Intelligent steam hydrophobic valve

A steam trap and steam technology, applied in steam traps, mechanical equipment, etc., to achieve high heat exchange efficiency and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

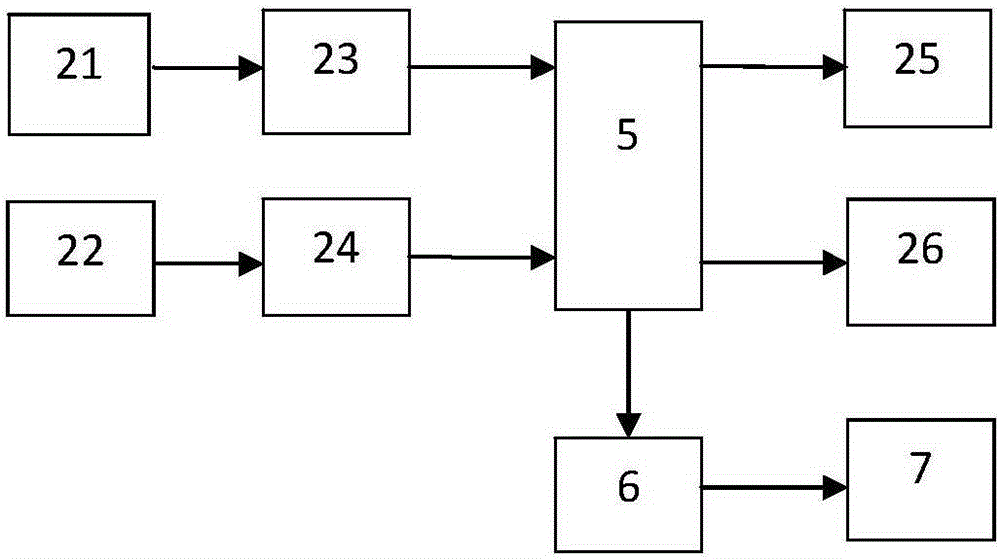

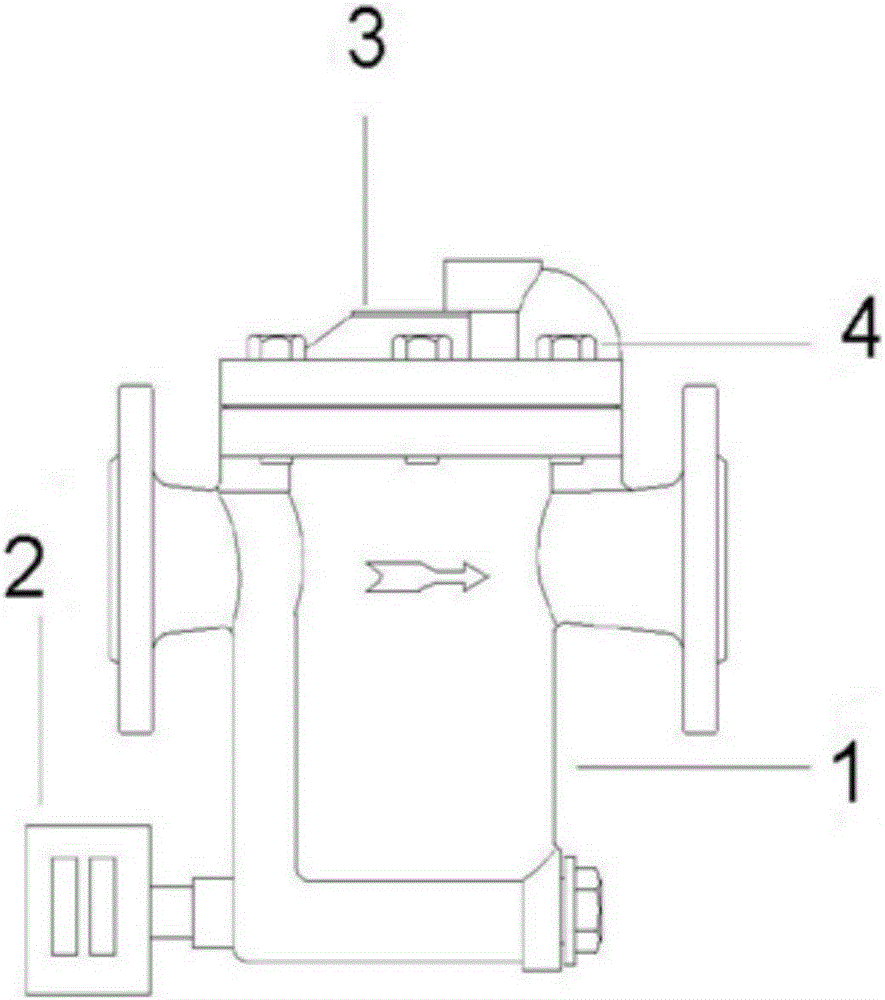

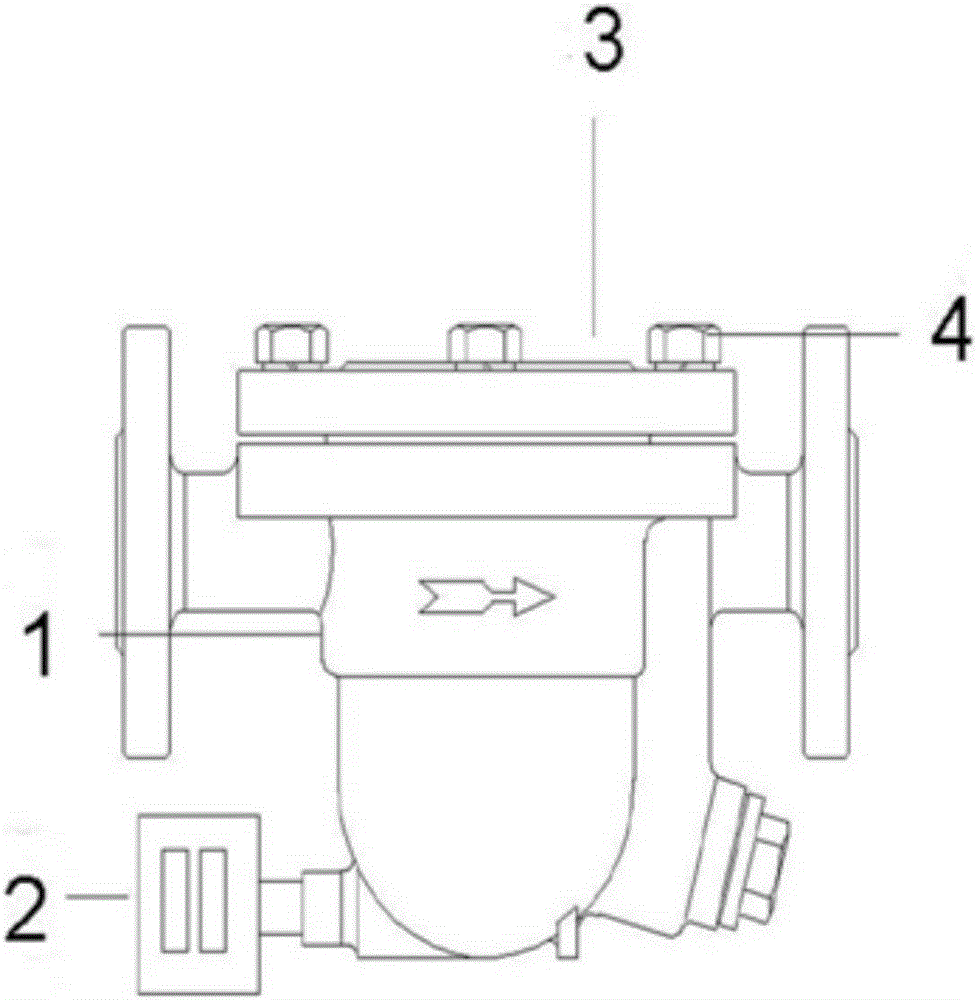

[0021] see Figures 1 to 7 , the embodiment of the present invention is provided with a valve body 1, a valve cover 3, bolts and nuts 4, an intelligent device 2, a control circuit 5, a communication module 6 and a computer 7; the intelligent device 2 is provided with a pressure sensor 21, a temperature sensor 22, a pressure The signal amplifier 23, the temperature signal amplifier 24, the digital display circuit 25 and the alarm circuit 26; the pressure sensor 21 and the temperature sensor 22 are arranged in the lower part of the valve body 1 to detect the pressure and temperature of the condensed water in the lower part of the valve body 1, and the pressure sensor 21 The output end of the temperature sensor 22 is connected to the input end of the pressure signal amplifier 23, the output end of the pressure signal amplifier 23 is connected to the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com