Balanced valve and crane using same

A technology for balancing valves and valve cores, applied in cranes, mechanical equipment, fluid pressure actuation devices, etc., to solve problems such as damage to hydraulic components, user discomfort, structural vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

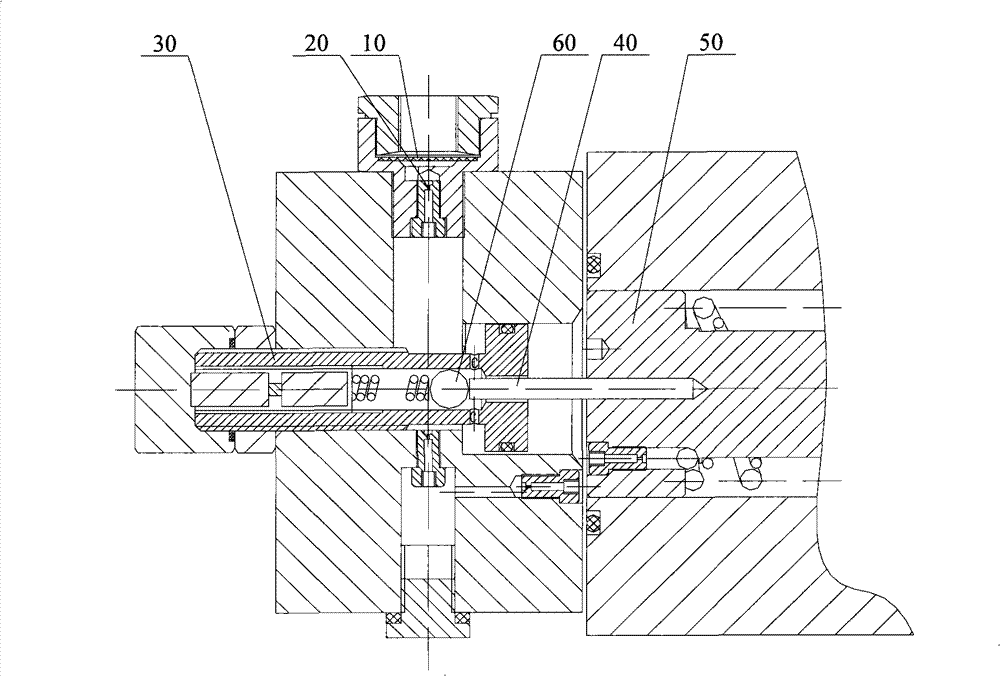

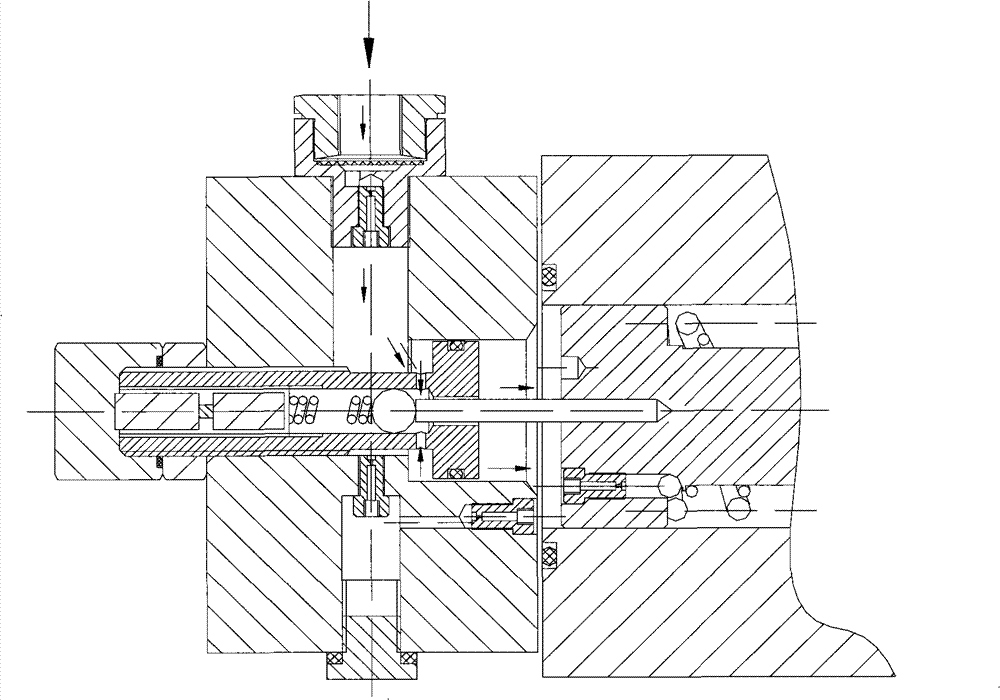

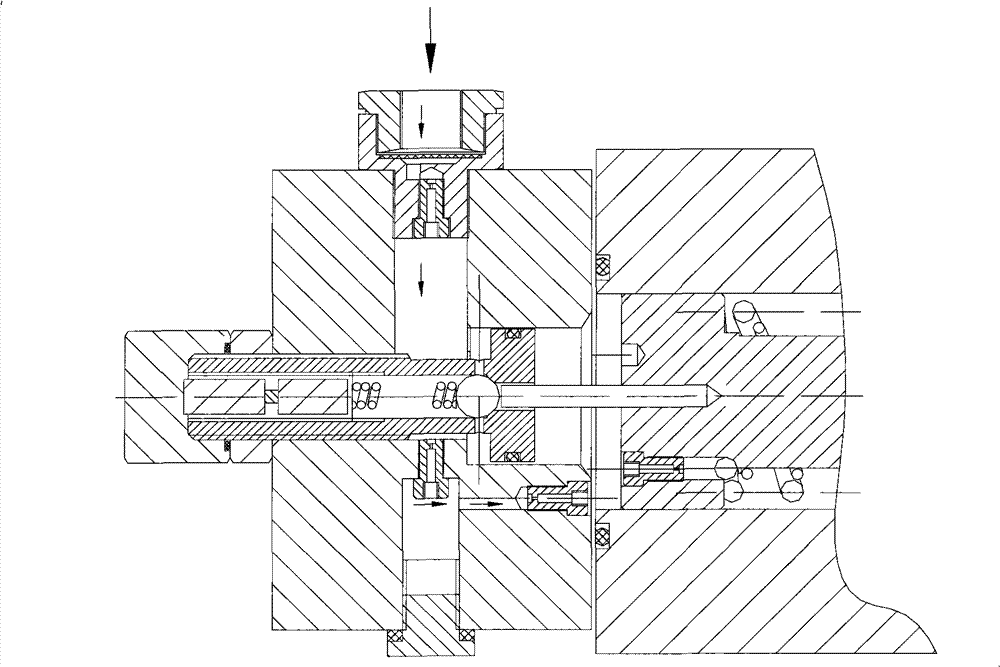

[0031] Based on the prior art, there are two control oil passages between the control oil port of the valve body of the balance valve provided by the present invention and the chamber at the end of the spool, and the first oil passage has a plugging component and is linked with the spool. The ejector rod; the control oil enters the chamber through the hole between the ejector rod and the first oil passage, and the plugging part moves with the ejector rod and after the end of the plug seals the hole, the control oil The liquid enters the chamber through the second oil passage; the key point of the design is that there is a throttling groove on the end mating surface of the plugging part matched with the hole, and the cross-sectional area of the throttling groove is along the The axial direction gradually decreases, so that when the mating surface gradually approaches the pore until it is blocked, the flow rate through the pore decreases gradually, so as to avoid hydraulic shoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com