Preparation method of composite magnetic algaecide

A composite magnetic algaecide technology, which is applied in chemical instruments and methods, mixers, magnetic/electric field water/sewage treatment, etc., can solve the problem of inability to prepare magnetic algaecide, achieve good block removal effect, and accelerate drainage Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

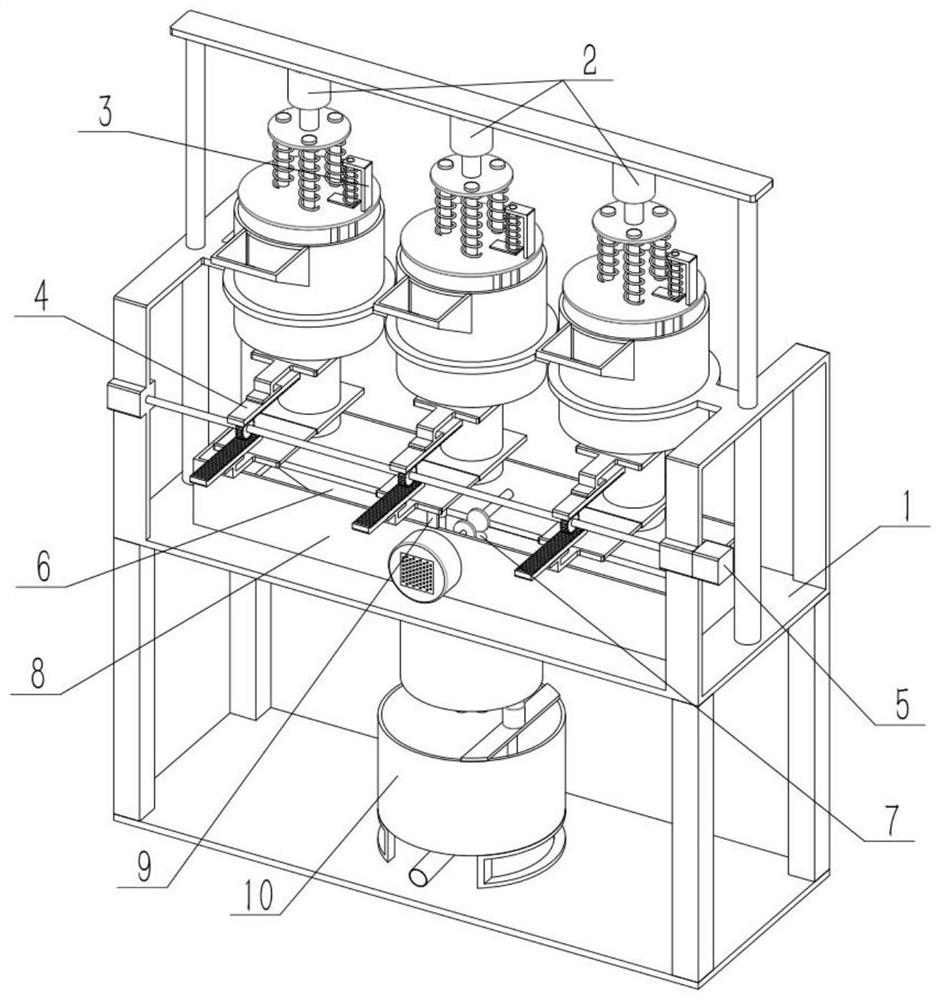

[0040] As shown in the figure, a preparation method of a composite magnetic algicide comprises the following steps:

[0041] Step 1, put three kinds of raw materials of polyaluminum ferric chloride, magnetite powder and ferric sulfate into the preparation device of composite magnetic algicide;

[0042] Step 2, after deblocking the three raw materials respectively, carry out proportioning to obtain the proportioned raw materials;

[0043]Step 3, uniformly mixing the proportioned raw materials to obtain powdery raw materials;

[0044] Step 4, mixing powdery raw materials with water to prepare a composite magnetic algaecide;

[0045] The preparation method of the above-mentioned composite magnetic algaecide also includes a preparation device of the composite magnetic algaecide;

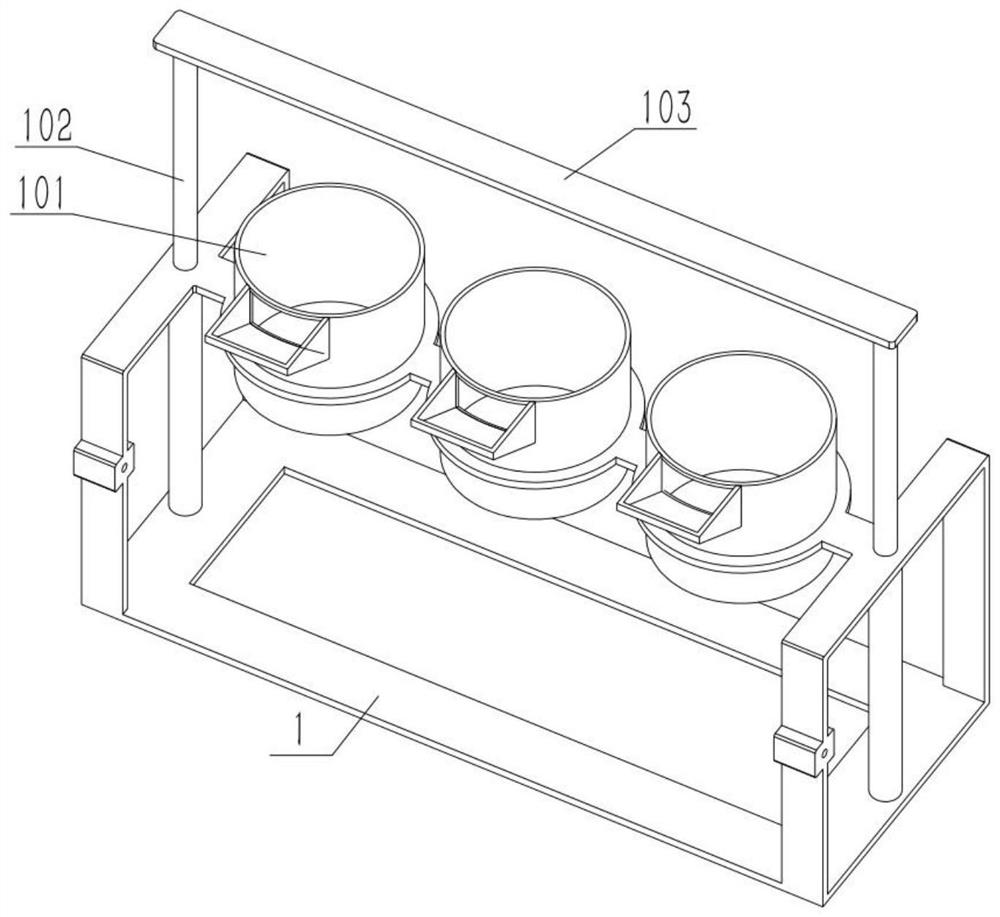

[0046] The preparation device of the composite magnetic algaecide comprises a frame 1, a bucket 101, an electric push rod 102, a top platform 103 and a fragmenter 2, and the upper end of the frame 1 is...

specific Embodiment approach 2

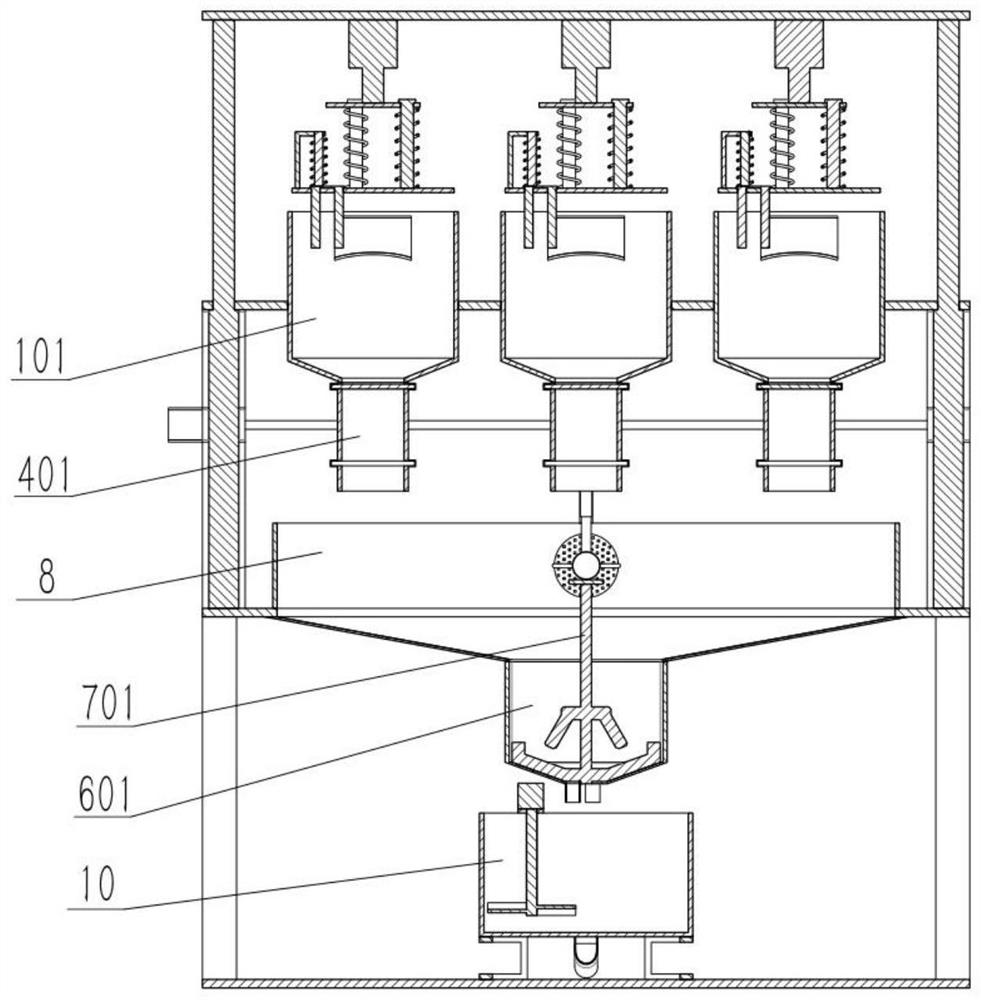

[0048] As shown in the figure, the breaker 2 also includes a stress rod I202, a base plate 203 and a motor I204. The upper end of the fragment plate 201 is uniformly fixed to three force rods I202 in the circumferential direction, and the base plate 203 is slidably connected to three On each stress rod I202, the upper end of each stress rod I202 is affixed to the limit part, and the lower end surface of the limit part is attached to the upper end surface of the base plate 203, and each force rod I202 is covered with Compression spring I, the upper and lower ends of the compression spring I are in contact with the base plate 203 and the fragment plate 201 respectively, the output shaft of the motor I204 is fixedly connected to the upper end of the base plate 203, and the motor I204 is fixedly connected to the top platform 103; The preparation device of the composite magnetic algaecide also includes a dredge 3, and the dredge 3 includes a base plate 301, a dredging plate 302, a f...

specific Embodiment approach 3

[0050] As shown in the figure, the preparation device of the composite magnetic algaecide also includes a proportioner 4, a motor II 5 and a gear 501, and the proportioner 4 includes a proportioning tube 401, an upper wall bin 402, an upper sealing plate 403, an upper connection Seat 404, upper rack 405, lower wall bin 406, lower sealing plate 407, lower connecting seat 408 and lower rack 409, the upper and lower sides of the proportioning pipe 401 are respectively provided with integrally connected upper wall bin 402 and lower wall bin 406, the upper sealing plate 403 and the lower sealing plate 407 are slidably connected in the upper wall bin 402 and the lower wall bin 406 respectively, and the upper connecting seat 404 and the lower connecting seat 408 are fixedly connected to the back of the upper sealing plate 403 and the lower sealing plate 407 respectively. end, the rear ends of the upper sealing plate 403 and the lower sealing plate 407 are fixedly connected to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com