Insulator unloading device

A technology for unloading devices and insulators, which is applied to lifting devices and other directions, can solve the problems of time-consuming and labor-intensive unloading of insulators, and achieve the effect of reducing physical labor and high handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

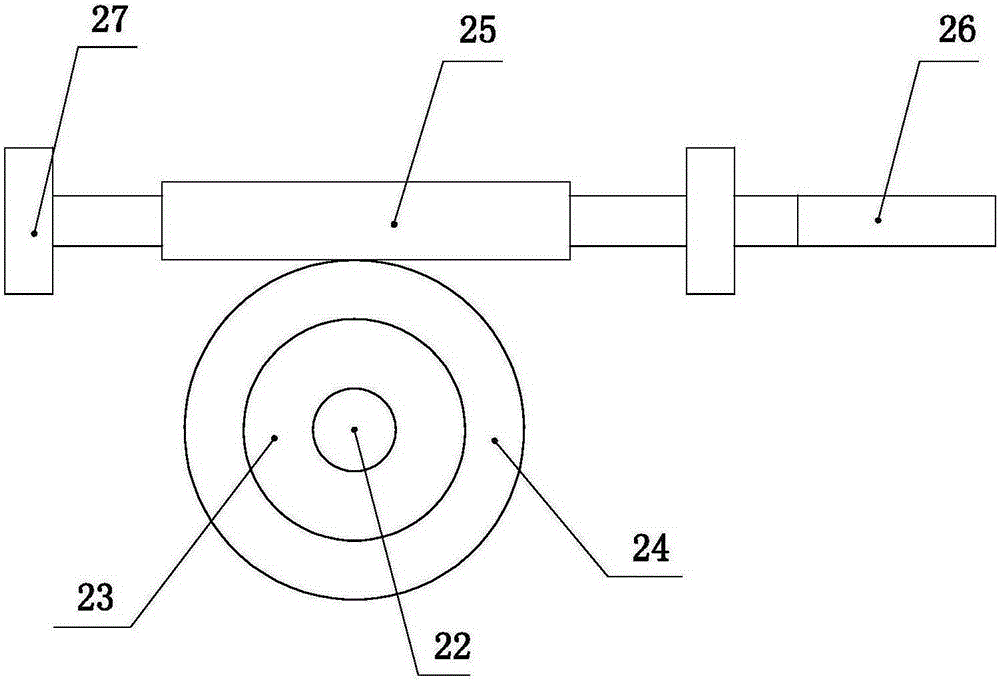

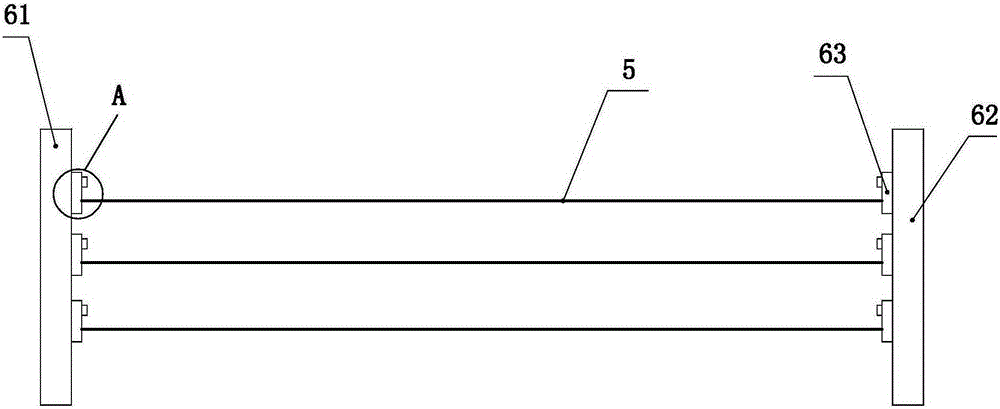

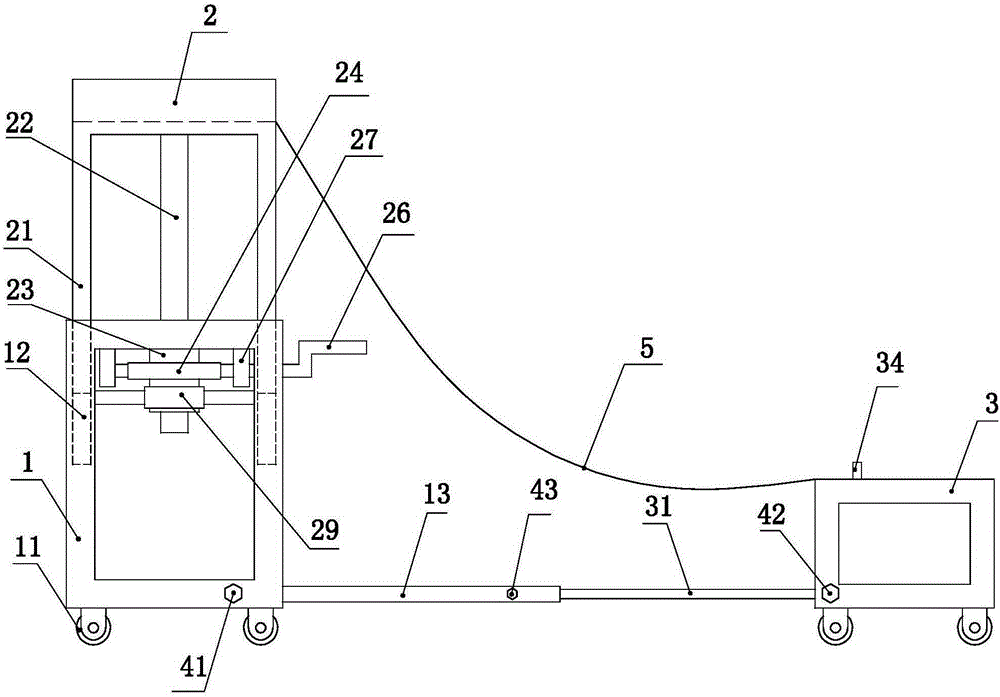

[0024] like Figure 1 to Figure 9 As shown, the present invention includes a first support 1, a roller 11, an outer rod 13, a lifting platform 2, a leg 21, a lead screw 22, a lead screw nut 23, a worm wheel 24, a worm screw 25, a handle 26, a bearing 27, a support rod 28. Bearing 29, second bracket 3, inner rod 31, buffer plate 34, spring 35, first bolt 41, second bolt 42, third bolt 43, fourth bolt 44, lifting rope 5, first beam 61, The second beam 62 and the slider 63 will be described in detail below in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, the first bracket 1 is a welded part of a profile, and is formed into a square structure as a whole. The first bracket is a supporting component, and other components are installed on the first bracket. The bottom of the first bracket is provided with a roller 11, which is a universal wheel. The top of the first support is provided with vertical chute 12, and there are four chute, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com