A press dehydrator

A dehydrator, a press-type technology, applied in mechanical equipment, washing devices, textiles and papermaking, etc., can solve problems such as insufficient use of time and energy, inability to meet the speed of dehydration of clothes, and inability to dehydrate clothes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

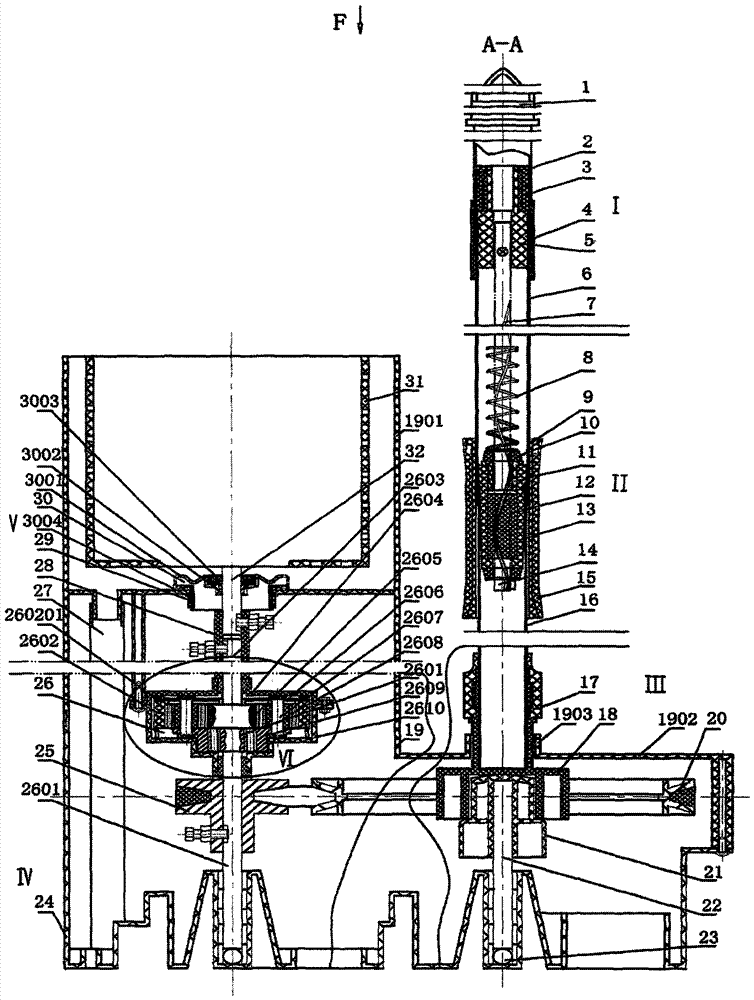

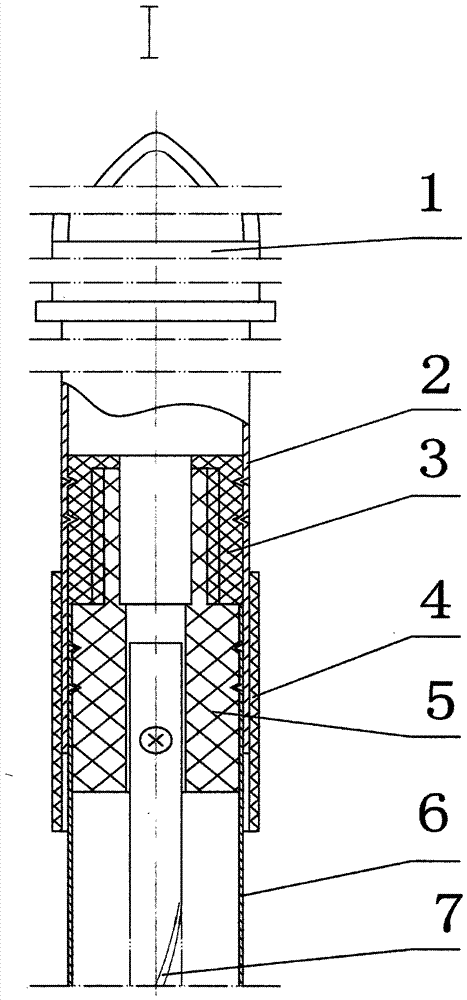

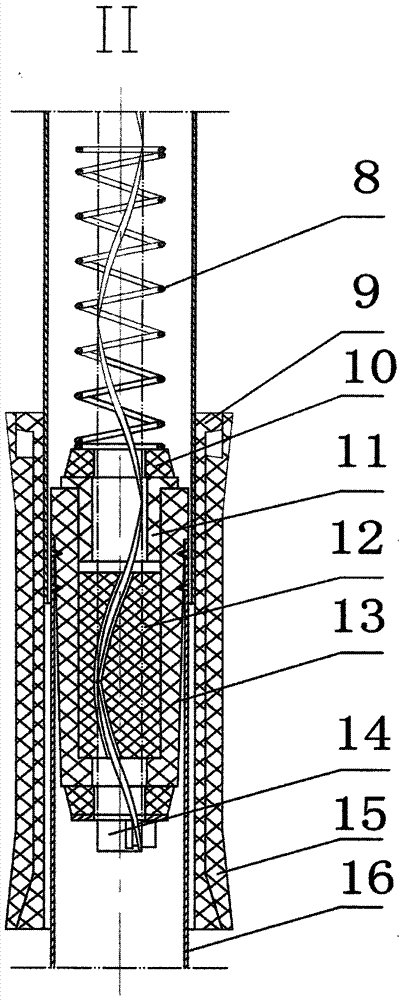

[0043] Figure 1 to Figure 3 Shows a preferred embodiment of the present invention, as shown in the figure, the press-type dehydrator of the present invention is mainly composed of a base, a pair of splined input shafts and support shafts, an outer barrel, a planetary gear speed increaser combination, It is composed of a pulley transmission mechanism, a combination of sealing water bowls, a combination of dehydration cylinders, and a combination of up and down moving and rotating devices.

[0044] The base 24 is positioned at the lowermost end of the device, and the upper end of its circumference outer wall is an outer low inner high step wall 2401 ( Figure 1-04 ), see figure 1 , figure 2 , image 3 , Figure 1-04 , Figure 1-05 , Figure 1-06 , in the illustrated embodiment, its left and right parts each have a protruding groove, the groove is a cylindrical hole, and a ball 23 is placed at the bottom of the hole. A pair of spline input shafts 2601 and support shafts 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com