Preparation method and application of titanium dioxide photocatalyst

A photocatalyst and titanium dioxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of difficult industrialization and commercialization, easy poisoning of precious metals, loss of activity, etc., and achieve a wide range of applications , good stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment relates to the preparation of a co-catalyst thiomolybdic acid nanocluster solution, which specifically includes the following steps:

[0039] Dissolve 1.0 g of ammonium molybdate in 50 mL of deionized water, add 15 mL of ammonium polysulfide solution, condense and reflux for 3 d at 70 °C, add toluene after cooling, heat and stir at 60 °C for 2 hours, and separate after cooling to obtain an aqueous layer, Toluene was added to it again, heated and stirred at 60°C for 2 h, cooled and separated to obtain an aqueous layer, and CS was added to it 2 , heated and stirred at 30°C for 2 hours, cooled and centrifuged to separate the water layer, after removing the organic layer, the red precipitate at the bottom was dissolved in water and stored together with the upper water layer to obtain a thiomolybdic acid nanocluster solution.

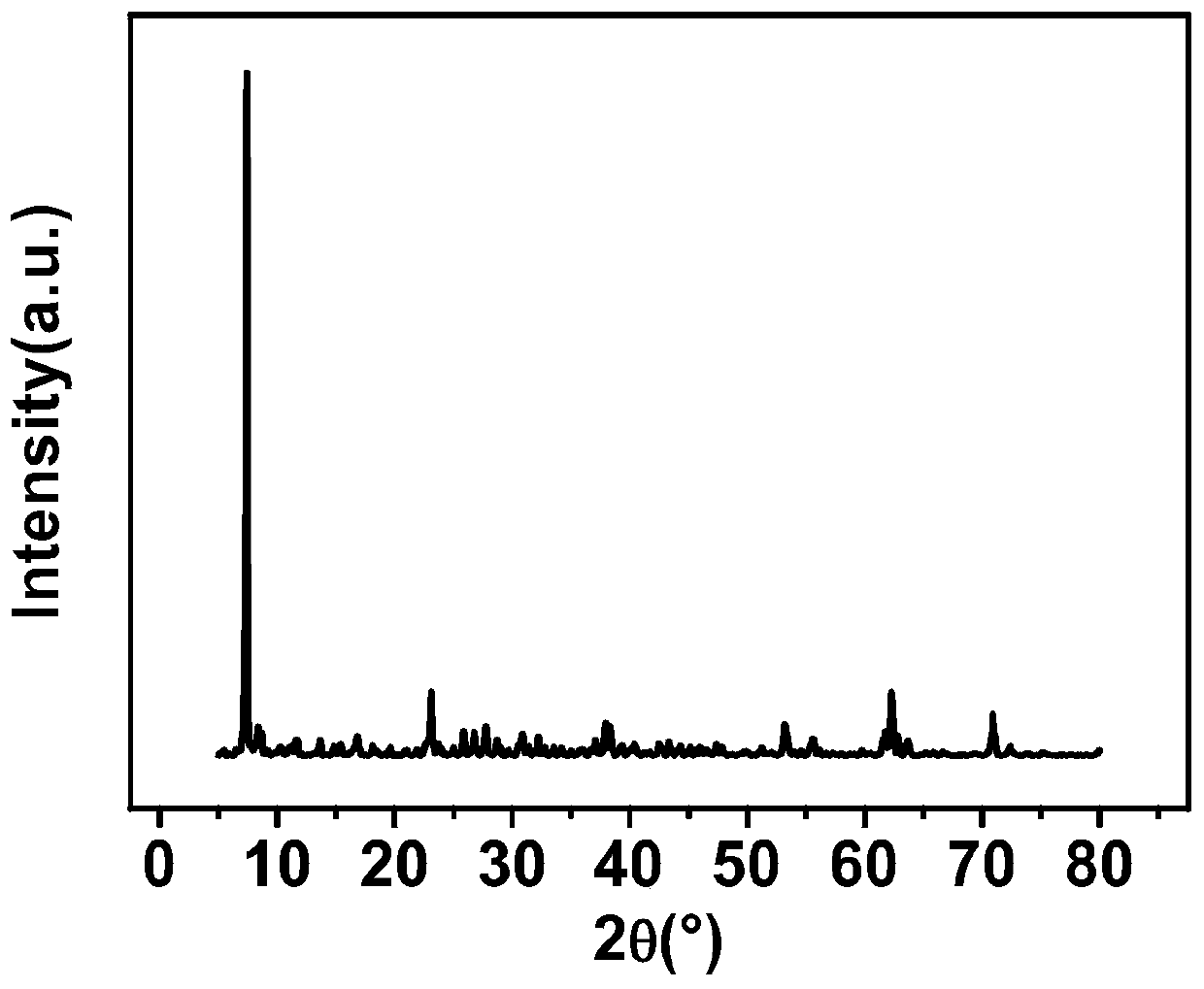

[0040] The XRD pattern analysis of the cocatalyst thiomolybdic acid nanocluster prepared in this example is as follows: figure ...

Embodiment 2

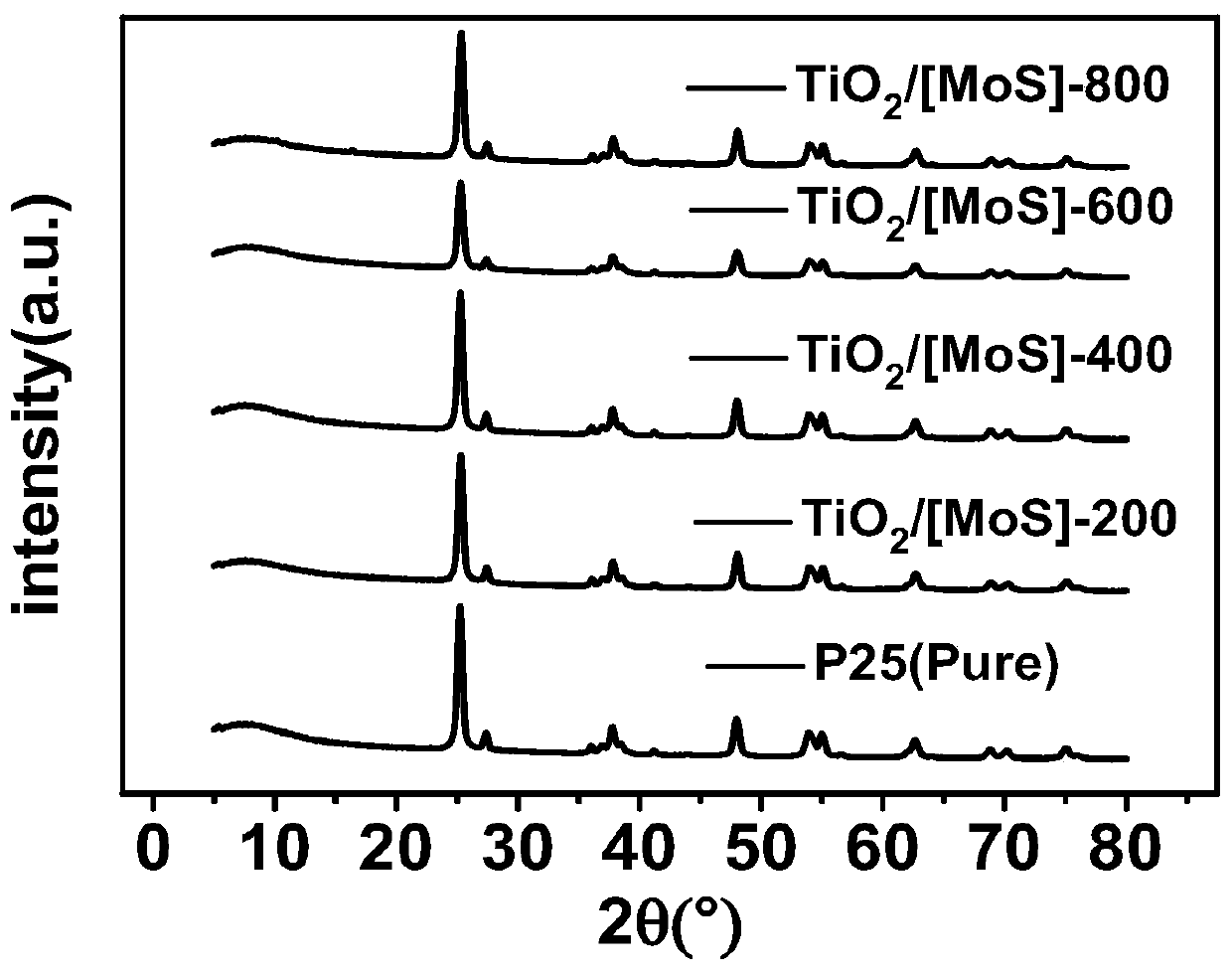

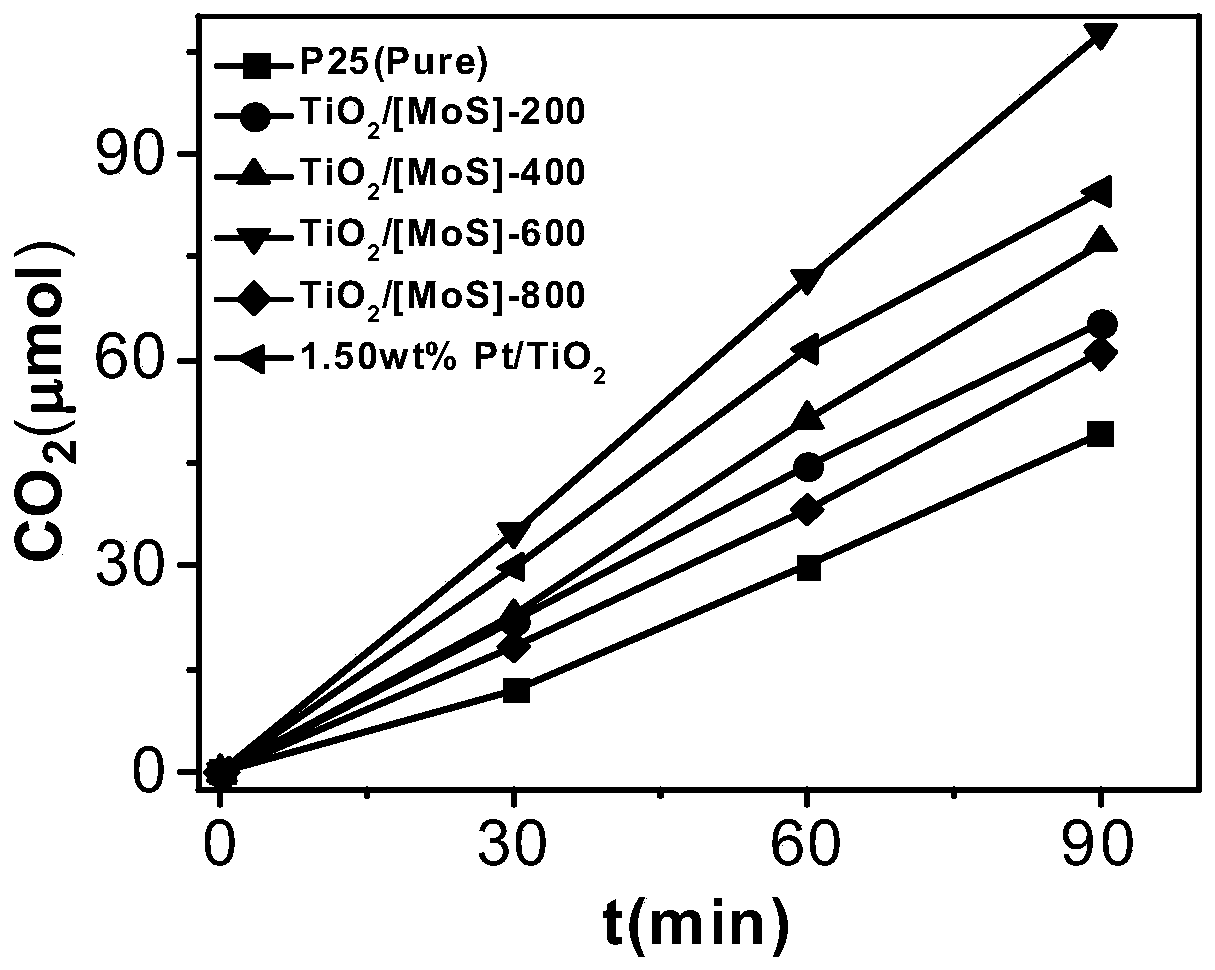

[0042] This embodiment relates to a kind of TiO 2 The preparation of / [MoS] photocatalyst specifically includes the following steps:

[0043] Dissolve 300 mg of P25 in 40 mL of absolute ethanol, add 200 μL of the thiomolybdic acid nanocluster solution prepared in Example 1, and stir at room temperature for 8 h. The obtained solution was centrifuged at 5000 rpm for 2 min to obtain the bottom precipitate and then washed and centrifuged once with water at a rotating speed of 5000 rpm for 2 min. After the bottom precipitate was obtained, anhydrous ethanol was added for washing and centrifugation once, with a rotating speed of 5000 rpm for 2 min. The obtained precipitate was vacuum-dried to obtain TiO 2 / [MoS]-200.

Embodiment 3

[0045] This embodiment relates to a kind of TiO 2 The preparation of / [MoS] photocatalyst is different from Example 2 only in that 400 μL of the thiomolybdic acid nanocluster solution prepared in Example 1 is added to obtain a photocatalyst TiO 2 / [MoS]-400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com