An automatic container track hanging eight ropes on the shelf

A rail crane and container technology, applied in the field of anti-sway hangers, can solve the problems of shortening the service life of steel wire ropes, broken wires, etc., and achieve the effects of prolonging service life, long service life and alleviating radial impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

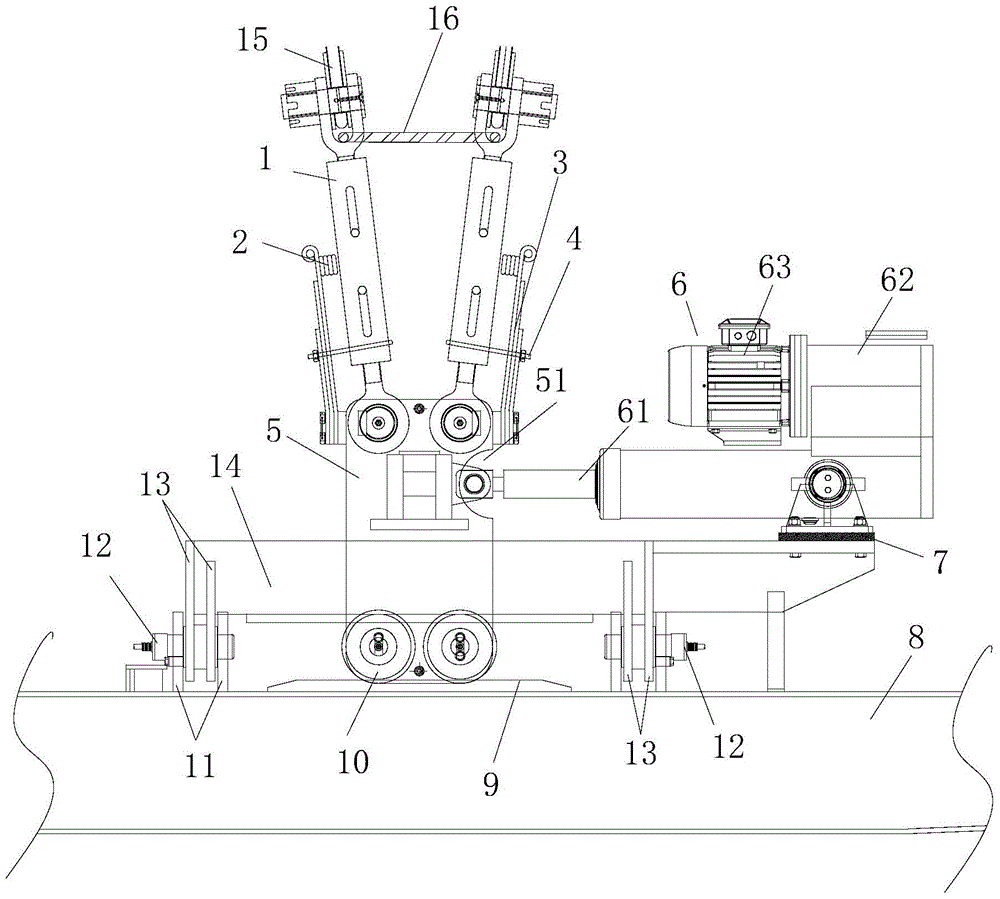

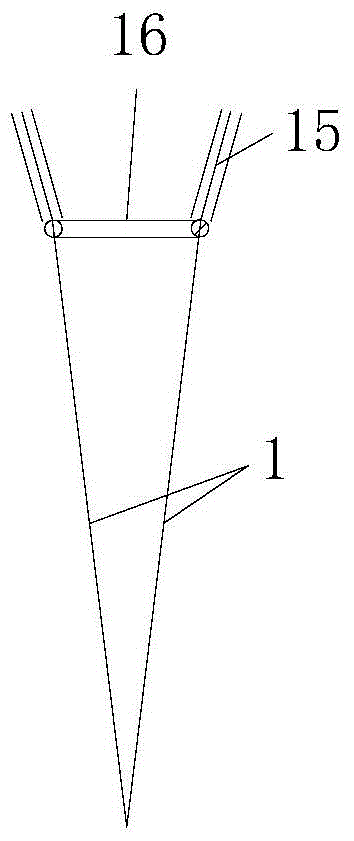

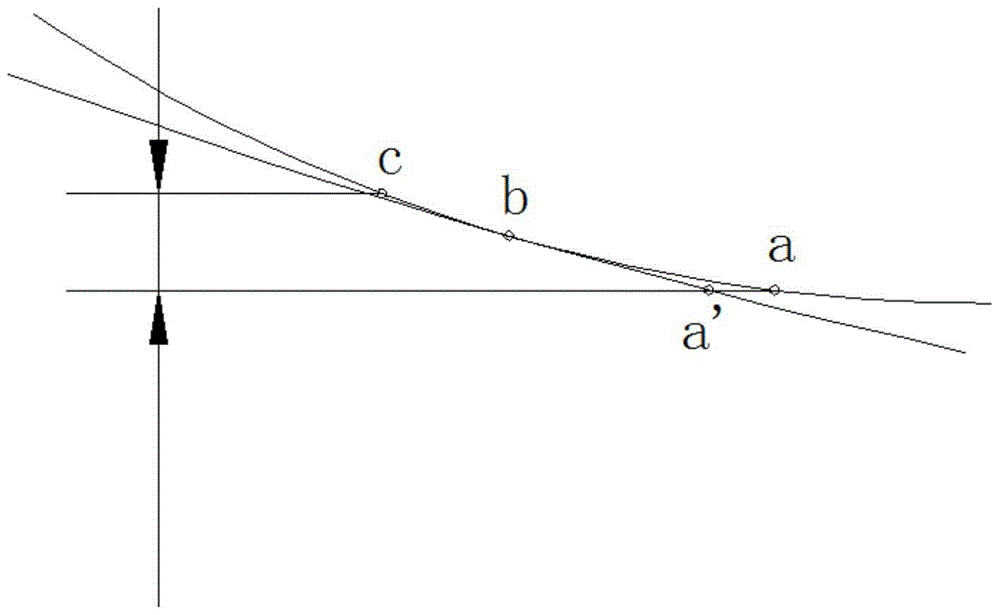

[0030] Such as figure 1 and figure 2 As shown, a kind of automatic container rail hangs eight ropes and puts on the shelf, comprises the shelf base, and the shelf base includes four crossbeams 8, and the top of every crossbeam 8 is all provided with the first guide rail 14, can slide along the first guide rail 14 Moving plate 5, a driving mechanism for driving the moving plate 5 on the crossbeam 8 to do linear motion, the top of each moving plate 5 is provided with a hoisting portion, and each hoisting portion includes two separate turnbuckles 1 and is arranged on each The hoisting wire rope 15 at the top of each turnbuckle 1, the bottom end of each turnbuckle 1 is connected with the moving plate 5, and the tops of the two turnbuckles 1 belonging to the same lifting part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com