Tea leaf unraveling machine

A deblocking machine and tea technology, which is applied in the field of tea processing equipment, can solve the problems of unobvious tea breaking effect and incomplete cleaning of tea powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

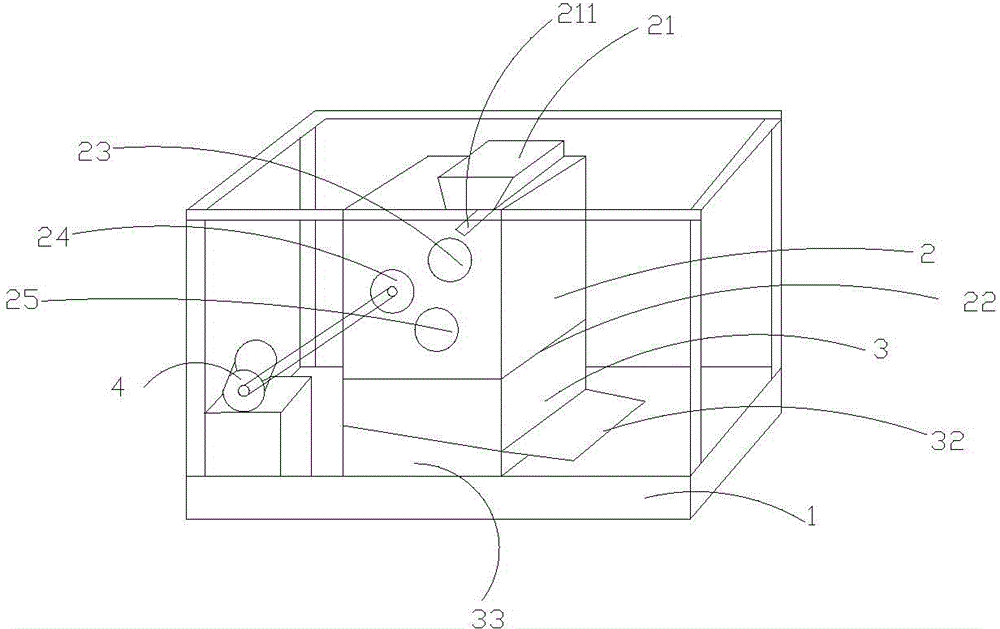

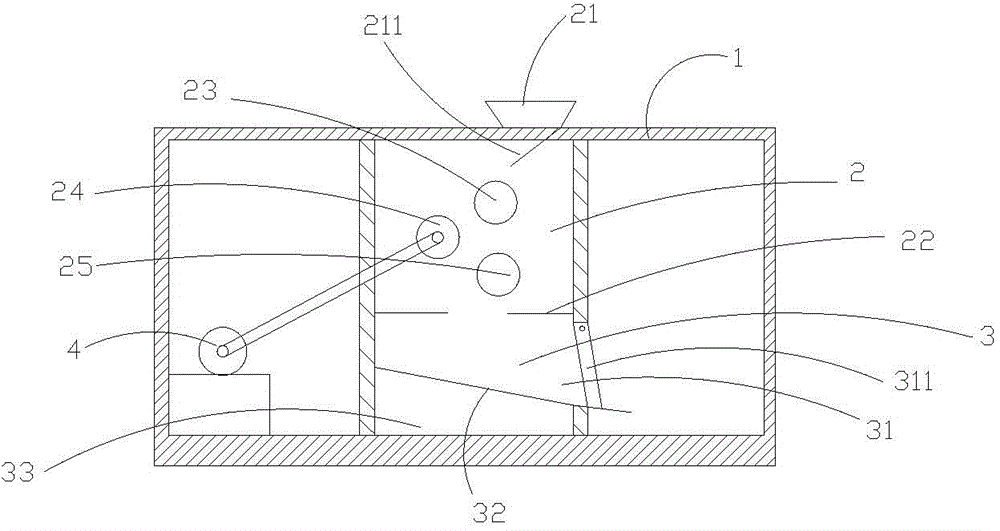

[0016] Such as figure 1 As shown, a tea deblocking machine includes a frame 1, a deblocking bin 2 arranged on the frame 1, a collection bin 3, and a driving device 4. The upper end of the deblocking bin 2 is provided with a feed port 21, and the collection The side of feed bin 3 is provided with discharge port 31, and discharge port 31 place is provided with the closed baffle plate 311 that is used to close discharge port 31, and the upper end hinge of closed baffle plate 311 is connected on the side of collection bin 3, can conveniently When the discharge port is closed, a hollow baffle 22 is provided between the unblocking bin 2 and the collecting bin 3 . The deblocking chamber 2 is successively provided with three cooperating first decomposing wheels 23, the second decomposing wheel 24, and the third decomposing wheel 25 from top to bottom. The axis midpoints of the three decomposing wheels form an acute triangle, and the second The distance from the axis center of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com