, the preparation of graphene oxide:

[0028] In the mixed solution of 350mg graphite powder and 2.4g sodium nitrate, add 21mL of 98wt% concentrated sulfuric acid, stir at a temperature of <5°C, let it react in a beaker for 1.8h; grind potassium permanganate into powder, then Within 0.5h, add 2.0g of powder to the beaker, and react at <5°C for 1.8h; put the beaker in a constant temperature box to raise the temperature to 48°C, and then keep the temperature for 2.2h. After the constant temperature is over, add 45mL of deionized water to the beaker , and then raise the temperature to 85°C, keep the temperature for 15min; then cool the solution in the beaker to room temperature, add 80mL deionized water to dilute, the solution turns bright yellow, then add 13mL 35wt% hydrogen peroxide solution; then carry out Filter, wash the filter residue with 400mL of 5wt% hydrochloric acid, dry it with an air pump and repeat the washing 3 times, then wash it with deionized water 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com