Automobile hinge installation clamp

A technology for installing fixtures and hinges, applied to auxiliary devices, vehicle parts, manufacturing tools, etc., to solve the problem of fit clearance and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

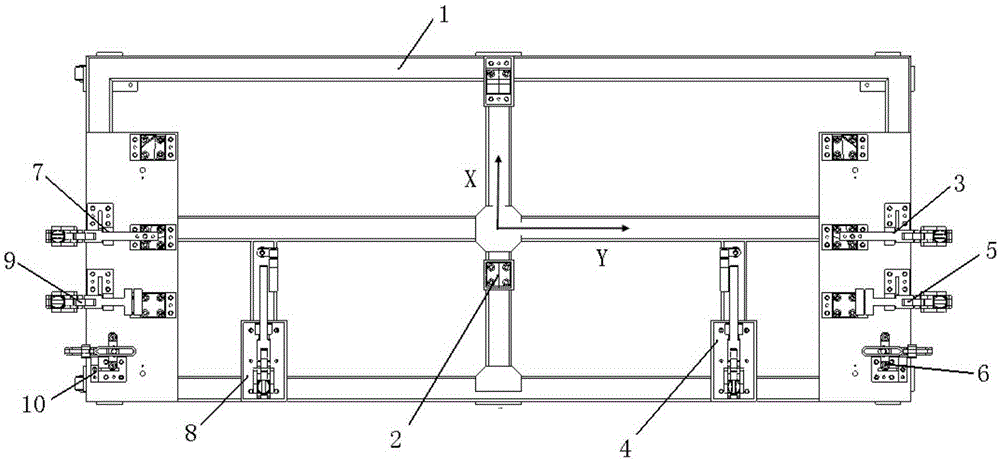

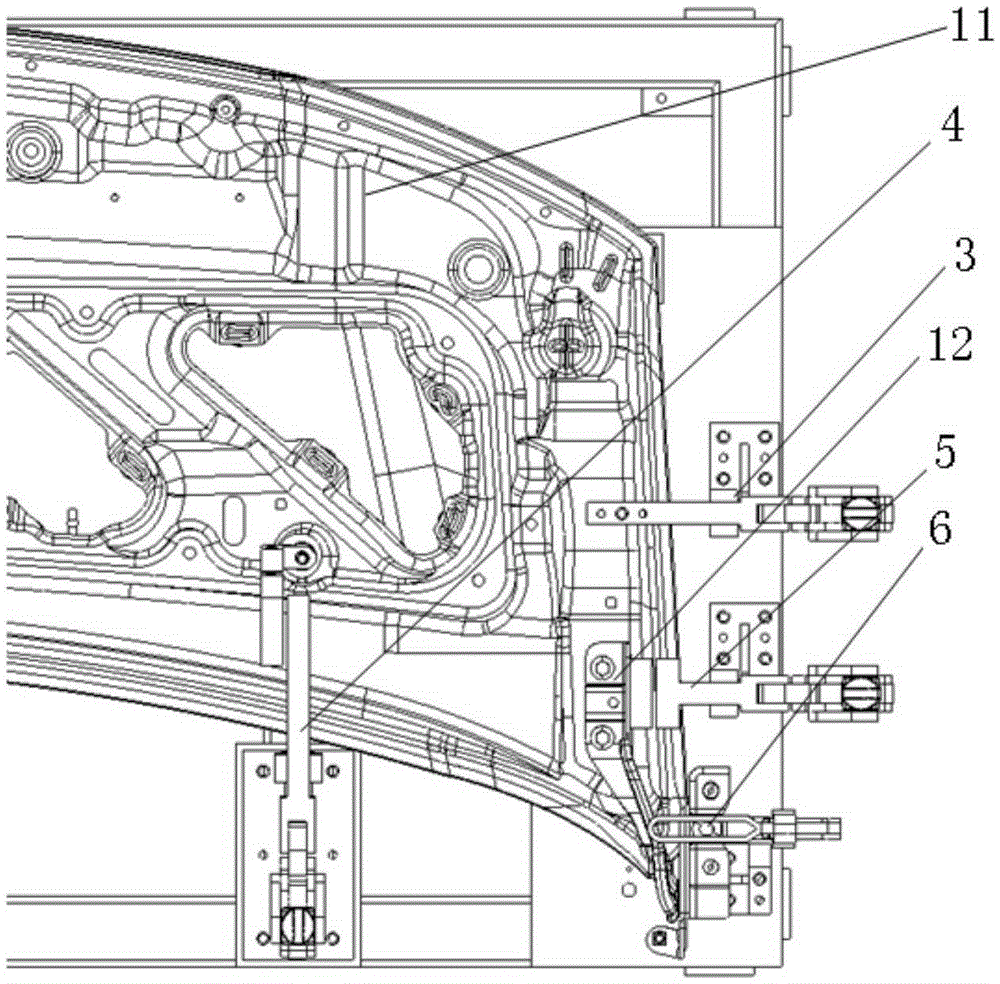

[0033] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0034] The invention first installs the hinge and the engine cover through the fixture offline, and then installs the hinged engine cover on the vehicle body, reducing one installation station on the line and solving the problem of the rhythm of assembly and adjustment on the line.

[0035] The fixture of the present invention is designed as a positioning type, which ensures that the position of the hinge installed on the engine cover is fixed and unique, and solves the problem of manual adjustment; through the debugging of the craftsman, find the theoretical value suitable for the matching gap between the engine cover and the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com