Oil layer simulation processing method

A technology for simulating processing and oil layers, which is applied in the field of plane simulation experiments in the oil reservoir exploitation industry, can solve the problems that the core resources cannot meet the characteristics of the oil layers, and the simulation degree of the real situation of the oil layers is not high enough, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

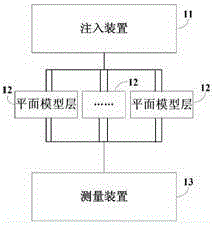

[0057] Such as figure 1 As shown, the system used in the method of the present invention includes: an injection device, a plurality of planar model layers and a measuring device; wherein,

[0058] Injection device 11, used for injecting displacement fluid into multiple planar model layers 12;

[0059] A plurality of planar model layers 12 are packaged with natural low-permeability sandstone flat plates with different geometric dimensions and well pattern types and different permeability, and a plurality of boreholes or wellbores penetrating through each planar model layer are formed in the planar model layers , simultaneously forming a plurality of perforations (not shown) by the above-mentioned secondary detonation method, for simulating each plane of a multi-layer reservoir;

[0060] Among them, pressure measurement points are arranged on the front of each plane model layer 12 for measuring the pressure field of each plane model layer 12, and electrode measurement points ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com