A turntable assembly for a three-dimensional garage

A three-dimensional garage and turntable technology, which is applied to buildings where cars are parked, building types, buildings, etc., can solve the problem that the turntable assembly cannot be centered and corrected, and save equipment energy consumption, reduce starting resistance, and reduce equipment. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

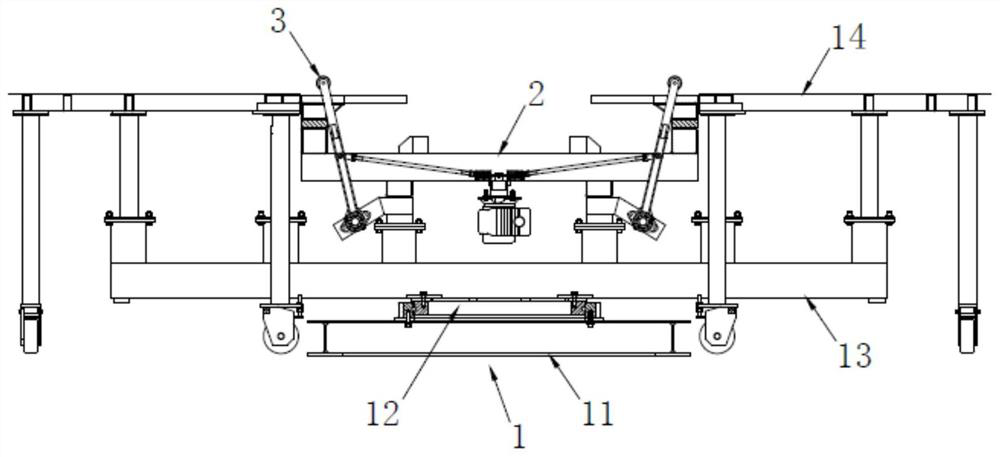

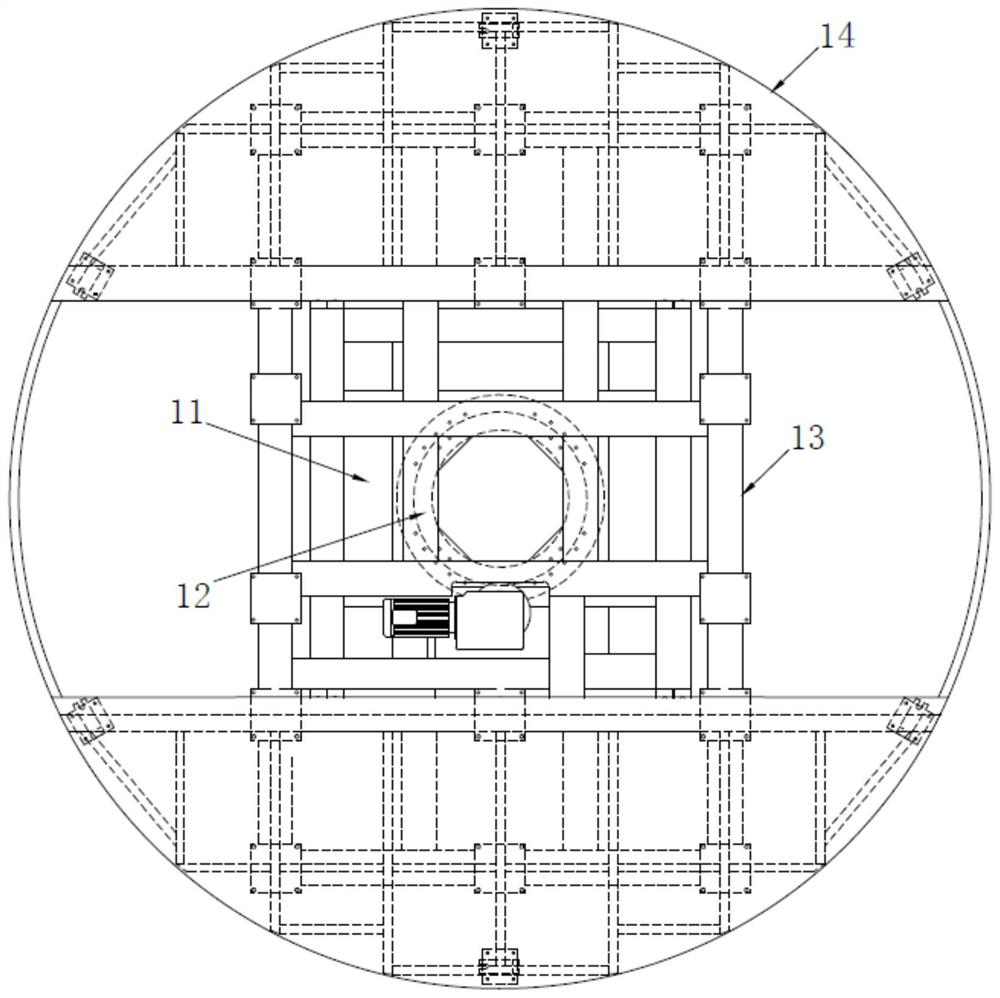

[0070] This embodiment provides a turntable assembly for a three-dimensional garage, such as figure 1 As shown in , it includes a turntable device 1, a car frame 2 and a centering device 3 for correcting vehicle alignment; the car frame 2 is installed in the middle of the turntable device 1, and is driven by the turntable device 1 to rotate horizontally; the The centering device 3 is installed on the car frame 2. When parking and warehousing, the warehousing vehicle is transported into the turntable assembly by the comb-tooth trolley, and transferred to the car frame 2. On the car frame 2, the centering device 3 is used to squeeze the front and rear of the warehousing vehicle from both sides of the car frame 2. wheels, so that the vehicles entering the warehouse can be moved to the center position of the car frame 2, so as to realize the centering correction of the vehicles.

[0071] Refer below Figure 1 to Figure 10 Shown in, concrete description is given to the turntable ...

Embodiment 2

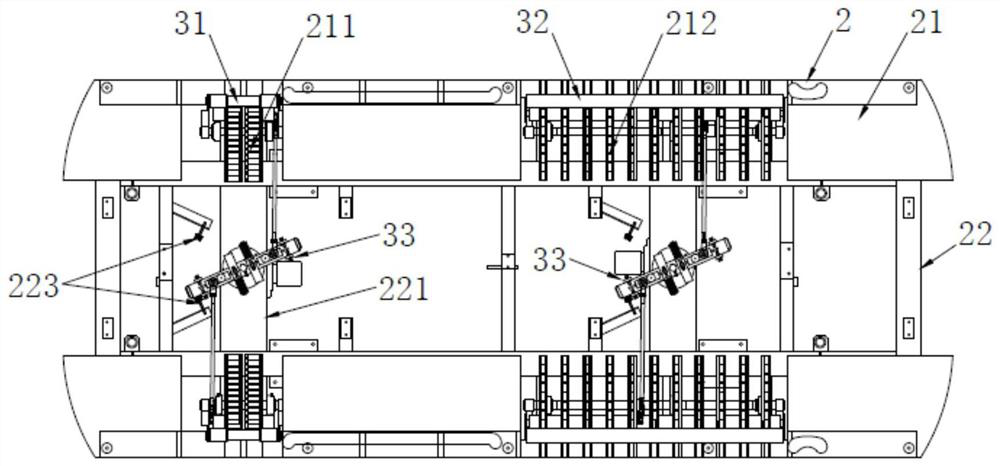

[0076] The basic structure of the turntable assembly for the three-dimensional garage in this embodiment is the same as in Embodiment 1, and the improvement lies in the structure of the centering device 3, refer to Figure 3 to Figure 7 As shown in , the specific description is as follows:

[0077] The driving mechanism 33 includes a motor 331 , a rotary assembly 332 and two main connecting rods 333 . The bottom of the car bottom frame 22 is provided with a motor installation beam 221, the motor 331 is installed on the corresponding motor installation beam 221, and the output shaft of the motor 331 is vertically upward; the rotary assembly 332 is vertically installed on the output shaft, And the two ends of the rotary assembly 332 extend symmetrically to both sides of the output shaft; the opposite ends of the two main connecting rods 333 are respectively movably connected to the rotary assembly 332, and the connection points are respectively located on both sides of the outpu...

Embodiment 3

[0082] The basic structure of the turntable assembly for the three-dimensional garage in this embodiment is the same as in Embodiment 2, and the improvement lies in the structure of the rotary assembly 332, refer to Figure 8 to Figure 10 As shown in , the specific description is as follows:

[0083] The swivel assembly 332 includes a main swivel member 3321 and two floating connection mechanisms. The main rotating member 3321 is maintained in a horizontal state, and the main rotating member 3321 is vertically installed on the output shaft of the motor 331 and extends symmetrically to both sides of the output shaft; two floating connection mechanisms are arranged on the upper side of the main rotating member 3321, And the two floating connection mechanisms are center-symmetric around the output shaft.

[0084] Each of the floating connection mechanisms includes a support 3322 , a bolt 3323 with a washer, a spring 3325 , a secondary rotating member 3324 and two blocking member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com