Method for preparing low-VOC (Volatile Organic Compound) high-solid-content polyurea anticorrosive primer

An anti-corrosion primer and high solid content technology, applied in the field of paint making, can solve problems such as sag, affect production efficiency and production delivery, and fail to construct, and achieve excellent drying performance

Inactive Publication Date: 2016-01-13

成都拜迪新材料有限公司

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a result, water-based paints, solvent-free and other ultra-low VOC emission coatings ushered in spring, but the inherent construction and performance defects of water-based paints cannot be solved at present. For example: in winter, almost all temperatures in the north are below zero, and water-based paints appear The phenomenon of ice makes it impossible to construct at all. In the south, under the envir

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

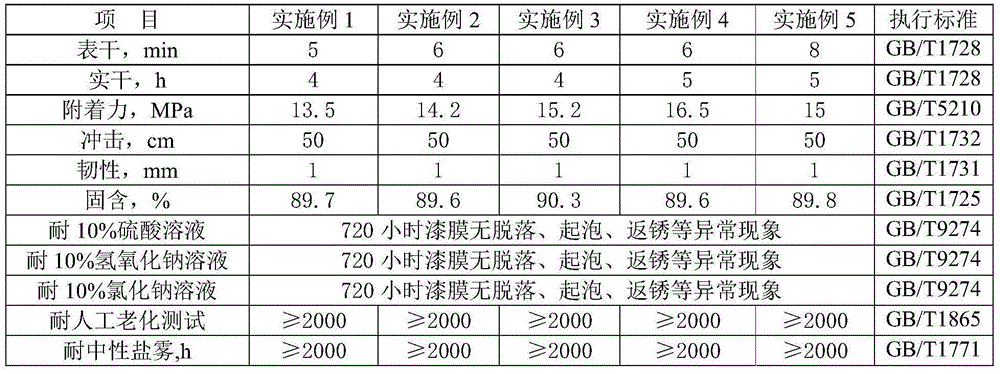

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for preparing a low-VOC (Volatile Organic Compound) high-solid-content polyurea anticorrosive primer. The anticorrosive primer contains an ingredient A and an ingredient B, wherein the ingredient A contains the following ingredients in percentage by mass (a product formula of the ingredient A): 20-30% of polyaspartate, 20-30% of micaceous iron oxide red powder, 5-10% of environment-friendly zinc phosphate, 5-10% of nano barium sulfate and 15-20% of ferrophosphorus powder; and the ingredient B is 100% isocyanate resin. A preparation process for the anticorrosive primer comprises the steps: adding polyaspartate and the like into a production cylinder, and carrying out dispersing; adding the micaceous iron oxide red powder, the environment-friendly zinc phosphate and the like into the production cylinder while carrying out stirring, then, carrying out dispersing, and carrying out grinding until the grain size is 40 microns; adding nano barium sulfate and the like into the production cylinder, and carrying out stirring; and carrying out dry-plate implementation. The invention mainly provides a standard for achieving low-VOC discharge by a common solvent-free epoxy system; and the VOC discharge capacity of the prepared coating material is completely controlled to be lower than 200mg/L, the coating material can have a very excellent drying property whether in northern winter or southern wet seasons, and meanwhile, the one-time thickness can reach over 200 microns and is free of sagging.

Description

technical field [0001] The invention relates to the field of paint making, in particular to a preparation method of a low-VOC high-solid polyurea anticorrosion primer. Background technique [0002] As the country's environmental protection requirements become more and more stringent, the country has successively issued a new "Environmental Protection Law", "consumption tax", "pollution discharge tax", and corresponding cities have issued a prohibition on the production and use of oil-based paint in order to control PM2.5. As a result, water-based paints, solvent-free and other ultra-low VOC emission coatings ushered in spring, but the inherent construction and performance defects of water-based paints cannot be solved at present. For example: in winter, almost all temperatures in the north are below zero, and water-based paints appear The phenomenon of ice makes it impossible to construct at all. In the south, under the environment of too low temperature and high humidity, w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/02C09D5/08

Inventor 江拥任明华田多

Owner 成都拜迪新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com