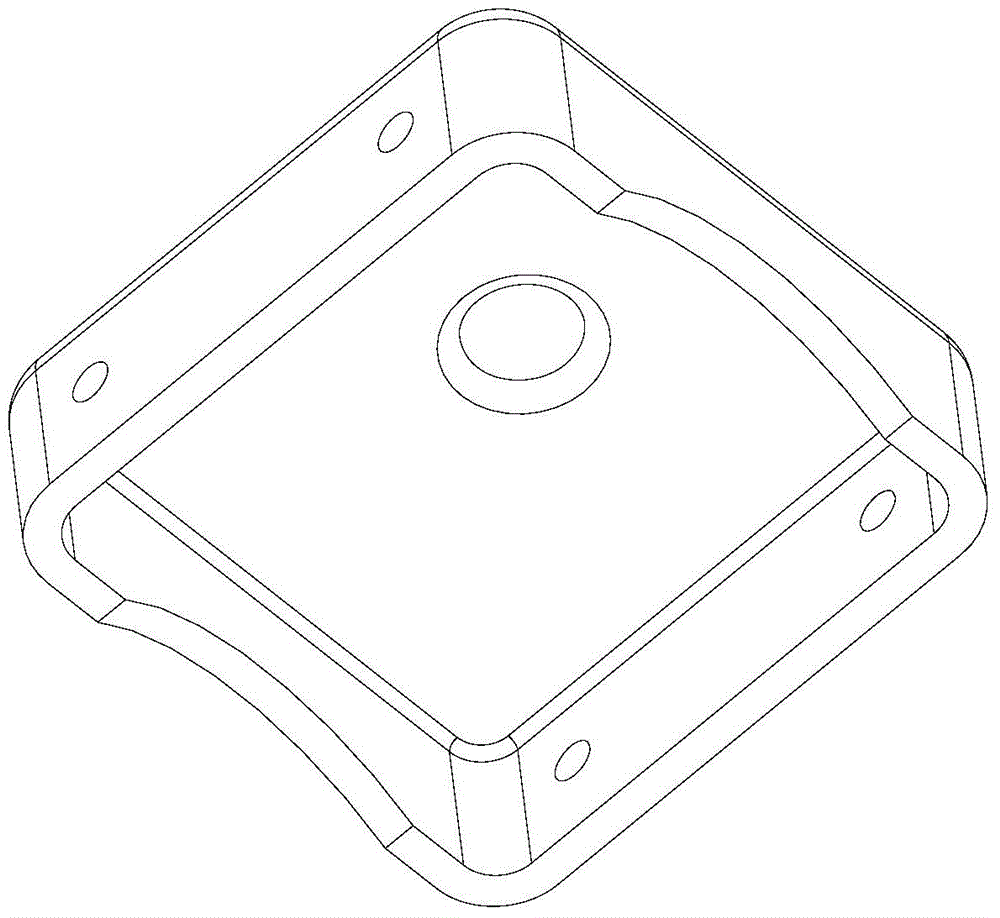

Riveting pin clamp for lock tongue cover plate

A cover plate and riveting pin technology, which is applied in the field of assembly aids for automobile switches, can solve problems such as time-consuming and labor-intensive fixtures, and achieve the effects of improving riveting efficiency, avoiding operation accidents, and improving riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

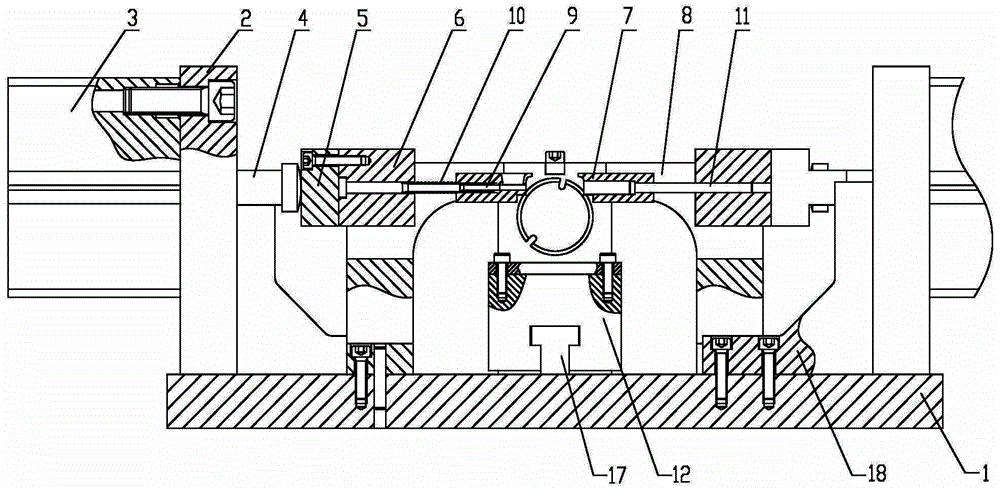

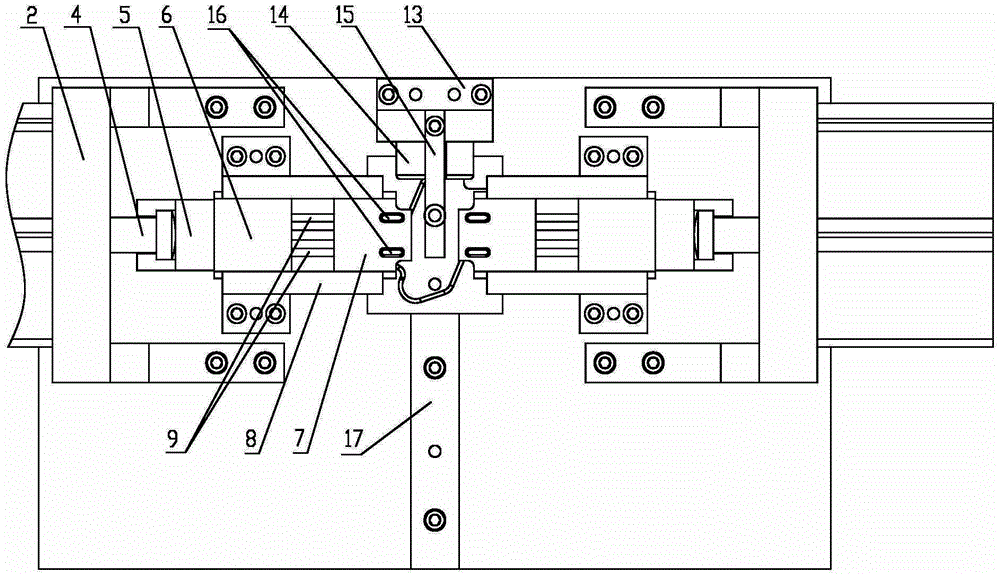

[0021] Please also refer to Figures 2 to 3 , a riveting fixture for a deadbolt cover plate, comprising a bottom plate 1, a cylinder fixing plate 2, a cylinder 3, a cylinder connecting shaft 4, a floating joint 5, a punch fixing block 6 and a preloading block 7.

[0022] Wherein, the central position of base plate 1 is provided with positioning block 12, and positioning block 12 is provided with the mold cavity that is used for placing deadbolt cover plate, is also provided with guide plate 17 between positioning block 12 and base plate 1, and positioning block 12 bottom is provided with The groove matched with the guide plate 17, the above-mentioned positioning block 12 can move on the guide plate 17. On the base plate 1, a vertical plate 13 is fixed near the rear side of the positioning block 12, and the vertical plate 13 is provided with a hole, and a positioning shaft 14 is installed in the hole, and the top of the vertical plate 13 is also fixed with a pressing plate 15. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com