A Prediction Method for Rolling Bearing Performance Retention Reliability

A rolling bearing and prediction method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of predicting the variation process and different thresholds that cannot be used for the performance reliability of rolling bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The prediction method of the rolling bearing performance maintenance reliability of the present embodiment 1 comprises the following steps:

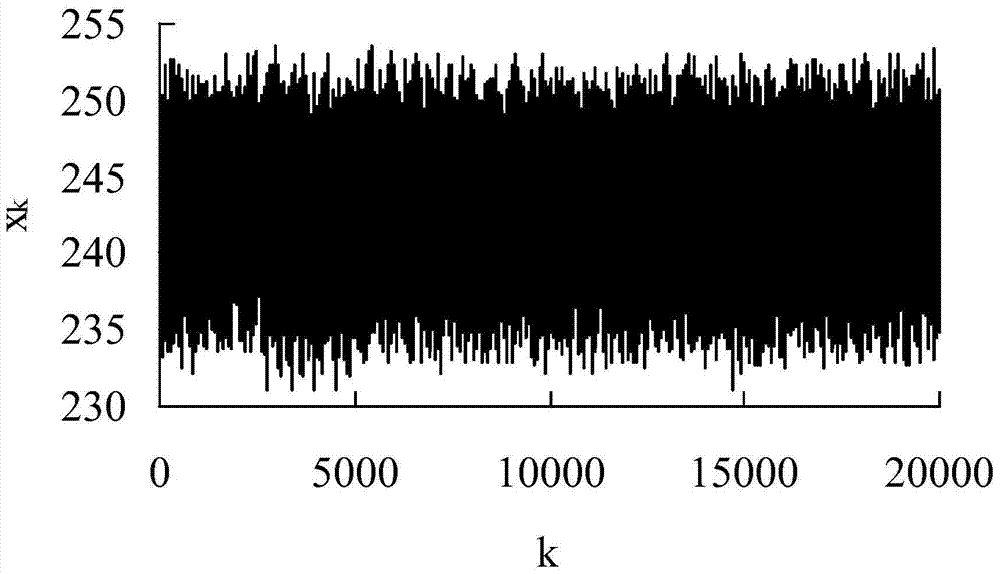

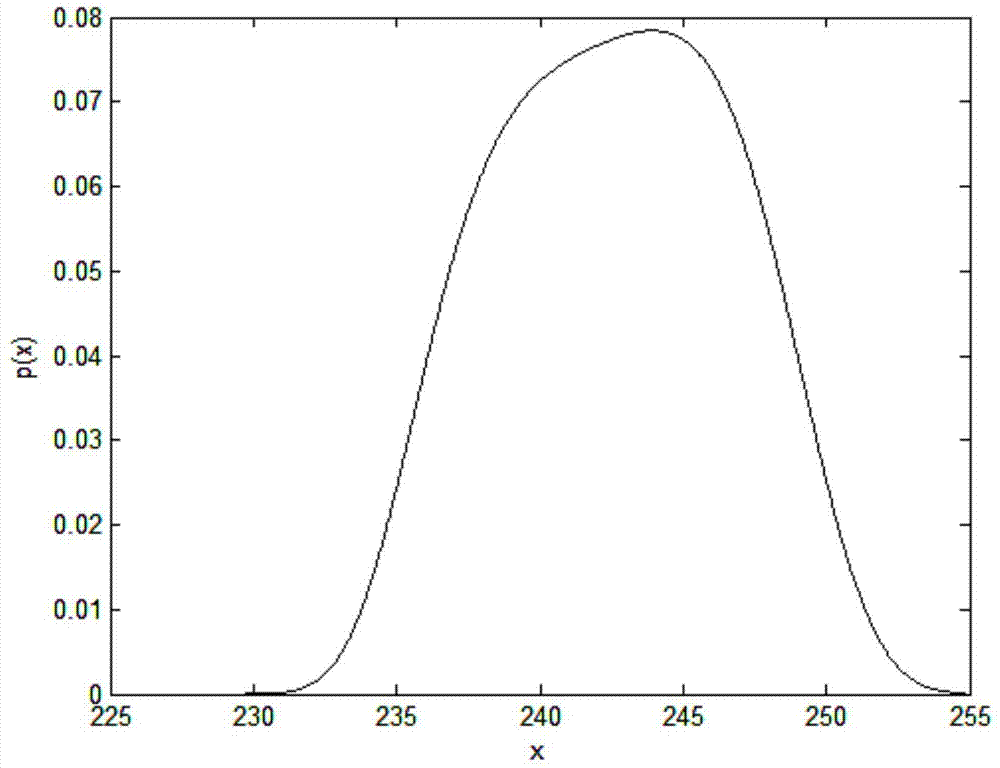

[0074] 1) During the best period of rolling bearing operation performance, the friction torque of the rolling bearing in the evaluation time interval is regularly measured by the measurement system, and K performance data of the friction torque are obtained at the current time t=1, K=20000, the kth performance data for x k , k=1, 2,..., 20000, the data unit is N m; the distribution diagram of the obtained rolling bearing friction torque data is as follows figure 1 shown;

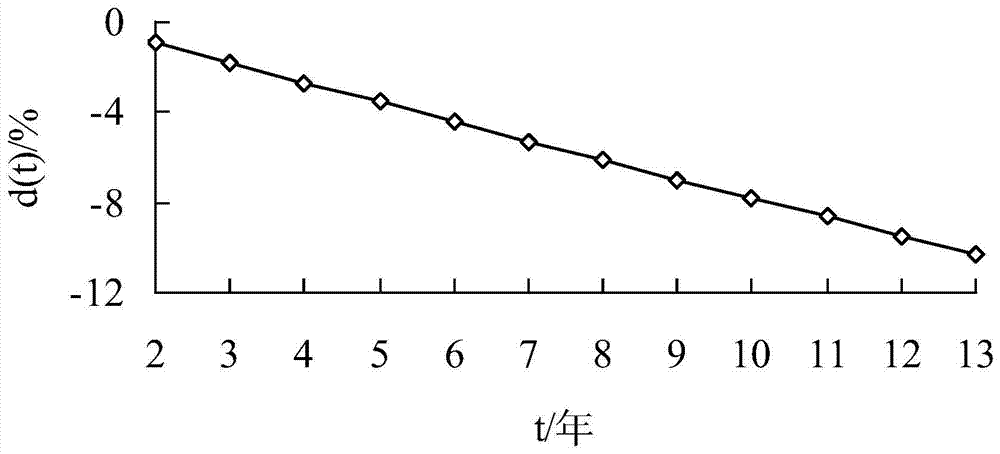

[0075] In this embodiment 1, the evaluation time interval is 1 year, each prediction time interval is 1 year, and the unit of time t is year; the rolling bearing performance maintenance reliability prediction method of this embodiment is used to predict the failure of the rolling bearing friction torque performance the time course of the degree in a future tim...

Embodiment 2

[0123] The prediction method of the rolling bearing performance maintenance reliability of the present embodiment 2 comprises the following steps:

[0124] 1) During the best period of rolling bearing operation performance, the vibration acceleration of the rolling bearing in the evaluation time interval is regularly measured by the measurement system, and at the current time t=1, K performance data of vibration acceleration are obtained, K=20000, the kth performance data for x k , k=1, 2, ..., 20000, the data unit is μm / s 2 ; The distribution diagram of the obtained rolling bearing vibration acceleration data is as follows Figure 4 shown;

[0125] In this embodiment 2, the evaluation time interval is 1 year, each prediction time interval is 1 year, and the unit of time t is year; the rolling bearing performance maintenance reliability prediction method of this embodiment is used to predict the failure of the rolling bearing vibration acceleration performance the time cour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com