Novel down lead wire clamp

A down conductor clip and a new type of technology are applied in the field of improvement of down conductor clips for overhead optical cables, which can solve the problems of reduced installation quality, small contact area, deformation of openings, etc., and achieve improved reliability, good adaptability, and easy selection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

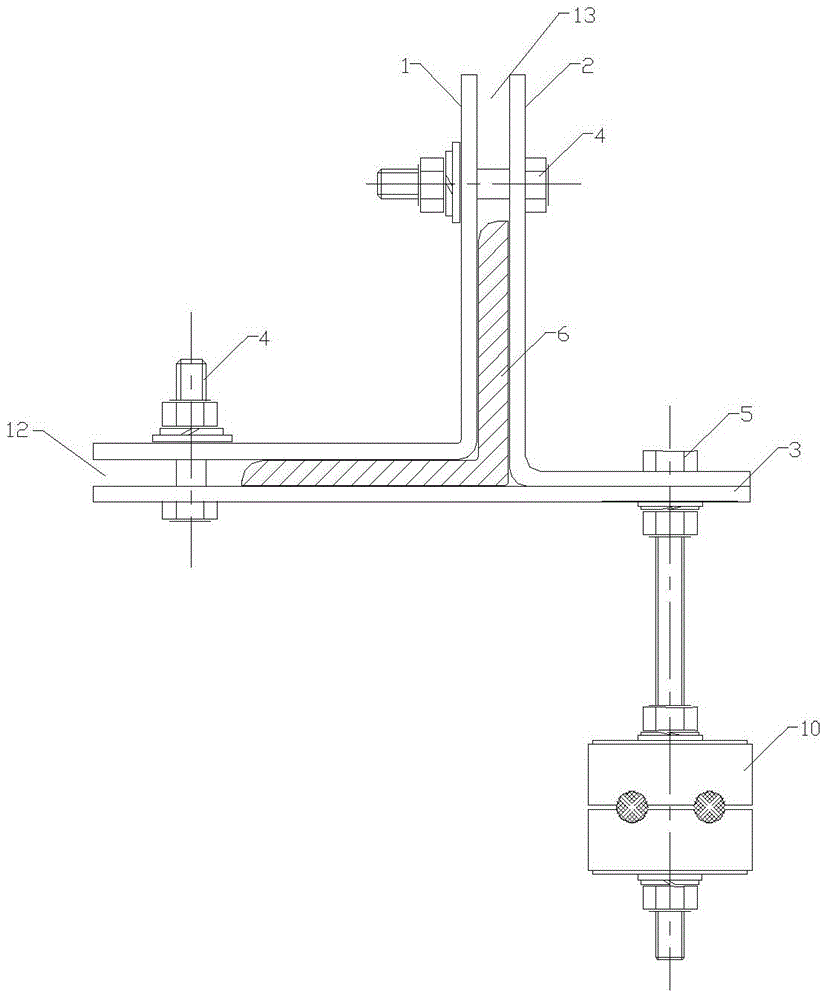

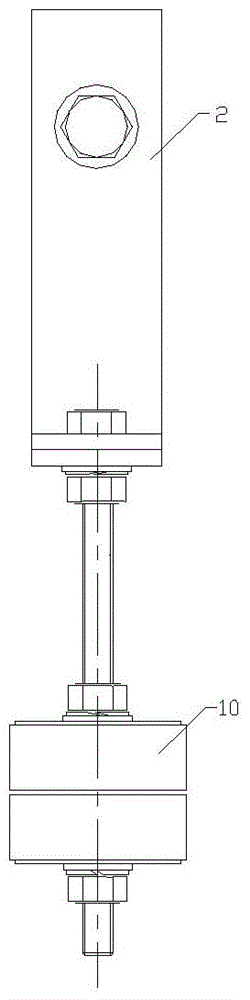

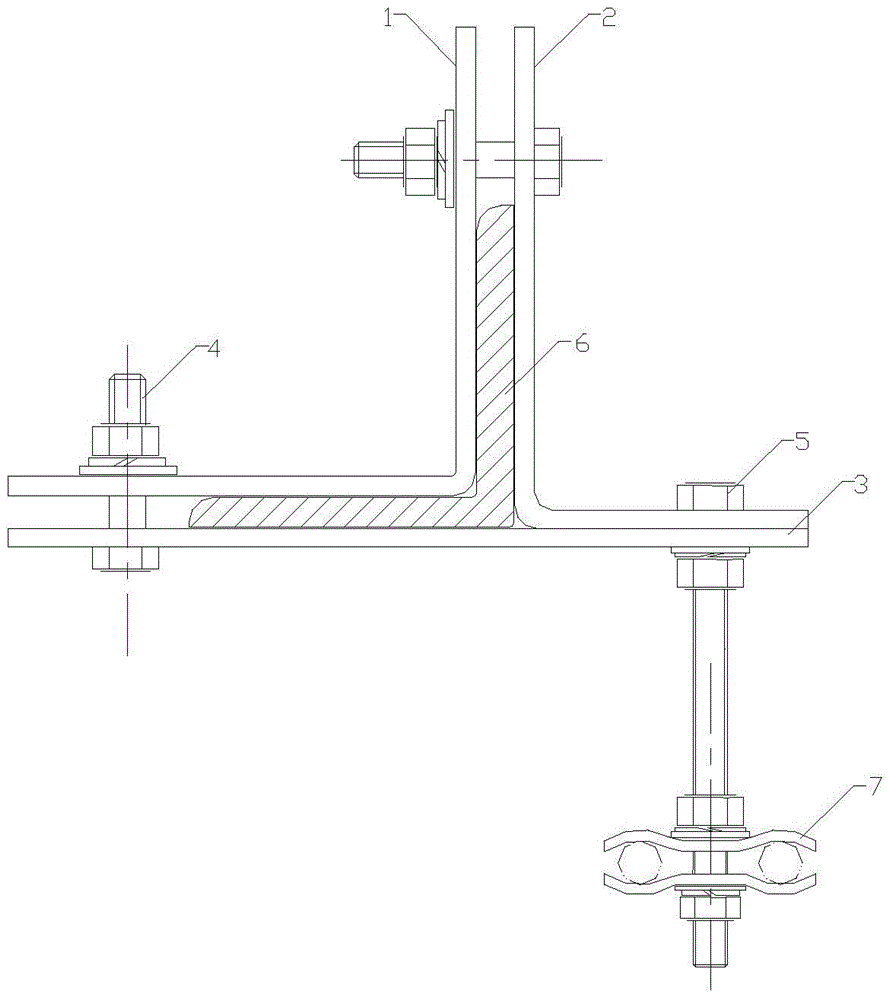

[0025] The invention is like Figure 1-6 As shown, it includes an installation splint and a cable clamp. The installation splint includes a left splint 1, a right splint 2 and a straight splint 3. The left splint 1 and the right splint 2 are L-shaped and have a horizontal plate and a vertical plate. , The straight splint 3 is plate-shaped;

[0026] The horizontal plates of the left splint 1 and the right splint 2 are respectively arranged outwards (toward the outside of the respective vertical plates) and are respectively parallel to the straight splint 3, and the horizontal plates of the left splint 1 are connected by fastening bolts 4 On the straight splint 3, the horizontal plate of the right splint 2 is connected to the straight splint 3 by a long bolt 5, and a horizontal accommodation space 12 is provided between the left splint 1 and the straight splint 3;

[0027] The vertical plates of the left splint 1 and the right splint 2 are parallel to each other and are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com